Pore sealing agent and pore sealing process for improving long-term corrosion resistance of supersonic speed flame sprayed iron-based amorphous coating

A supersonic flame, iron-based amorphous technology, applied in metal material coating process, coating, melting spraying and other directions, can solve the problem of inability to achieve sealant sealing, achieve good storage stability, convenient operation, improve The effect of long-term corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation process of the supersonic flame spraying iron-based amorphous coating used in the present embodiment is as follows:

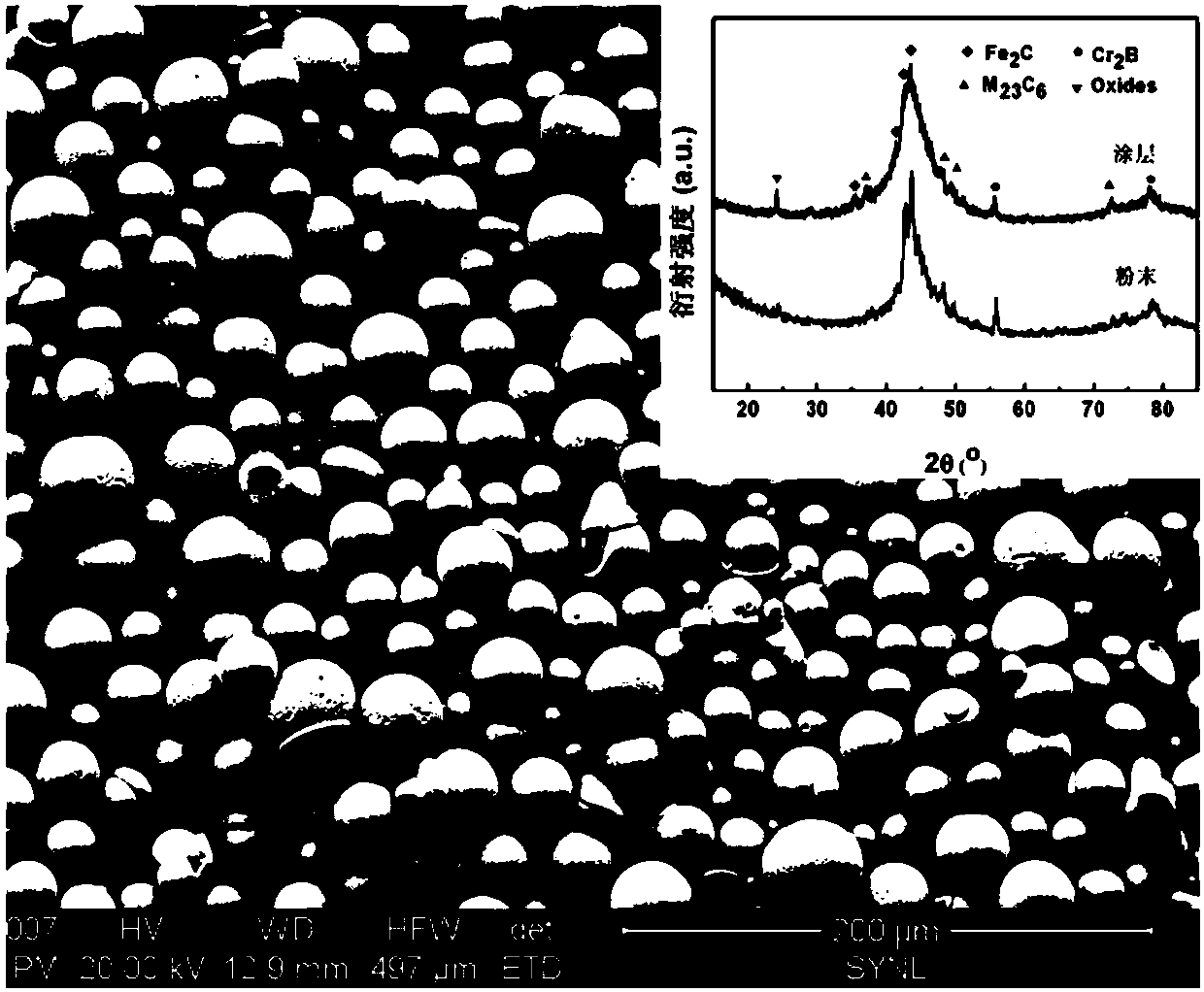

[0029] Amorphous powders were prepared by ultrasonic gas atomization equipment. The shape of the powder particles is as figure 1 . It can be seen from the figure that the powder is mostly spherical with a small amount of satellite tissue. The fluidity of the powder is 16.8s / 50g, suitable for HVAF supersonic flame spraying. The powder is amorphous with a small amount of amorphous phase.

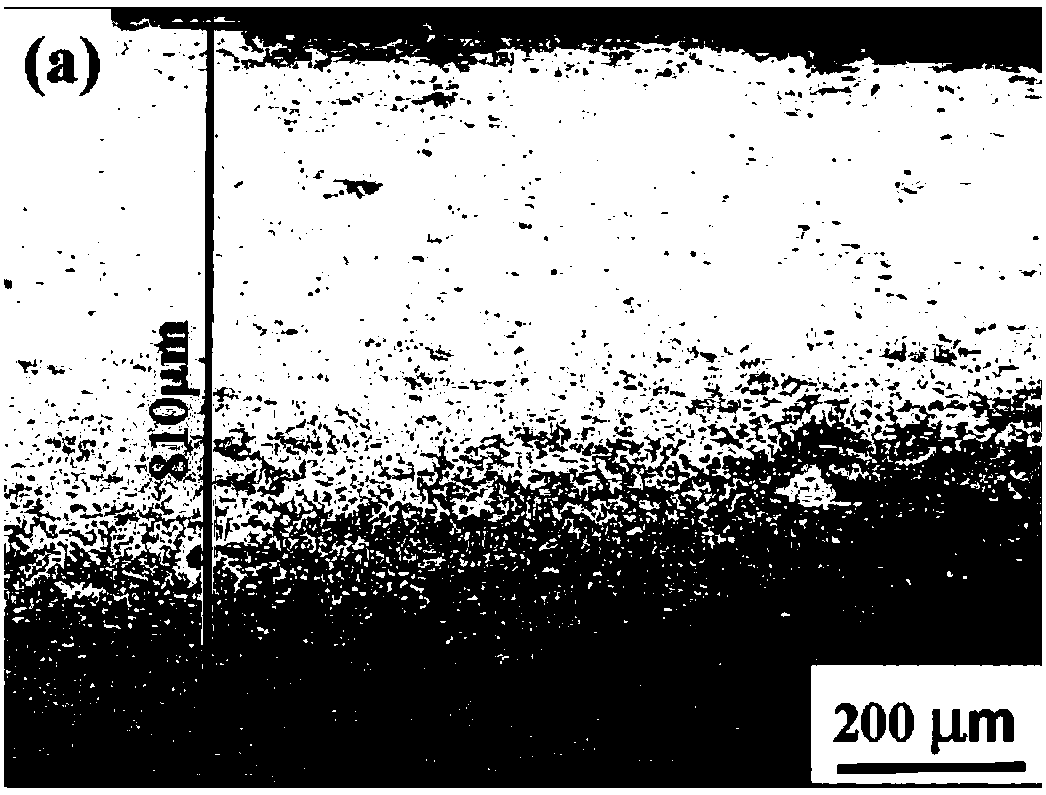

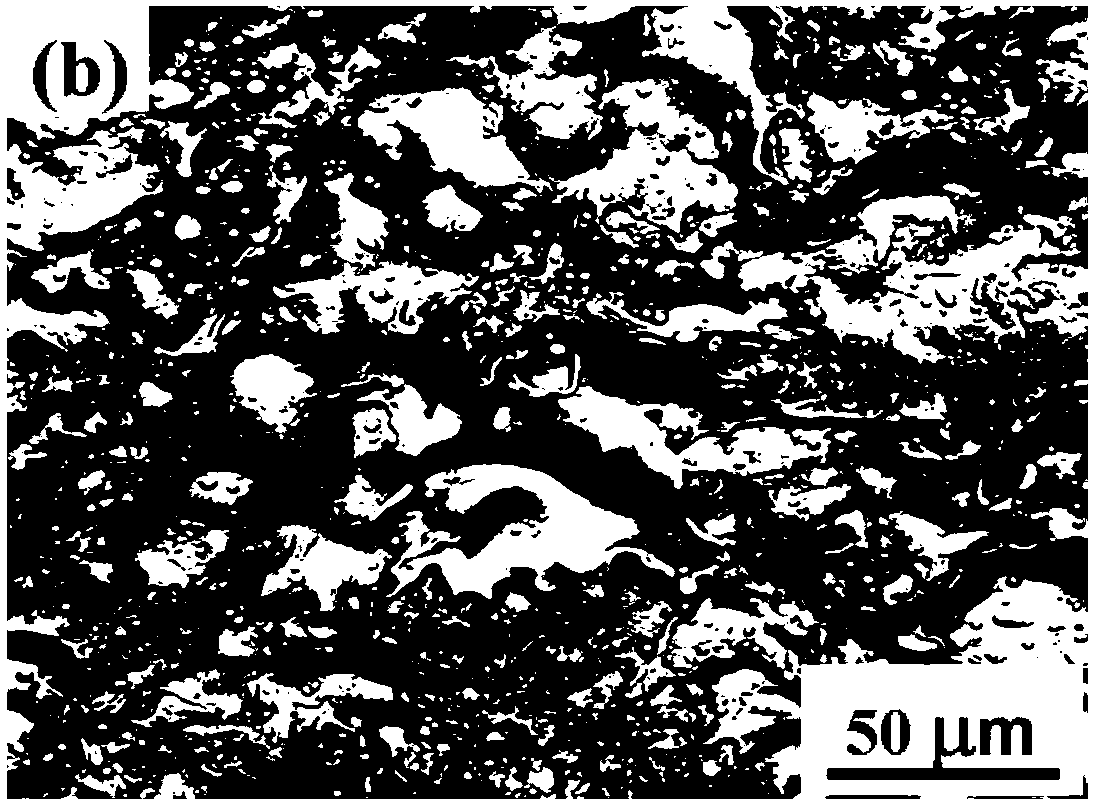

[0030] The above-mentioned powder (with a particle size of 15 μm to 52 μm) is used as a spraying raw material, and an amorphous alloy coating (the base is ordinary carbon steel) is prepared by using HVAF supersonic flame spraying equipment. First, the substrate is degreased and derusted, and the surface of the substrate is blasted with a spray gun to increase the roughness of the surface. The specific process parameters of HVAF supersonic flame spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluidity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com