Building cylinder arrangement for a machine for the layer-by-layer production of three-dimensional objects

A three-dimensional object, layer-by-layer manufacturing technology, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of leaky pistons, jamming, etc., and achieve the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

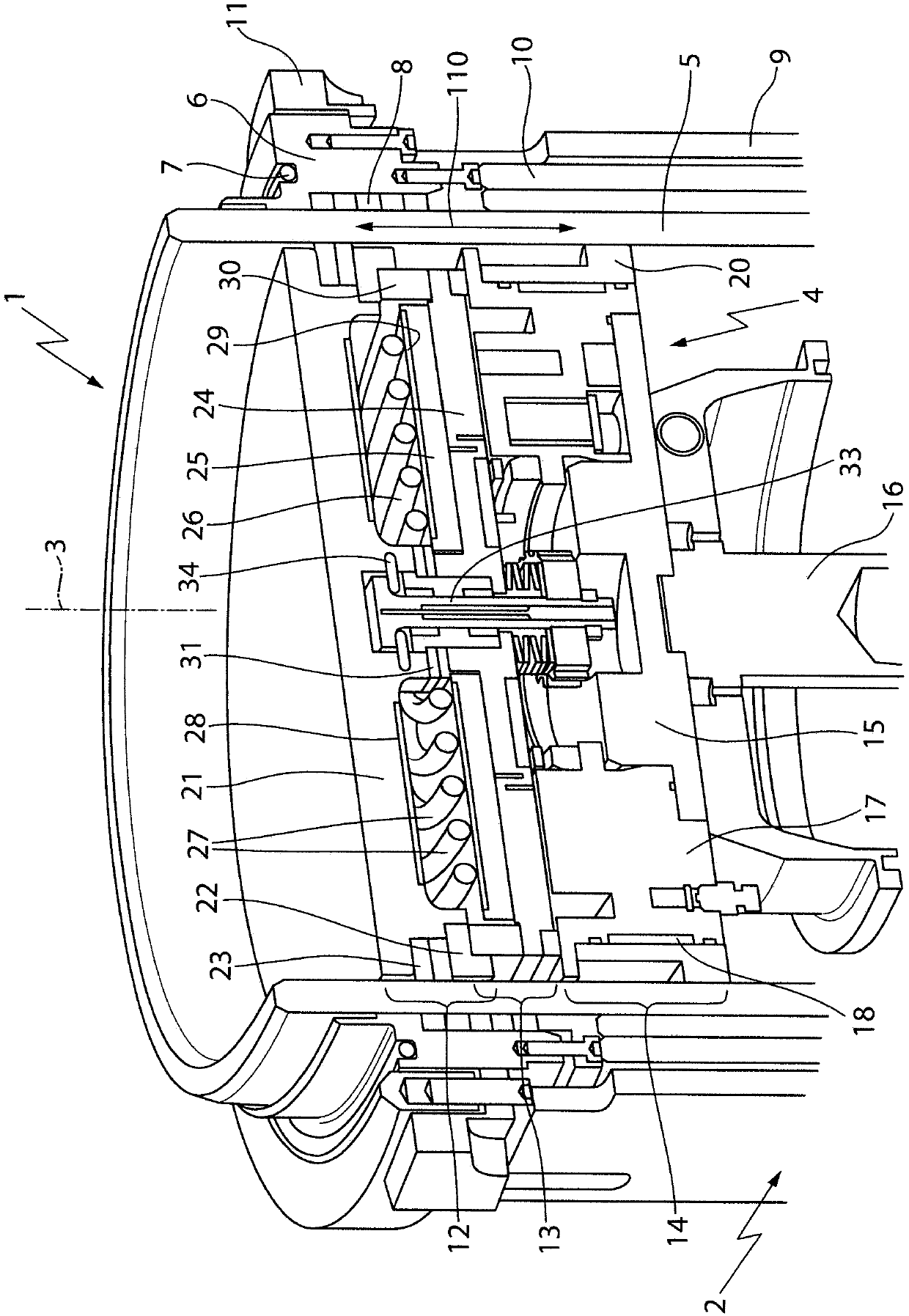

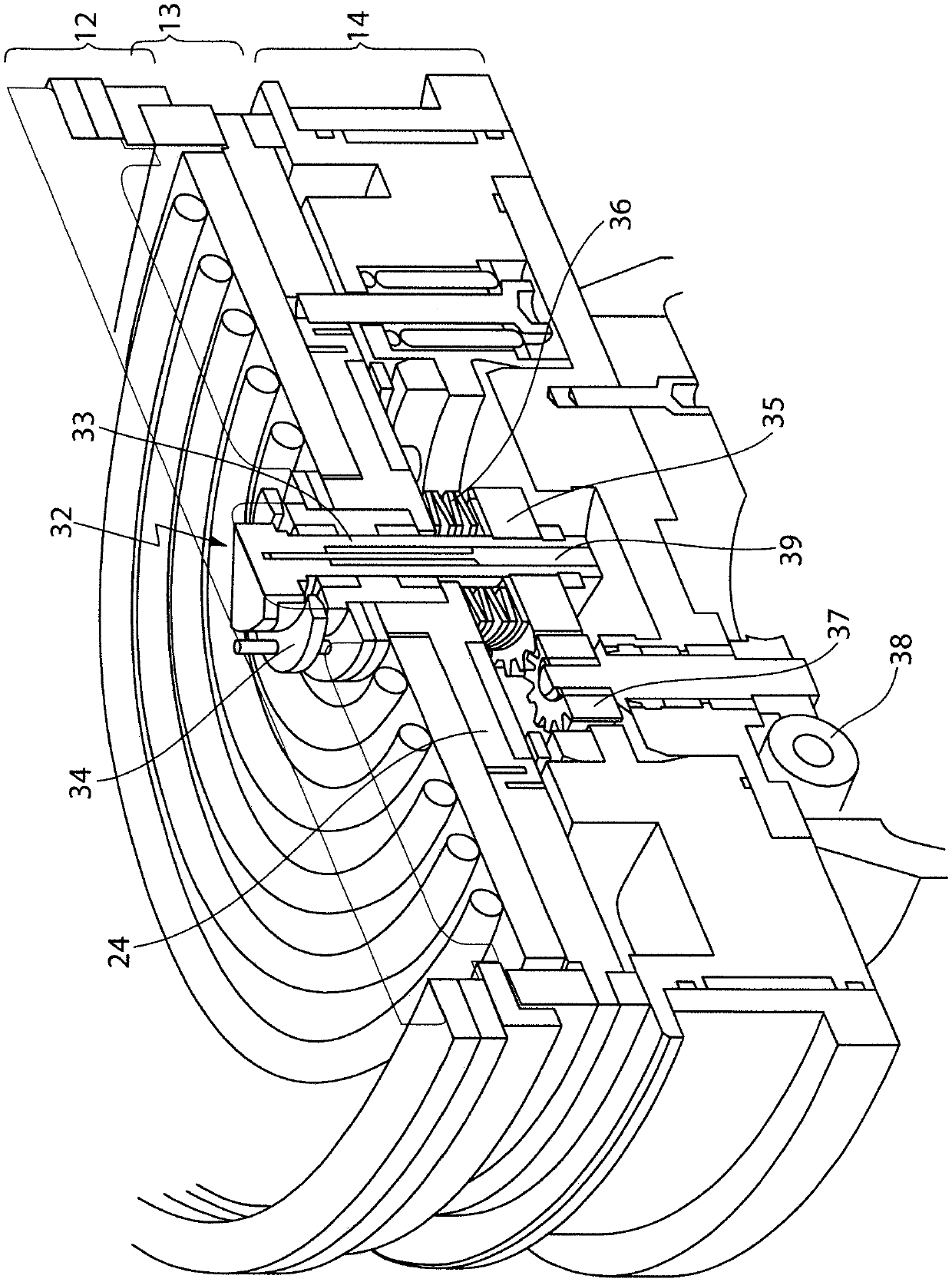

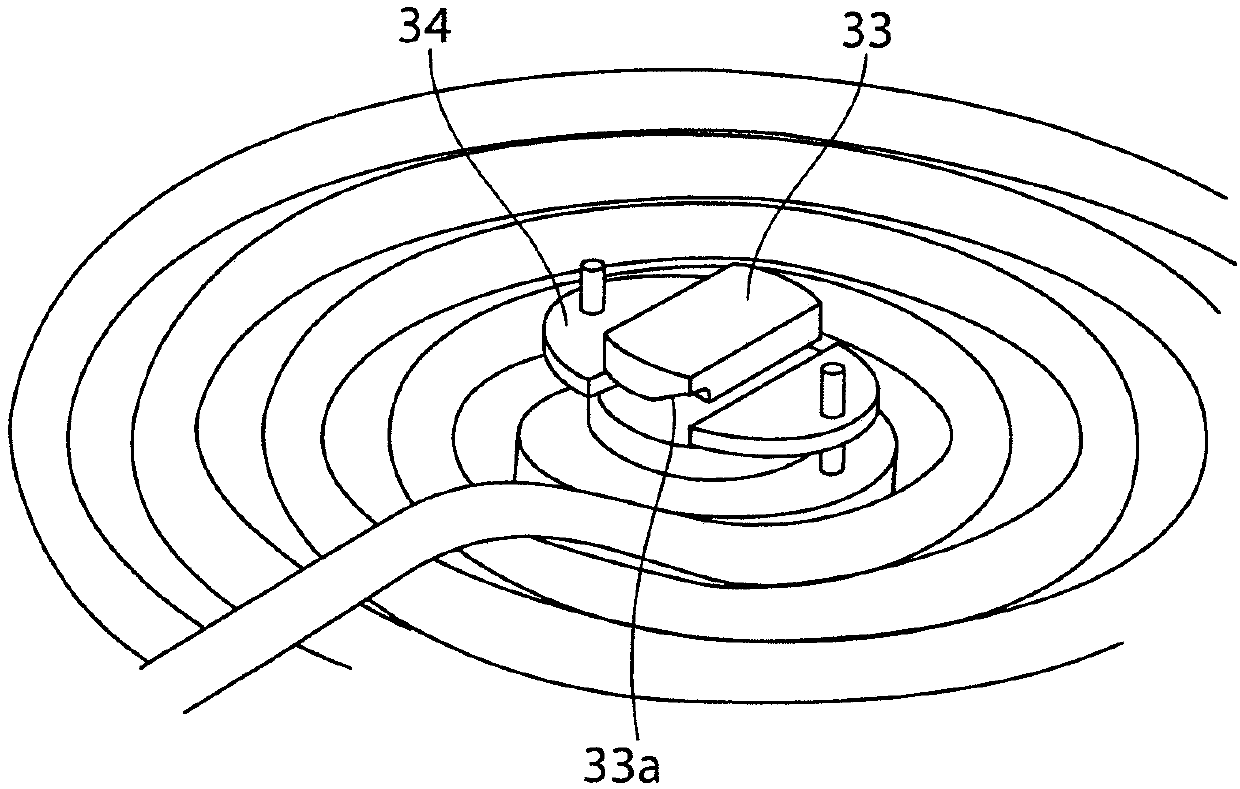

[0071] figure 1 The upper end region of an embodiment of a construction cylinder assembly 1 according to the invention is shown, comprising a substantially cylindrical tubular base body 2 and a piston 4 displaceable in the base body along a cylinder axis 3 .

[0072] The base body 2 is formed on the inside with a cylindrical tubular insulation 5 made of opaque quartz glass. The quartz glass has a thermal conductivity of approximately 2W / (m*K).

[0073] The separator 5 is held by a locking ring 6 configured with cooling water channels 7 and passed through a ceramic fabric (e.g. Al 2 o 3 The packing sleeve 8 made of fabric) clamps the spacer 5. The insulating body 5 is generally surrounded by a cylindrical tubular outer body 9 , which here is constructed of steel. Between the outer body 9 and the insulating body 5 is arranged a thermal insulation 10 , which here is made of a ceramic fiber mat.

[0074] Furthermore, the base body 2 is equipped with hook elements 11 , by mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com