Method for preparing 7-halo-6-nitro-1,4-dihydroquinoline-4-one-3-carbonitrile

A technology of dihydroquinoline and carbonitrile, which is applied in the field of organic chemical synthesis, can solve the problems of difficult production scale-up, low process safety, and harsh reaction conditions, and achieve low cost, low equipment requirements, and relatively mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

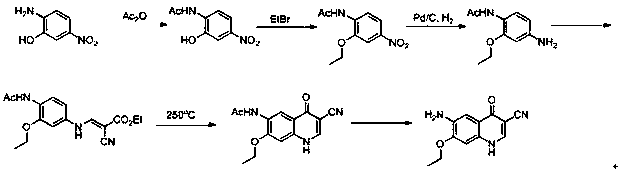

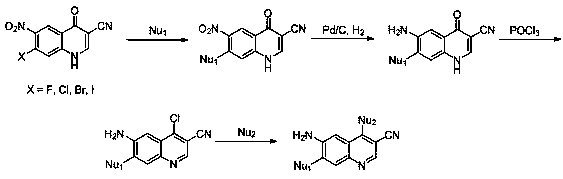

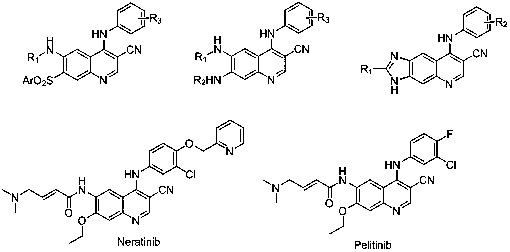

Method used

Image

Examples

Embodiment 1

[0037] 1, Synthesis of 2-amino-4-chlorobenzoic acid methyl ester

[0038] Add 10g of 2-amino-4-chlorobenzoic acid and 150ml of methanol to the one-mouth bottle, cool to 0-5°C, and add 10.4g of thionyl chloride dropwise while keeping warm. After the dropwise addition was completed, the temperature was raised to reflux and reacted for 24hrs. Cool down to room temperature, and concentrate under reduced pressure to remove methanol. Add 100ml of ethyl acetate and 100ml of 5% sodium carbonate solution, stir, let stand, separate the water layer, wash the organic layer with 100ml of water, dry over anhydrous sodium sulfate and concentrate under reduced pressure to obtain 2-amino-4-chlorobenzoic acid methyl ester 8.9 g, yield 82%.

[0039] 2, Synthesis of 4-chloro-2-((2-cyanovinyl) amino) methyl benzoate

[0040] Add 10g of 2-amino-4-chlorobenzoic acid methyl ester, 80ml of ethyl acetate, 10ml of trifluoroacetic acid into the single-necked bottle, then dropwise add 6.2g of 3-dimethy...

Embodiment 2

[0047] 1, Synthesis of 2-amino-4-bromobenzoic acid methyl ester

[0048] Add 10g of 2-amino-4-bromobenzoic acid, 150ml of methanol, and 10ml of concentrated sulfuric acid into the single-necked bottle, and heat to reflux for 24hrs. Cool down to room temperature, and concentrate under reduced pressure to remove methanol. Add 100ml of ethyl acetate, 100ml of 5% sodium carbonate solution, stir for 5mins and then let stand to separate layers, separate the water layer, wash the organic layer with 100ml of water, dry over anhydrous sodium sulfate and concentrate under reduced pressure to obtain 2-amino-4-bromobenzoic acid Methyl ester 9.16g, yield 86%.

[0049] 2. Synthesis of 4-bromo-2-((2-cyanovinyl) amino) methyl benzoate

[0050] Add 10g methyl 2-amino-4-bromobenzoate, 60ml ethyl acetate, then dropwise add 6.0g 3-dimethylaminoacrylonitrile, react at room temperature for 3-4hrs, add dropwise 60ml of water, then stir at room temperature for 2hrs , filtered, washed with a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com