A kind of preparation method and application of sheet-fed offset printing ink with low voc content

A content and ink technology, applied in the field of sheet-fed offset printing ink preparation, can solve the problems of improved dryness, reduced ink viscoelasticity, poor solvent release, etc., and achieve good pigment wettability, good dryness, and fluidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The specific formula of the environmentally friendly high-gloss quick-drying fatty acid methyl ester type offset printing ink of the present embodiment is shown in figure 1 .

Embodiment 2

[0047] The specific formula of the environmentally friendly high-gloss quick-drying fatty acid methyl ester type offset printing ink of the present embodiment is shown in figure 2 .

Embodiment 3

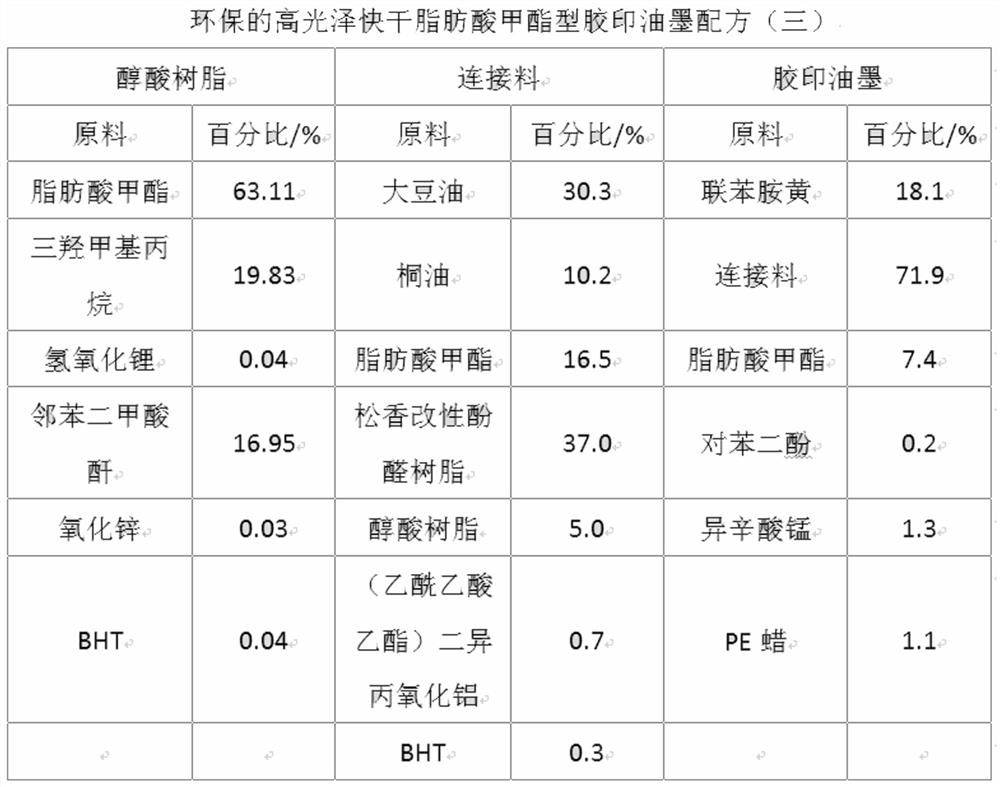

[0049] The specific formula of the environmentally friendly high-gloss quick-drying fatty acid methyl ester type offset printing ink of the present embodiment is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com