Solid waste pulverizing and high-temperature incineration device

An incineration device and high-temperature technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of low combustion rate, inability to automatically adjust the size, and large volume of ash in the integration of crushing and incineration, so as to facilitate crushing and incineration , The effect of reducing the volume of ash and reducing the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

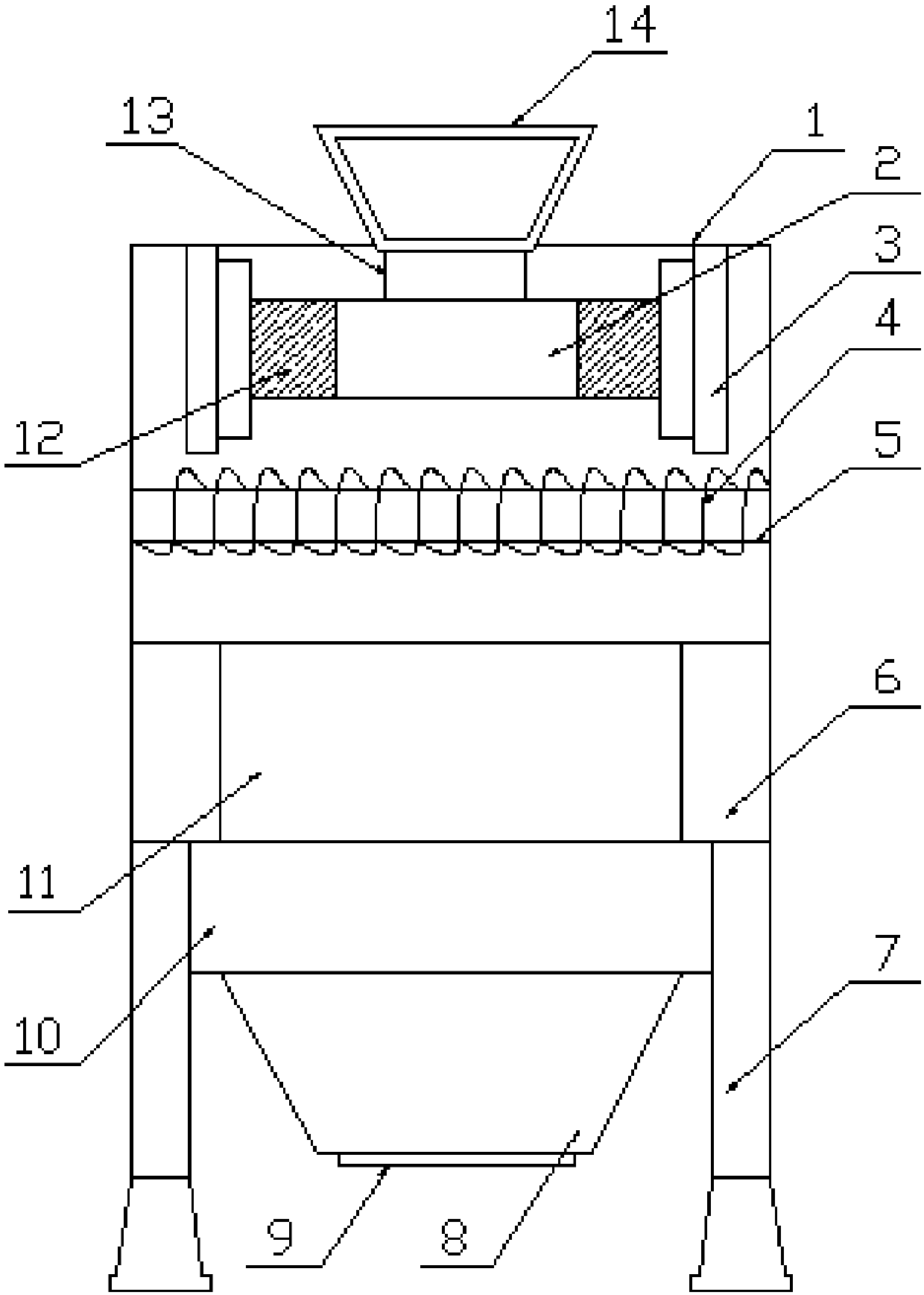

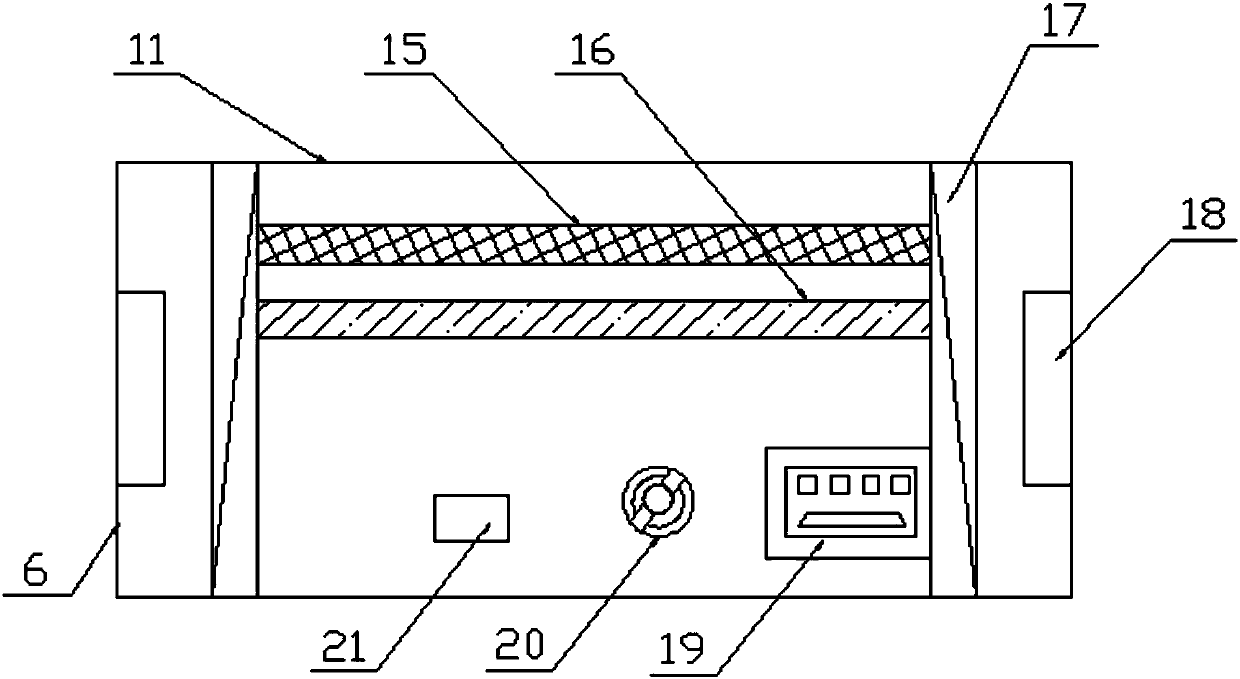

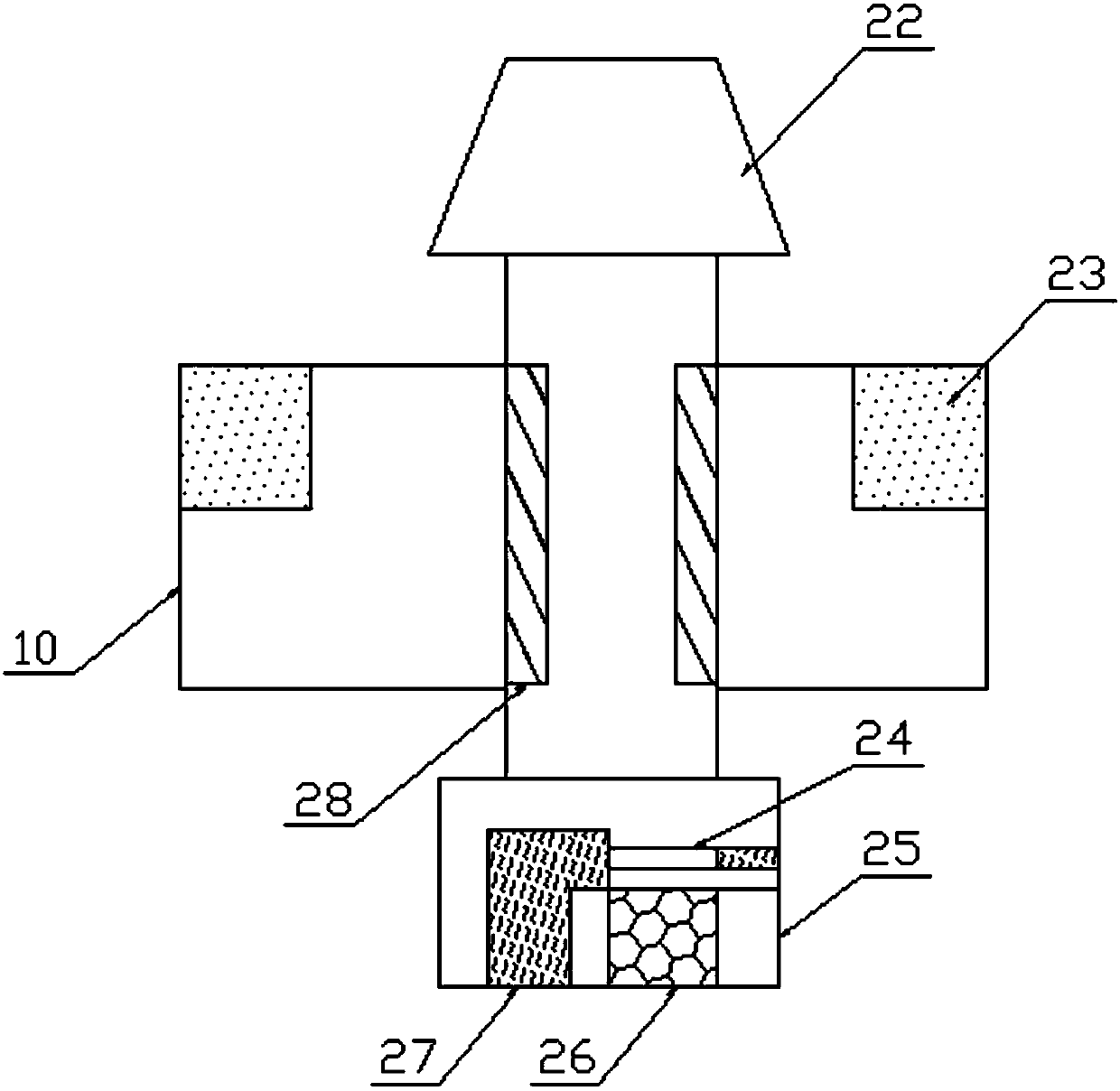

[0016] Such as Figure 1-Figure 3 As shown, a solid waste crushing high-temperature incineration device mainly includes a chassis 1, the upper end of the chassis 1 is provided with a feed port 14, the lower end of the chassis 1 is provided with an extrusion channel 13, and the lower end of the extrusion channel 13 is provided with a dehydration extrusion machine room 2. Some solid waste may have a certain amount of moisture, which is difficult to handle. Through the dehydration extrusion machine chamber 2, part of the moisture can be squeezed dry, which is convenient for crushing and incineration. Both sides of the dehydration extrusion chamber 2 are equipped with Oxygen-enriched air supply device 12, drive mechanism 3 is provided on both sides of oxygen-enriched air supply device 12, rotating shaft 5 is provided at the lower end of dehydration extruder chamber 2, and crushing cutter 4 is provided on the surface of rotating shaft 5, and the crushing tool 4 is arranged on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com