Adhesive composition and optical fingerprint module

A composition and adhesive technology, which is applied in character and pattern recognition, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of complex process, low product yield, large thickness, etc., and achieve simplified process and improved The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

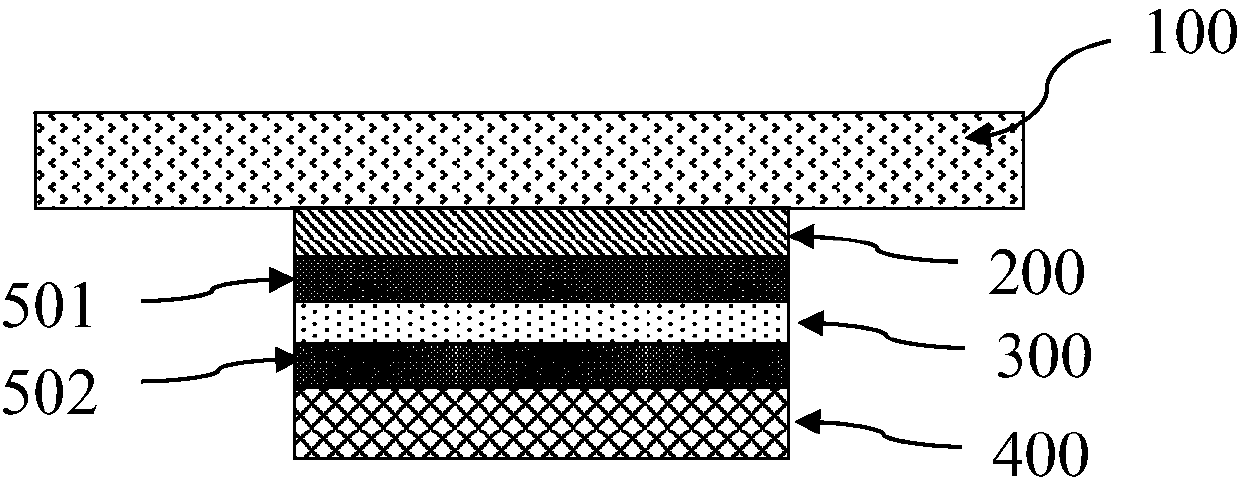

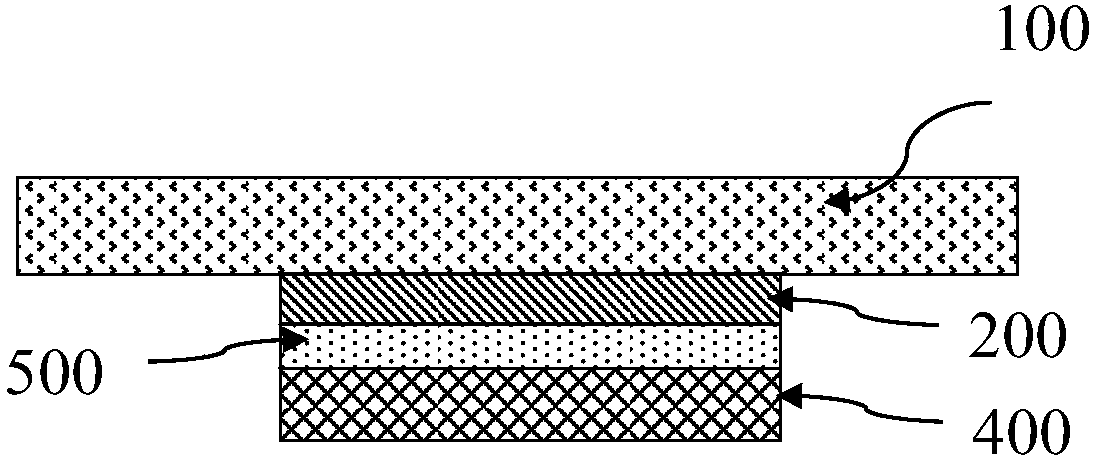

Image

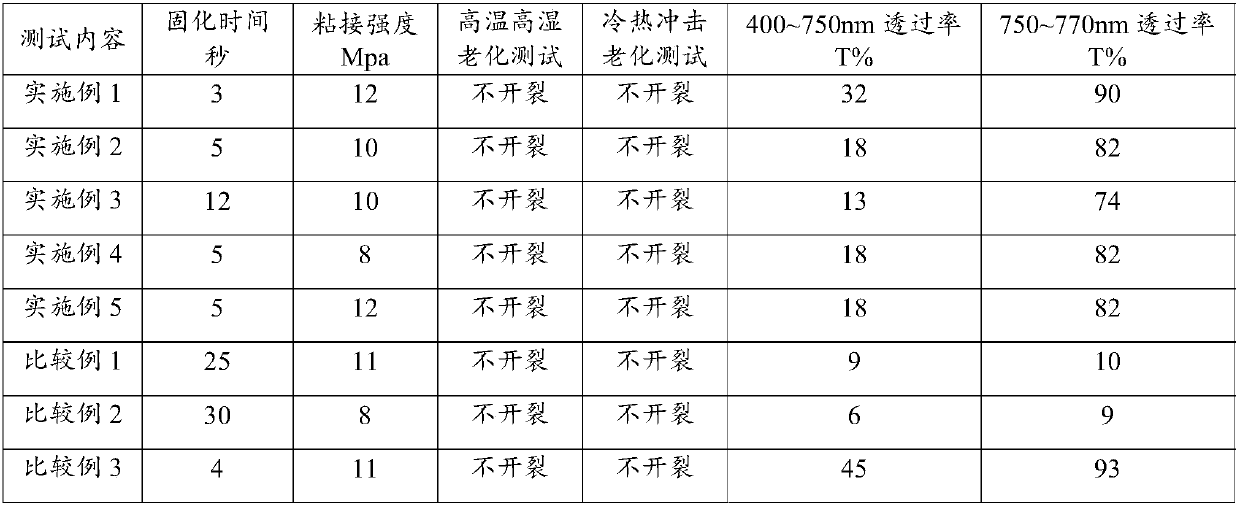

Examples

preparation example Construction

[0041] The preparation method of the adhesive composition of the present invention comprises: mixing and stirring required amounts of each component. The preparation process is carried out under normal temperature and pressure, and needs to be protected from light.

[0042] The performance of adhesive composition of the present invention is tested by following method:

[0043] Test 1: LED curing. The thickness of the dispensing glue is 0.15mm, and it is cured by an LED ultraviolet lamp, such as IGE's XC210 (wavelength 365nm). Its light intensity is 800mw / cm 2 ~1200mw / cm 2 , the time is 6 seconds to 8 seconds.

[0044] Test 2: Adhesion. It is used to characterize the strength of the adhesive composition to the sheet after it is fully cured. Usually the thickness of the adhesive layer is 50μm and the area is 5x10mm. The sheet material described here is glass. The testing equipment used was a universal tensile machine (Instron 3367, Instron Inc.). During the test, use gl...

Embodiment 1

[0053] In the first step, 55kg of aliphatic urethane acrylate, 18kg of isobornyl acrylate and 18kg of hydroxyethyl acrylate are put into the mixing tank for stirring, and the stirring speed is set at 90-120rpm, and stirred for 10 minutes; in the second step, 3kg of 1- Hydroxycyclohexyl phenyl ketone and 1kg 2,4,6-trimethylbenzoyl-diphenylphosphine oxide are thrown into the stirring tank and stirred, the stirring speed is set at 100-120rpm, and the stirring time is 20 minutes; the third Step, the visible light absorber 0.2kg of UV449, 0.2kg of UV482, 0.2kg of UV497, 0.2kg of UV546, 0.2kg of UV584, 0.2kg of UV638, 0.2kg of UV679, 0.2kg of UV709 and 0.2kg of UV740 Put it into a mixing tank and stir, the stirring speed is set to 15-30rpm, the stirring time is 25 minutes, and finally the mixture is filtered and packaged.

Embodiment 2

[0055] In the first step, put 50kg of aliphatic urethane acrylate, 18kg of isobornyl acrylate, 10kg of ethoxylated trimethylolpropane triacrylate and 10kg of hydroxypropyl acrylate into the mixing tank for stirring, and the stirring speed is set at 60- 120rpm, stirred for 10 minutes; In the second step, 2kg 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-acetone, 0.5kg isopropyl thioxanthone (2 , 4 isomers mixed), 1kg p-position N, N-dimethylaminobenzoic acid isooctyl ester and 1.5kg o-benzoyl benzoic acid methyl ester are thrown into the mixing tank and stirred, the stirring speed is set to 100-120rpm, and the stirring time is 20 minutes; the third step, the visible light absorber 0.3kg of UV449, 0.3kg of UV482, 0.3kg of UV497, 0.3kg of UV546, 0.3kg of UV584, 0.3kg of UV638, 0.3kg of UV679, 0.3kg of UV709 Put 0.3kg of UV740 into the mixing tank and stir, the stirring speed is set to 15-30rpm, the stirring time is 25 minutes, and finally the mixture can be filtered and packaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com