Flame retardant polyurethane hard foamed plastic

A technology of foamed plastics and polyurethane, which is applied in the field of polyurethane materials, can solve the problems that are rarely seen, and achieve the effect of reducing the speed of flame propagation and benefiting flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

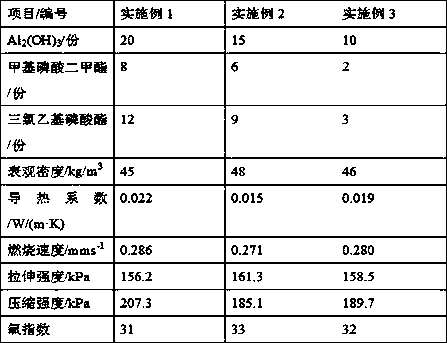

Embodiment 1

[0018] The raw materials of the flame-retardant polyurethane rigid foam are prepared according to the following parts by weight.

[0019] Weigh 40 parts of polyether polyol, 50 parts of polyester polyol, 4 parts of silicone surfactant (AK-8803) as foam stabilizer, and 2,6-di-tert-4-methylphenol as an antioxidant 3 parts, flame retardant Al 2 (OH) 3 20 parts, 8 parts of flame retardant dimethyl methyl phosphate, 12 parts of flame retardant trichloroethyl phosphate, 6 parts of chemical blowing agent water, 6 parts of physical blowing agent n-hexane, 1 part of composite catalyst, isocyanate Index 1.5 copies.

[0020] The preparation method is as follows: dry the raw materials except isocyanate at 90°C for 1 hour, cool naturally to 20°C-30°C, mix them evenly to make a combined polyether, add isocyanate and mix them, and put them into a high-speed mixer SHR-50A Stir at a high speed of 1800rpm for 5 minutes, stop stirring, put the stirred mixture into a mold for foam molding, the...

Embodiment 2

[0023] The raw materials of the flame-retardant polyurethane rigid foam are prepared according to the following parts by weight.

[0024] Weigh 37 parts of polyether polyol, 48 parts of polyester polyol, 4 parts of foam stabilizer silicone surfactant (AK-8803), and 2,6-di-tert-4-methylphenol as an antioxidant 3 parts, flame retardant Al 2 (OH) 3 15 parts, 6 parts of flame retardant dimethyl methyl phosphate, 9 parts of flame retardant trichloroethyl phosphate, 6 parts of chemical foaming agent n-pentane, 6 parts of physical foaming agent petroleum ether, 1 part of composite catalyst , Isocyanate index 2 parts.

[0025] According to the same method as in Example 1, a flame-retardant polyurethane rigid foam was prepared.

Embodiment 3

[0027] The raw materials of the flame-retardant polyurethane rigid foam are prepared according to the following parts by weight.

[0028] Weigh 45 parts of polyether polyol, 55 parts of polyester polyol, 4 parts of foam stabilizer silicone surfactant (AK-8805), 4 parts of antioxidant 2,6-di-tert-4-methylphenol , flame retardant Al 2 (OH) 3 10 parts, 2 parts of flame retardant dimethyl methyl phosphate, 3 parts of flame retardant trichloroethyl phosphate, 6 parts of chemical blowing agent cyclopentane, 6 parts of physical blowing agent trichlorofluoromethane, composite catalyst 1 part, isocyanate index 3.5 parts.

[0029] According to the same method as in Example 1, a flame-retardant polyurethane rigid foam was prepared.

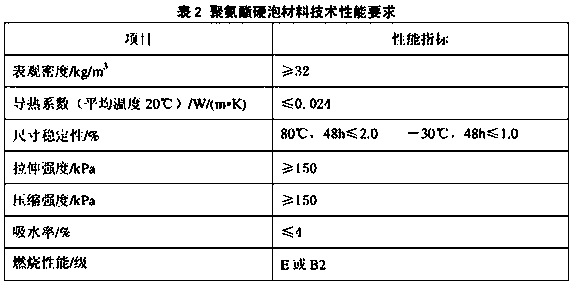

[0030] 1. Performance testing.

[0031] 1. Testing and Characterization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com