Separation method of polyamide-amine dendritic compound

A technology of amine dendritic and separation method, which is applied in the field of polymer material preparation, can solve the problem of insufficient separation of reaction materials and solvents, and achieve obvious effects and reduce the residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

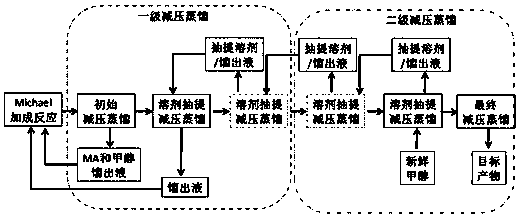

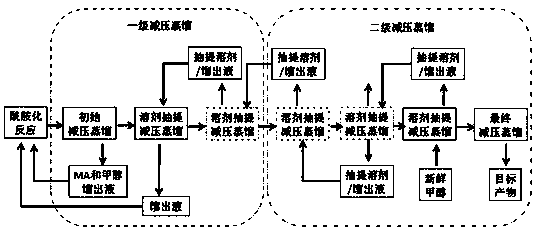

[0036] Separation and purification of semi-algebraic PAMAM G0.5: after the Michael addition reaction of semi-algebraic G0.5 preparation, it is divided into 2 parts for vacuum distillation. One part, using the semi-algebraic Michael addition reaction product vacuum distillation process (see attached figure 1 ), the specific process includes initial distillation (1.1), primary vacuum distillation (1.2) using solvent extraction, secondary vacuum distillation (2.2) using fresh methanol as extraction solvent, and the yield of the final product G0.5 is 98.8 %. Another part, using the conventional vacuum distillation process, that is, the initial distillation (1.1) process, but the operating parameters are temperature 50 ° C, vacuum ~ 101 kPa, the yield of product G0.5 is 99.2%. The method described in this patent application is more thoroughly separated than conventional methods.

[0037] Yield = product obtained by distillation under reduced pressure ÷ the amount of product obtai...

Embodiment 2

[0039] Separation and purification of semi-algebraic PAMAM G2.5: After the Michael addition reaction of semi-algebraic G2.5 is prepared, it is divided into two parts for vacuum distillation. One part, using the semi-algebraic Michael addition reaction product vacuum distillation process (see attached figure 1 ), the specific procedures include initial distillation (1.1), primary vacuum distillation using solvent extraction (1.2), secondary vacuum distillation (2.2) using fresh methanol as extraction solvent, and final vacuum distillation (temperature 54°C , vacuum ~101kPa), the yield of the final product G2.5 is 95.4%. The other part, using the conventional vacuum distillation process, that is, the initial distillation (1.1) process, but the operating parameters are temperature 50 ° C, vacuum ~ 101 kPa, the yield of the obtained product G2.5 is 105.3%. Excess reactant MA and solvent still obviously remain in the product obtained by the conventional method, but the method desc...

Embodiment 3

[0041] Separation and purification of semi-algebraic PAMAM G3.5: After the Michael addition reaction of semi-algebraic G3.5 was prepared, it was divided into two parts for vacuum distillation. One part, using the semi-algebraic Michael addition reaction product vacuum distillation process (see attached figure 1 ), the specific procedures include initial distillation (1.1), primary vacuum distillation using distillate as extraction solvent (1.2) and (1.3), secondary vacuum distillation using distillate and fresh methanol as extraction solvent (2.1) and (2.2), final vacuum distillation (temperature 54°C, vacuum ~101kPa), that is, the entire process of separation of Michael reaction products mentioned above in this patent application, the yield of the final product G3.5 is 97.7%. The other part, using the conventional vacuum distillation process, that is, the initial distillation (1.1) process, but the operating parameters are temperature 50 ° C, vacuum ~ 101 kPa, the yield of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com