Heat-insulation stealthy high-temperature-resistant gas inlet duct and production method thereof

An air inlet, high temperature resistant technology, applied in the field of aircraft stealth, can solve the problems of not considering the stealth performance requirements of the air inlet, the limited radar wave absorbing effect, the high density of wave absorbing paint, etc., so as to solve the problem of heat insulation and stealth integration. , The preparation method is effective and feasible, and the low frequency absorbing performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

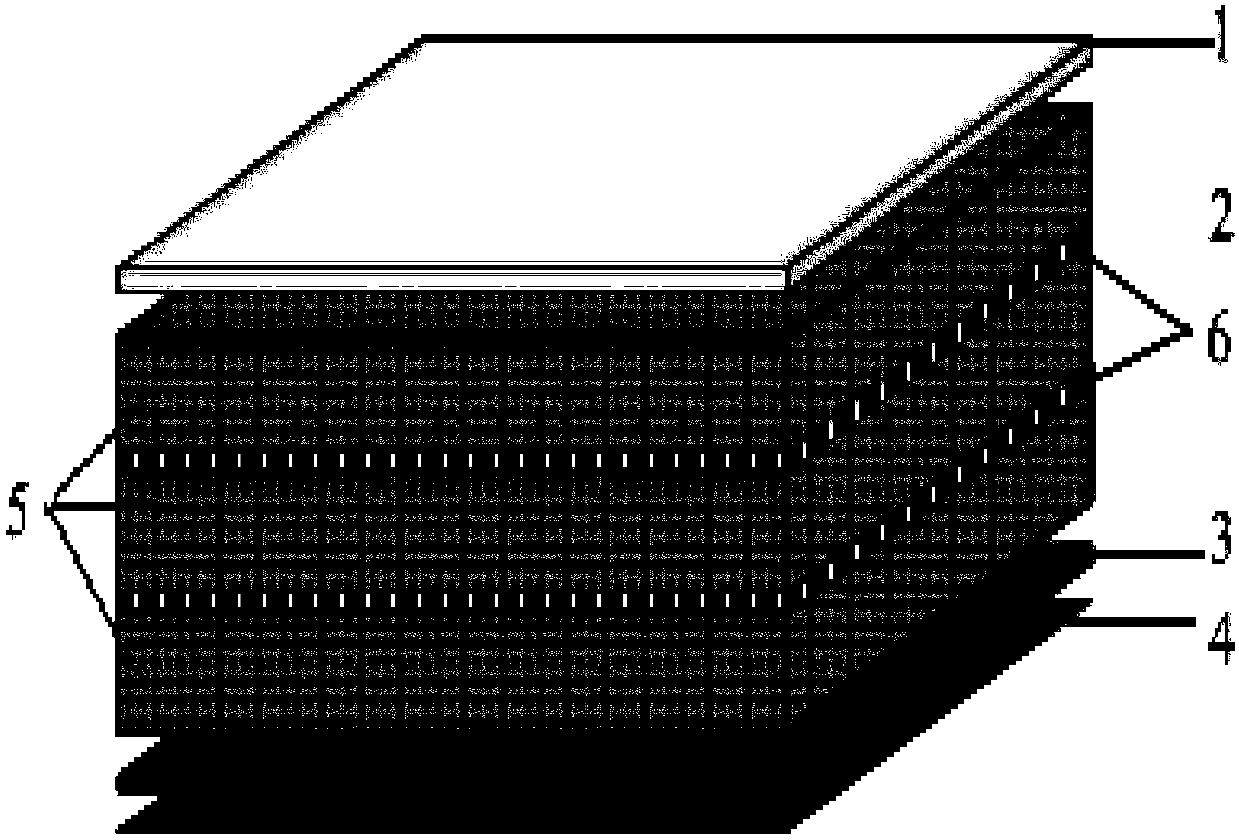

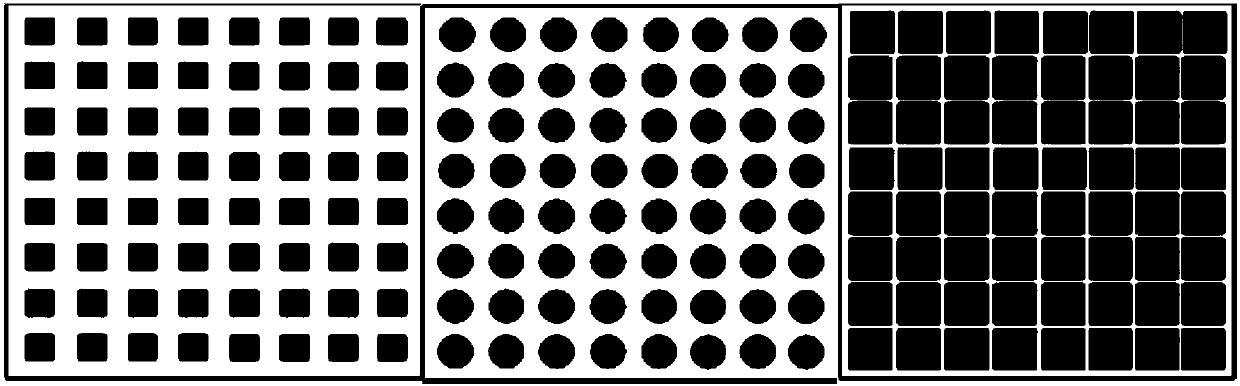

[0027] Embodiment 1: (two layers of heat insulation core layer, one layer of electromagnetic periodic structure)

[0028] Step 1: Prepare the insulating core layer

[0029] Preparation of SiO by Sol-Gel Process 2 wet gel. According to the matching design requirements, according to the order that the SiC fiber accounts for 0.05% and 2% of the volume of the heat insulation layer from the inside to the outside, add SiC fibers (dielectric real part is 3~12, imaginary part is 0~ 18) Stir well. SiO 2 The fiber mat is impregnated into the wet gel as a reinforcement, and the SiO with a dielectric constant gradually increasing from the inside to the outside is prepared by a supercritical drying process. 2 Fiber Mat Reinforced SiO 2 Airgel insulation composites. to SiO 2 The airgel insulation composite material is subjected to 500°C air atmosphere high-temperature heat treatment to remove residual organic matter and carbon impurities, and hydrophobic treatment is performed to red...

Embodiment 2

[0036] Embodiment 2: (three-layer heat insulation core layer, two-layer electromagnetic periodic structure)

[0037] Step 1: Prepare the insulating core layer

[0038]Preparation of Al by Sol-Gel Process 2 o 3 wet gel. According to the matching design requirements, according to the heat insulation layer from the inside to the outside, the SiC fiber accounts for the volume of the heat insulation layer in the order of 0.01%, 0.2% and 5% respectively. Part is 0~18) Stir evenly. Will Al 2 o 3 The fiber mat was impregnated into the wet gel as a reinforcement, and the Al with a dielectric constant gradually increasing from the inside to the outside was prepared by a supercritical drying process. 2 o 3 Fiber Mat Reinforced Al 2 o 3 Airgel insulation composites. to Al 2 o 3 The airgel thermal insulation composite material undergoes high-temperature heat treatment to remove residual organic matter and carbon impurities, and performs hydrophobic treatment to reduce the hydro...

Embodiment 3

[0045] Embodiment 3: (four layers of heat insulation core layer, three layers of electromagnetic periodic structure)

[0046] Step 1: Prepare the insulating core layer

[0047] SiN wet gels were prepared by sol-gel process. According to the matching design requirements, according to the heat insulation layer from the inside to the outside, the SiC fiber accounts for the volume of the heat insulation layer in the order of 0.01%, 0.2%, 2% and 4.5%, and the SiC fiber (dielectric real part is 3~ 12, the imaginary part is 0-18) Stir evenly. The SiN fiber mat was impregnated into the wet gel as a reinforcement, and the SiN airgel thermal insulation composite material reinforced with SiN fiber mat with a dielectric constant gradually increasing from the inside to the outside was prepared by supercritical drying process. Carry out high-temperature heat treatment on the SiN airgel thermal insulation composite material to remove residual organic matter and carbon impurities, and carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com