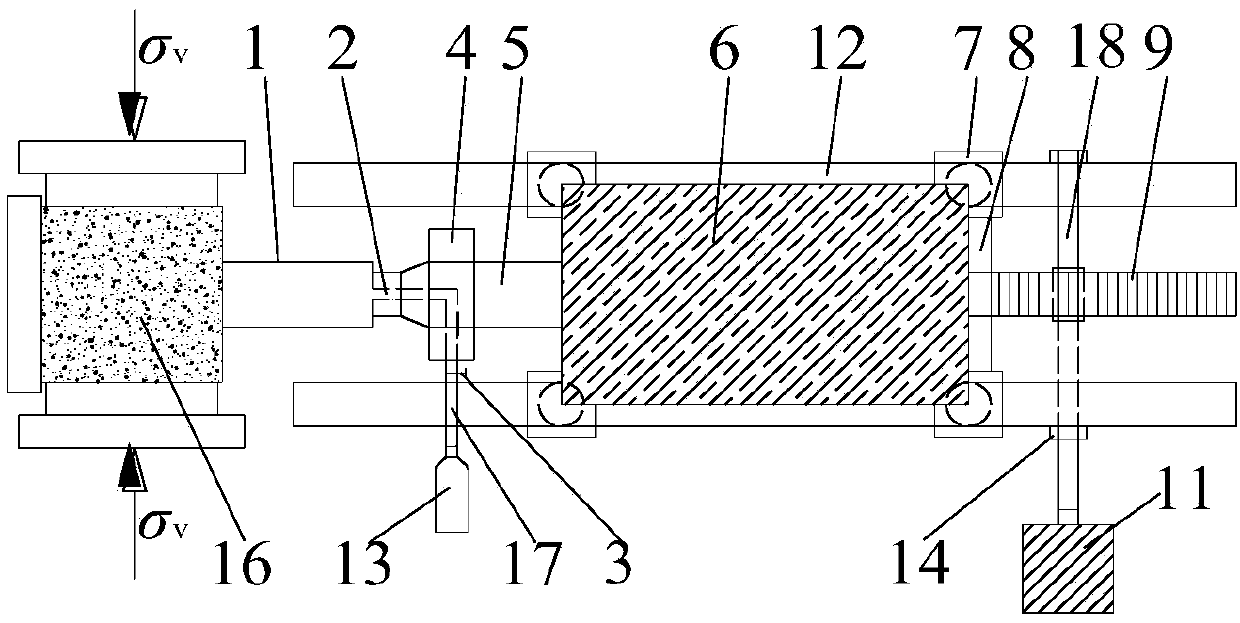

Test device and method for simulating two-dimensional loading liquid nitrogen cooling roadway excavation and unloading

A technology of excavation unloading and two-dimensional loading, which is used in measurement devices, sampling devices, and the use of stable tension/pressure to test the strength of materials, etc. problem, to achieve the effect of compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

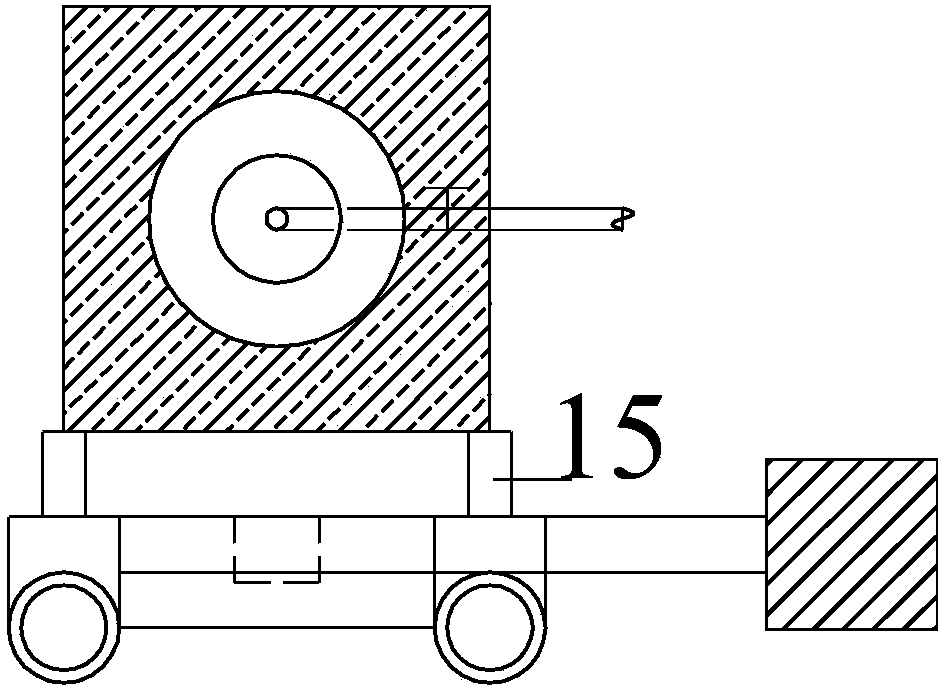

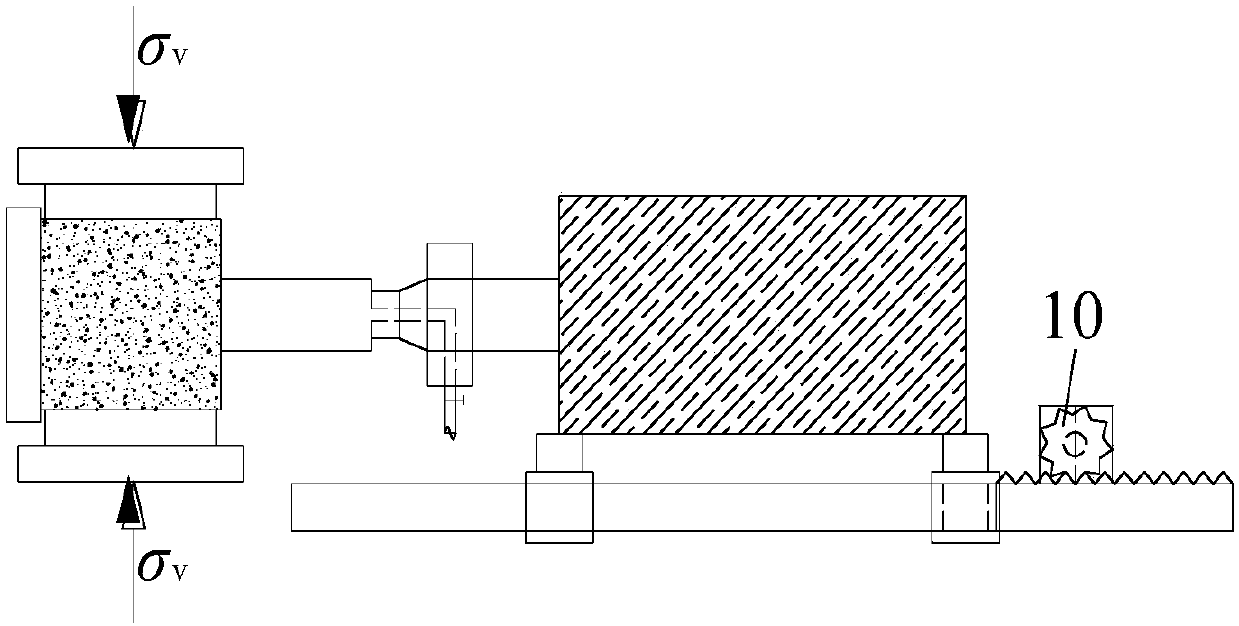

[0045] A test method for simulating the excavation and unloading of a circular roadway loaded with liquid nitrogen for cooling in two dimensions. A test device for simulating the excavation and unloading of a circular roadway for cooling in two-dimensionally loaded liquid nitrogen is used, including the following test steps:

[0046] Step 1. Fixing the rock sample 16: place the processed square rock sample 16 on the TRW-3000 rock true three-axis electro-hydraulic servo mutagenesis (disturbance) testing machine, with the vertical upper side loading block 19 and the vertical lower side loading block 20. In the loading chamber composed of the horizontal left loading block 21 and the horizontal right loading block 22, a small force is applied in the vertical direction through the control system of the testing machine, and then loaded in the horizontal direction, thereby fixing the rock sample 16, The magnitude of the force is equal to the force in the vertical direction. The testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com