Chloromethyl isopropyl carbonate continuous reaction device and method

A chloromethyl isopropyl carbonate, chemical reaction technology, applied in the field of chloromethyl isopropyl carbonate continuous reaction device, can solve the problems of waste water, consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

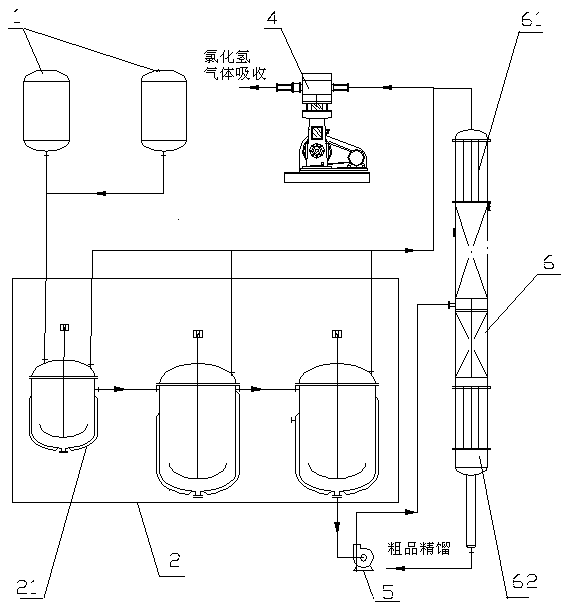

Image

Examples

Embodiment 1

[0018] Embodiment 1, in the rectifying tower of the combination of 3 sets of 2000L reactors connected in series and a DN800*16000 meter high tower, drop into chloromethyl chloroformate 260.08kg / h per hour, Virahol 174.41kg / h h, the temperature of the three-stage reactor is controlled at 40 degrees, the temperature at the bottom of the rectification tower is controlled at 80 degrees, the temperature at the top of the tower is controlled at -20 degrees, the vacuum degree of the system is -0.07MPa, and the quality of the final crude product is 366.76kg / h. The remaining unreacted S05 is 63.70 kg / h, and the mass of hydrogen chloride gas pumped out from the vacuum pump is 66.54 kg / h, with a content of about 99%.

Embodiment 2

[0019] Embodiment 2, in the reactor of 3 2000L reactors connected in series and a DN800*16000 meter high tower combination, drop into chloromethyl chloroformate 195.06kg / h per hour, Virahol 130.80kg / h , the temperature of the three-stage reactor is controlled at 40 degrees, the temperature at the bottom of the deacidification tower is controlled at 80 degrees, the temperature at the top of the tower is controlled at -20 degrees, and the vacuum degree of the system is -0.07MPa. The quality of the final crude product is 274.03kg / h. The remaining S05 of the reaction is 47.02kg / h, and the mass of hydrogen chloride gas pumped out from the vacuum pump is 49.21 kg / h, with a content of about 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com