Concrete pumping agent and preparation method thereof

A concrete pump and water reducing agent technology, applied in the field of building materials manufacturing, can solve the problems of being unsuitable for large-scale industrial use and low cohesion, and achieve the effects of wide application range, good water reducing performance and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

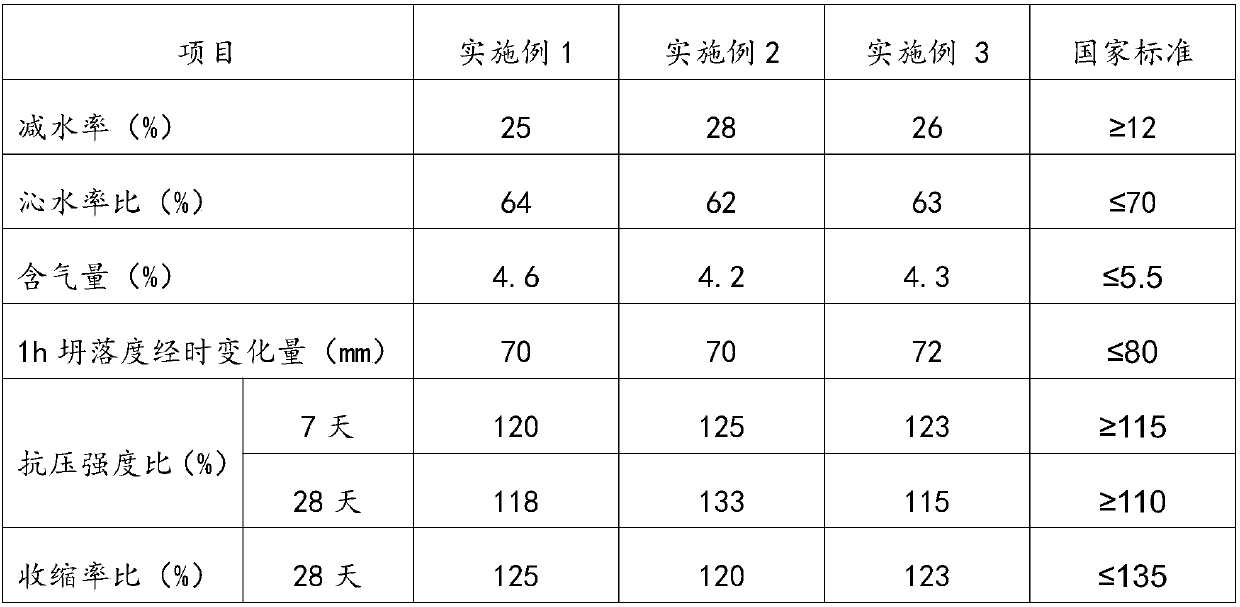

Examples

Embodiment 1

[0023] The concrete pumping agent of the present embodiment is made up of the raw material of following weight: hydroxyethyl methylcellulose 20kg, polycarboxylate superplasticizer 15kg, sodium gluconate 4kg, tetraethyl orthosilicate 9kg, hexosaccharated dicalcium 4kg, perfluorooctyltriethoxysilane 4kg, polyvinyl alcohol 1kg and water 20kg, wherein, the polycarboxylate water reducer is made up of the raw material of following weight: allyl ether 20kg, acrylic acid 15kg, ammonium persulfate 2kg and mercapto acid 4kg.

[0024] The preparation method of above-mentioned concrete pumping agent, comprises the steps:

[0025] (1) Weigh the following raw materials: hydroxyethyl methylcellulose 20kg, polycarboxylate superplasticizer 15kg, sodium gluconate 4kg, tetraethyl orthosilicate 9kg, dicalcium hexosaccharate 4kg, perfluorooctyl Triethoxysilane 4kg, polyvinyl alcohol 1kg and water 20kg;

[0026] (2) Add water to the mixer first, then add hydroxyethyl methylcellulose, polycarboxyl...

Embodiment 2

[0028] The concrete pumping agent of the present embodiment is made up of the raw materials of following weight: hydroxyethyl methylcellulose 25kg, polycarboxylate superplasticizer 10kg, sodium gluconate 6kg, tetraethyl orthosilicate 6kg, hexosaccharated dicalcium 7kg, perfluorooctyl triethoxysilane 3kg, polyvinyl alcohol 2kg and water 15kg, wherein, the polycarboxylate water reducer is made up of the following raw materials of weight: allyl ether 30kg, acrylic acid 10kg, ammonium persulfate 3kg and mercapto acid 3kg.

[0029] The preparation method of above-mentioned concrete pumping agent, comprises the steps:

[0030] (1) Weigh the following raw materials: hydroxyethyl methylcellulose 25kg, polycarboxylate superplasticizer 10kg, sodium gluconate 6kg, tetraethyl orthosilicate 6kg, dicalcium hexosaccharate 7kg, perfluorooctyl Triethoxysilane 3kg, polyvinyl alcohol 2kg and water 15kg;

[0031] (2) Add water to the mixer first, then add hydroxyethyl methylcellulose, polycarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com