Method for preparing polyethylene-polyvinyl acetate elastomer soap-free microemulsion

A polyvinyl acetate and vinyl acetate technology, applied in the field of preparing EVA elastomer microemulsion, can solve the problems of poor particle shape and emulsion stability, limited product application range, increase production cost and other problems, and achieve improved emulsion stability, The effect of reducing the particle size of latex particles and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

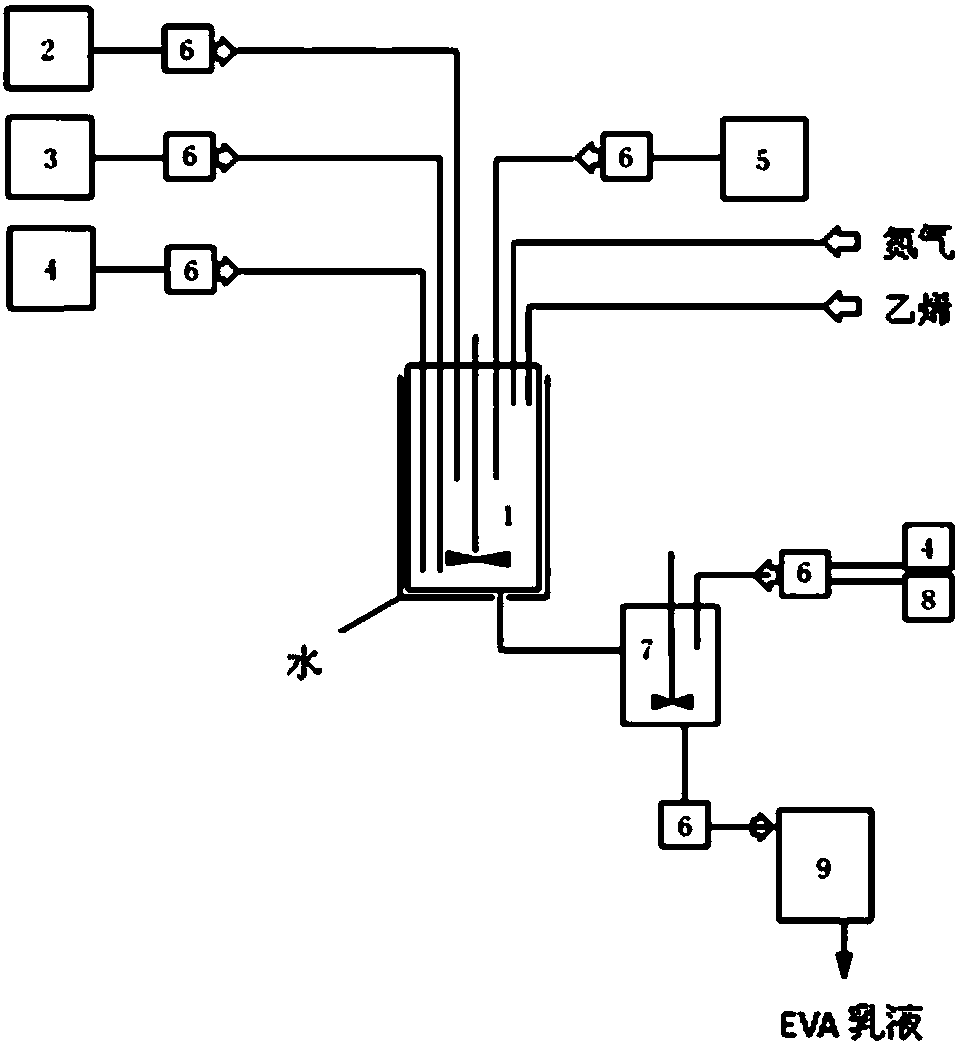

Image

Examples

Embodiment 1

[0031] Using ammonium persulfate as the initiator, the total amount is 0.5wt% of vinyl acetate, O / W system, the volume ratio of butanone and methanol is 10 / 1; the volume ratio of the mixed solvent to the water phase of the copolymerization system is 1 / 10, the system Before adding monomer VAc, the mechanical stirring speed was 300r / min; when monomer VAc was added, the mechanical stirring speed was 150r / min; the dosage of pH regulator was 0.5wt% of the monomer VAc dosage; MPa, the polymerization reaction time is 6h. Under this condition, the VAc content of the polymerization product is 62.1wt%, and the particle size of the emulsion is 50nm. The emulsion has good stability and can be stored stably for 13 months.

Embodiment 2

[0033] Using ammonium persulfate as the initiator, the total dosage is 0.5wt% of vinyl acetate, O / W system, the volume ratio of butanone and methanol is 9 / 2; the volume ratio of the mixed solvent to the water phase of the copolymerization system is 1 / 10, the system Before adding monomer VAc, the mechanical stirring speed was 300r / min; when monomer VAc was added, the mechanical stirring speed was 150r / min; the dosage of pH regulator was 0.5wt% of the monomer VAc dosage; MPa, the polymerization reaction time is 6h. Under this condition, the VAc content of the polymerization product is 62.2wt%, and the particle size of the emulsion is 64nm. The emulsion has good stability and can be stored stably for 12 months.

Embodiment 3

[0035] Using ammonium persulfate as the initiator, the total amount is 0.5wt% of vinyl acetate, O / W system, the volume ratio of butanone and methanol is 8 / 3; the volume ratio of the mixed solvent to the water phase of the copolymerization system is 1 / 10, the system Before adding monomer VAc, the mechanical stirring speed was 300r / min; when monomer VAc was added, the mechanical stirring speed was 150r / min; the dosage of pH regulator was 0.5wt% of the monomer VAc dosage; MPa, the polymerization reaction time is 6h. Under this condition, the VAc content of the polymerization product is 62.3wt%, and the particle size of the emulsion is 76nm. The emulsion has good stability and can be stored stably for 12 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com