Tin sulfide-titanium dioxide compound and preparation method and application thereof

A technology of titanium dioxide and tin disulfide, applied in the field of tin disulfide-titanium dioxide composite and its preparation, can solve problems such as poor structural stability and volume expansion, and achieve the effects of low cost, avoiding processing steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

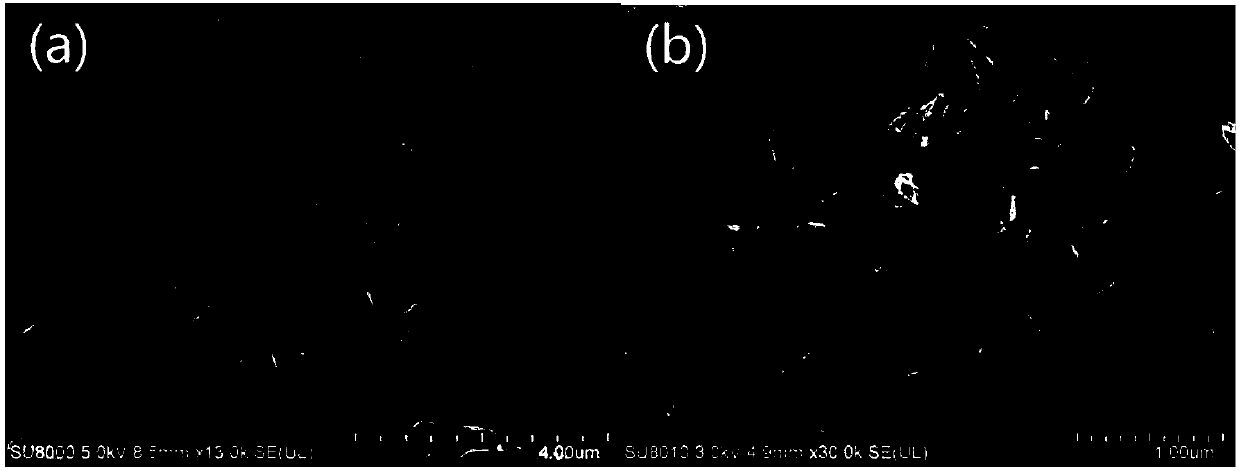

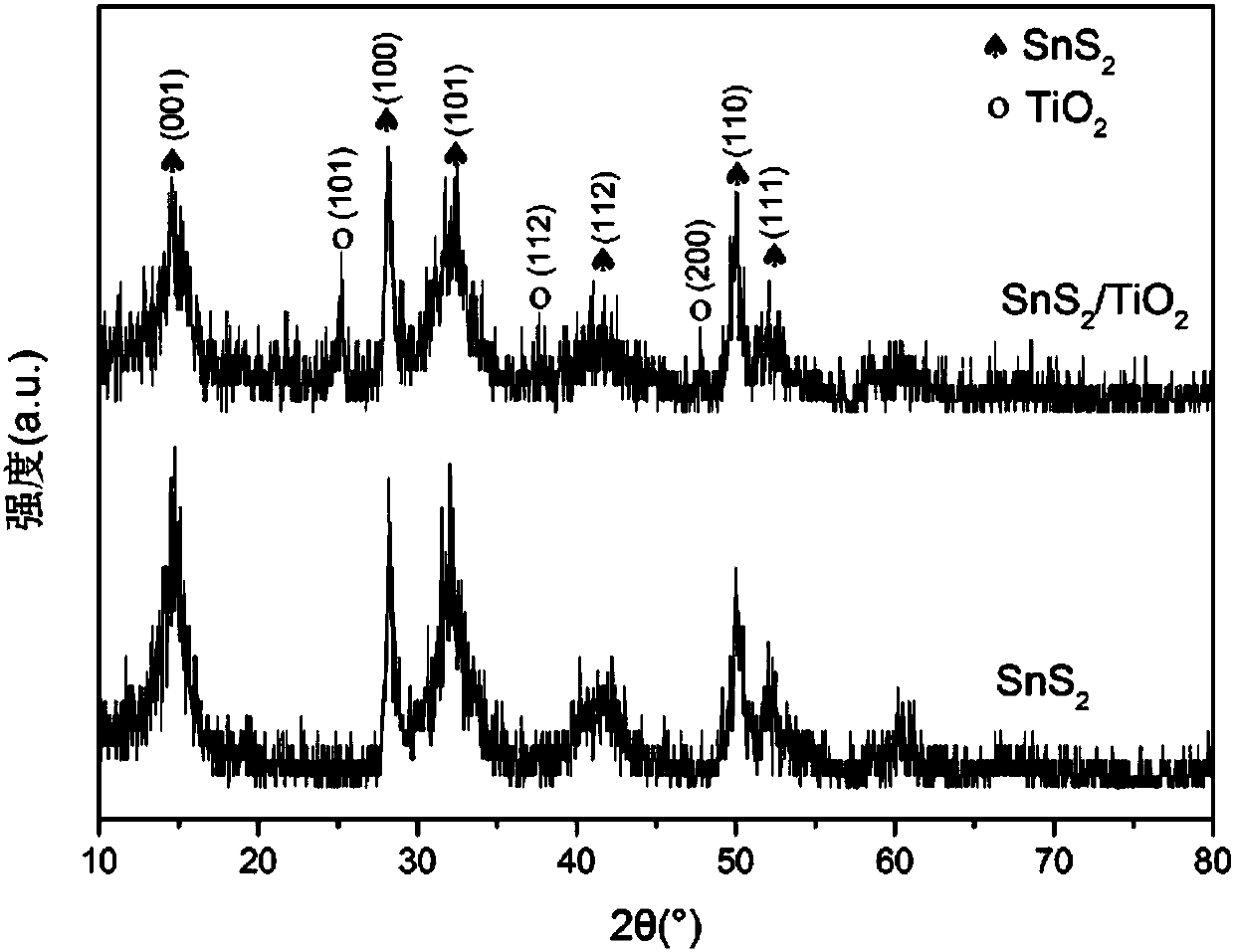

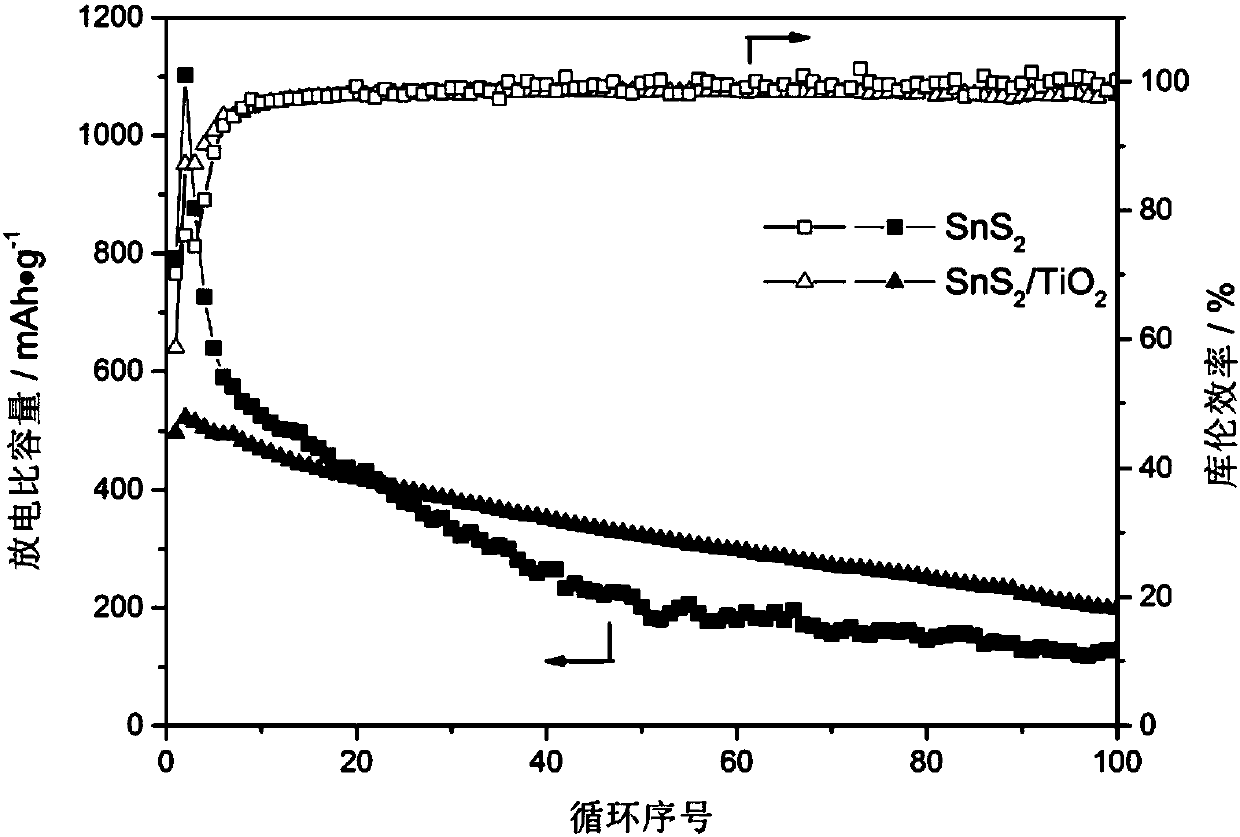

[0031] (1) 0.235g (2.94mmol) spindle-shaped nano-TiO prepared by hydrothermal method 2 , 1.400g (3.99mmol) tin chloride pentahydrate (SnCl 4 ·5H 2 O) and 1.500g (20mmol) thioacetamide (CH 3 CSNH 2 ) was dispersed in absolute ethanol, and at room temperature, magnetically stirred for 1 h to prepare a suspension;

[0032] (2) Transfer the suspension obtained in step (1) to a 200ml high-pressure hydrothermal reaction kettle, seal it well, heat up to 160°C in a heating box and keep it warm for 12h, then cool naturally;

[0033] (3) The turbid liquid obtained in step (2) was filtered to collect the precipitate, washed three times with deionized water and absolute ethanol, and then vacuum-dried at 80° C. for 12 hours to obtain the tin disulfide-titanium dioxide composite (SnS 2 / TiO 2 ).

[0034] SnS for comparison 2 The preparation method:

[0035] No spindle-shaped nano-TiO was added in step (1) 2 , repeating steps (1)-(3) to obtain the comparison product coiled SnS 2 .

...

Embodiment 2

[0043] (1) 0.235g of spindle-shaped nano-TiO prepared by hydrothermal method 2 , 1.400g tin chloride pentahydrate (SnCl 4 ·5H 2 O) and 1.500g thioacetamide (CH 3 CSNH 2 ) was dispersed in absolute ethanol, and at room temperature, magnetically stirred for 1 h to prepare a suspension;

[0044] (2) Transfer the suspension obtained in step (1) to a 200ml high-pressure hydrothermal reactor, seal it well, heat it up to 170°C in a heating box and keep it warm for 12 hours, then cool it down naturally;

[0045] (3) The turbid liquid obtained in step (2) was filtered to collect the precipitate, washed three times with deionized water and absolute ethanol, and then vacuum-dried at 80° C. for 12 hours to obtain the tin disulfide-titanium dioxide composite (SnS 2 / TiO 2 ).

[0046] SnS for comparison 2 The preparation method:

[0047] No addition of nano-spindle TiO in step (1) 2 , repeating steps (1)-(3) to obtain the comparison product coiled SnS 2 .

[0048] SnS obtained in...

Embodiment 3

[0054] (1) 0.235g of nano-spindle TiO prepared by hydrothermal method 2 , 1.400g tin chloride pentahydrate (SnCl 4 ·5H 2 O) and 1.500g thioacetamide (CH 3 CSNH 2 ) was dispersed in absolute ethanol, and at room temperature, magnetically stirred for 1 h to prepare a suspension;

[0055] (2) Transfer the suspension obtained in step (1) to a 200ml high-pressure hydrothermal reactor, seal it well, raise the temperature to 160°C in a heating box, keep it warm for 18 hours, and then cool it down naturally;

[0056] (3) The turbid liquid obtained in step (2) was filtered to collect the precipitate, washed three times with deionized water and absolute ethanol, and then vacuum-dried at 80° C. for 12 hours to obtain the tin disulfide-titanium dioxide composite (SnS 2 / TiO 2 ).

[0057] SnS for comparison 2 The preparation method:

[0058] No addition of nano-spindle TiO in step (1) 2 , repeating steps (1)-(3) to obtain the comparison product coiled SnS 2 .

[0059] SnS obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com