Feature library-based complex curved surface part mechanical arm machining system and method

A complex surface and processing system technology, applied in the field of complex surface parts robotic arm processing system, can solve the problems of incomplete information data chain, lack of CAM system and robotic arm processing language interface, and difficulty in universal milling processing of robotic arms. Achieve the effect of improving milling efficiency and application efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

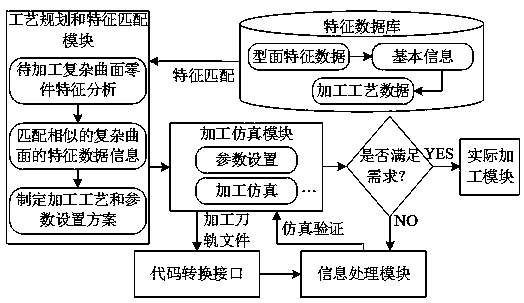

[0034] Embodiment 1: as figure 1 As shown, a complex curved surface part manipulator processing system based on feature database, including: feature database, process planning and feature matching module, code conversion interface, information processing module, processing simulation module and actual processing module.

[0035] Among them, the feature database is a collection of feature data of multiple representative complex surfaces, which is responsible for providing similar complex surface feature data information for the feature data matching process, and for the formulation of processing technology plans, as well as processing types, tool types, and machine tools. The selection of process parameters and methods related to the milling process of parts such as types and cutting parameters provides a reference basis. On the one hand, the feature data in the feature database can obtain different types of complex surface characteristic data through testing experiments. On the...

Embodiment 2

[0041] Embodiment 2: According to the system in embodiment 1, the method for processing complex curved surface parts with a mechanical arm includes: obtaining basic information of complex curved surfaces by matching similar surface feature data, and then obtaining processing technology data of complex curved surfaces through basic information; In the process planning and feature matching module, the feature analysis of the complex surface parts to be processed is carried out, the complex surface is matched according to the surface feature data of the parts to be processed, and the corresponding processing technology data is mapped, the processing technology plan is formulated according to the processing technology data, and the processing Type, tool type, machine tool type, cutting parameters and other process parameters and methods related to the milling process of the part are set; in the processing simulation module, the blank parameters, processing tool information, machine ...

Embodiment 3

[0042] Embodiment 3: Feature data includes basic information of complex curved surfaces, profile feature data, processing technology feature data, basic information of complex curved surfaces such as: serial number, name, type, etc., profile feature data such as: feature points, feature lines and feature The characteristic parameters of the surface, the degree of curvature change, the outer boundary characteristics, the surface stiffness, etc., and the processing process characteristic data such as: optimal processing method, process parameter information, processing tool information, processing machine tool information, etc.

[0043] The process of establishing the feature database includes the following steps:

[0044] a On the basis of analyzing various types of complex surface features, use feature points, feature lines and feature planes to describe complex surface features;

[0045] b Express the characteristic parameters of characteristic points, characteristic lines an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com