Cerium-tungsten-tantalum denitration catalyst and preparation method thereof

A denitrification catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as reducing the service life of denitrification catalysts, human health and ecological environment hazards, and easy loss of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A cerium-tungsten-tantalum denitrification catalyst, in which the molar ratio of element cerium, element tungsten, and element tantalum is 2:4:1.

[0055] The preparation method of the above-mentioned cerium-tungsten-tantalum denitration catalyst comprises the following steps:

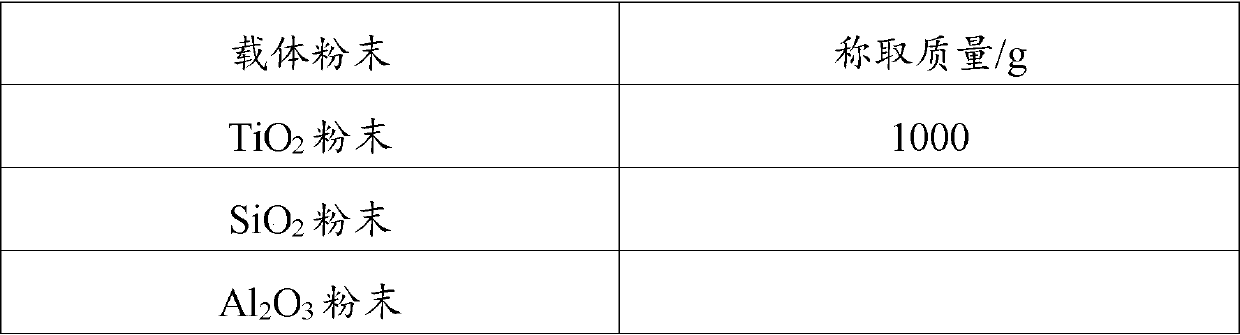

[0056] 1) First, mix and dissolve the cerium source and the tungsten source in water, and let it stand for 6 hours; then add the tantalum source and let it stand for 10 hours to obtain a mixed solution; the sampling of the cerium source, tungsten source, and tantalum source is shown in the following table:

[0057] Ce source

molecular weight

Weighing mass / g

Ce(NO 3 ) 3 ·6H 2 o

434.12

Ce(AC) 3 ·5H 2 o

407.28

Ce 2 (CO 3 ) 3 ·5H 2 o

550.33

550.33

Ce(SO 4 ) 2 4H 2 o

404.30

Ce(OH) 3

191.14

[0058] Tungsten source

molecular weight

Weighing mass / g

(NH 4 ) 5 W...

Embodiment 2

[0071] A cerium-tungsten-tantalum denitrification catalyst, in which the molar ratio of element cerium, element tungsten, and element tantalum is 5:1:4.

[0072] The preparation method of the above-mentioned cerium-tungsten-tantalum denitration catalyst comprises the following steps:

[0073] 1) First mix and dissolve the cerium source and the tungsten source in water, and let it stand for 12 hours; then add the tantalum source and let it stand for 8 hours to obtain a mixed solution; the sampling of the cerium source, tungsten source, and tantalum source is shown in the following table:

[0074] Ce source

molecular weight

Weighing mass / g

Ce(NO 3 ) 3 ·6H 2 o

434.12

434.12

Ce(AC) 3 ·5H 2 o

407.28

407.28

Ce 2 (CO 3 ) 3 ·5H 2 o

550.33

550.33

Ce(SO 4 ) 2 4H 2 o

404.30

404.30

Ce(OH) 3

191.14

[0075] Tungsten source

molecular weight

Weighing mass / g

...

Embodiment 3

[0088] A cerium-tungsten-tantalum denitrification catalyst, in which the molar ratio of element cerium, element tungsten, and element tantalum is 3:2:3.

[0089] The preparation method of the above-mentioned cerium-tungsten-tantalum denitration catalyst comprises the following steps:

[0090] 1) First mix and dissolve the cerium source and the tungsten source in water, and let it stand for 7 hours; then add the tantalum source and let it stand for 11 hours to obtain a mixed solution; the sampling of the cerium source, tungsten source, and tantalum source is shown in the following table:

[0091]

[0092]

[0093]

[0094]

[0095] 2) Adjust the pH of the mixed solution obtained in step 1) with urea solution, so that the pH value reaches 11; heat and stir; the heating temperature is 60° C., and the stirring time is 11 hours.

[0096] 3) Filter the mixed liquid obtained in step 2) to obtain mud; dry the filtered mud at 115° C. for 9 hours to obtain a block; grind the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com