Optical system of a projection exposure equipment for microlithography

An optical system and microlithography technology, applied in the field of optical systems, can solve problems such as damage to the imaging characteristics of projection exposure equipment, deformation, increase in thermal energy input, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

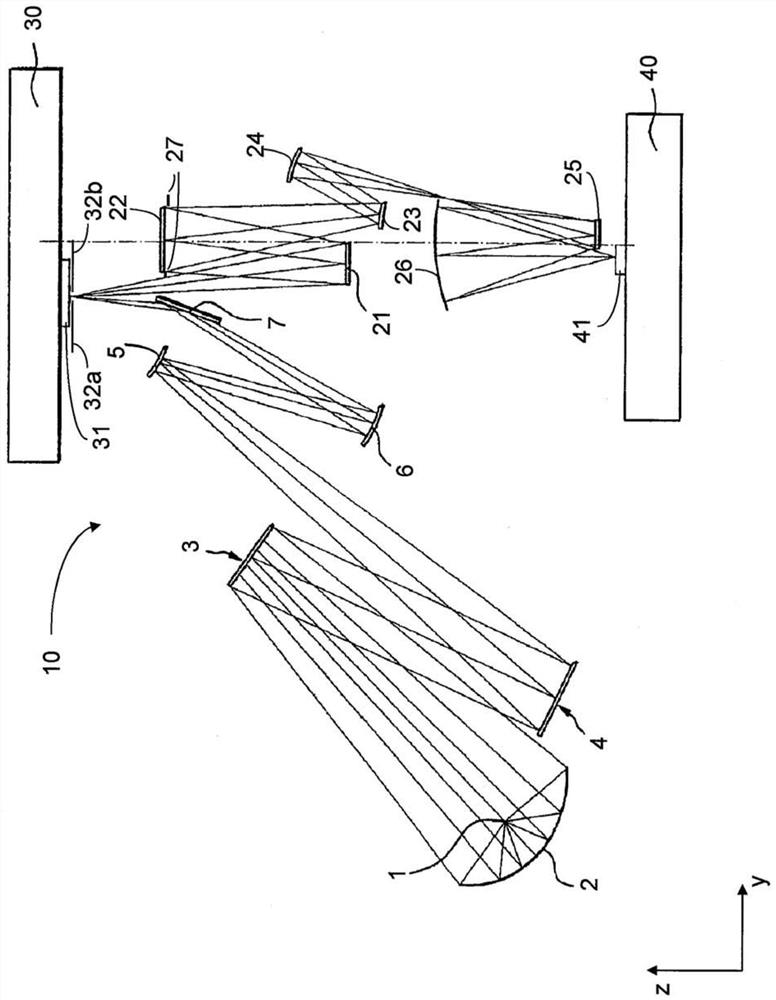

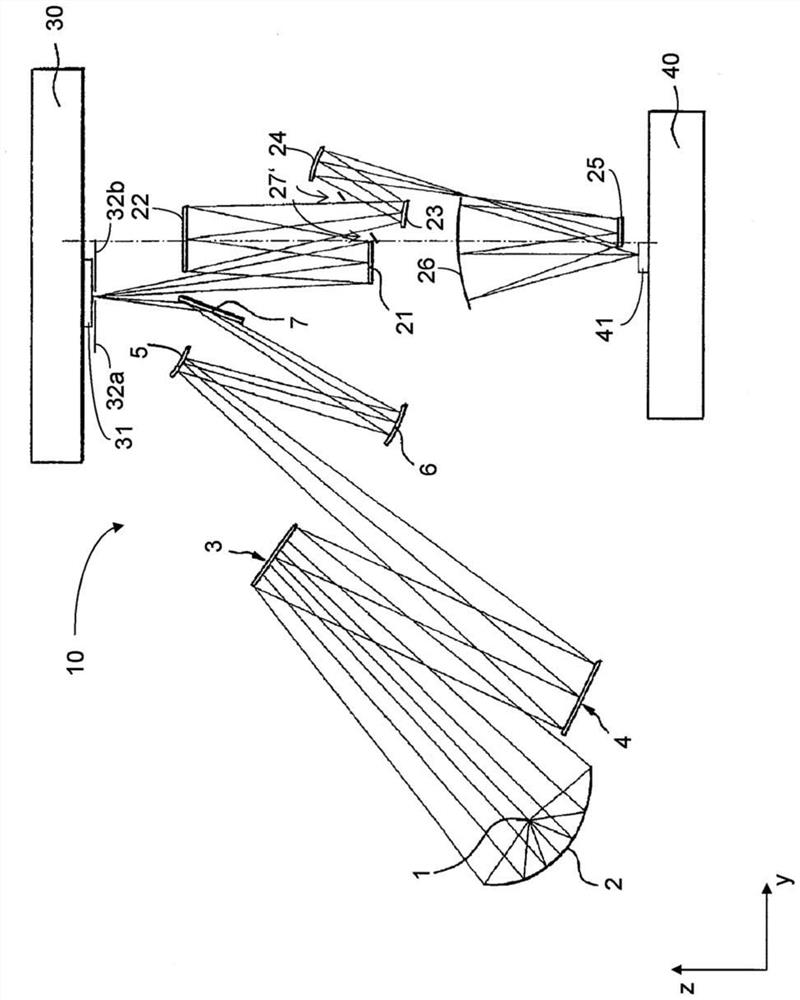

[0038] first, Figure 1a A schematic diagram of a projection exposure apparatus 10 is shown, which is given by way of example and is designed for operation in the EUV range.

[0039] according to Figure 1a, the illumination device of the projection exposure apparatus 10 includes a field facet mirror 3 and a pupil facet mirror 4 . Light comes from a light source unit comprising, for example, a plasma light source 1 and a collector mirror 2 , directing the light onto a field facet mirror 3 . A first telescopic mirror 5 and a second telescopic mirror 6 are arranged in the optical path downstream of the pupil facet mirror 4 . A deflecting mirror 7 is arranged downstream in the beam path, which deflecting mirror directs the radiation incident thereon onto the object field in the object plane of a projection lens comprising six mirrors 21-26. At the position of the object field, a reflective structure-bearing mask 31 is arranged on a mask table 30, said mask being imaged by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com