Artificial quartz stone panel and preparation method thereof

An artificial quartz stone and plate technology, which is applied in the field of quartz stone plate manufacturing, can solve problems such as cracking and insufficient toughness, and achieve the effects of ensuring compactness, good curing effect, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

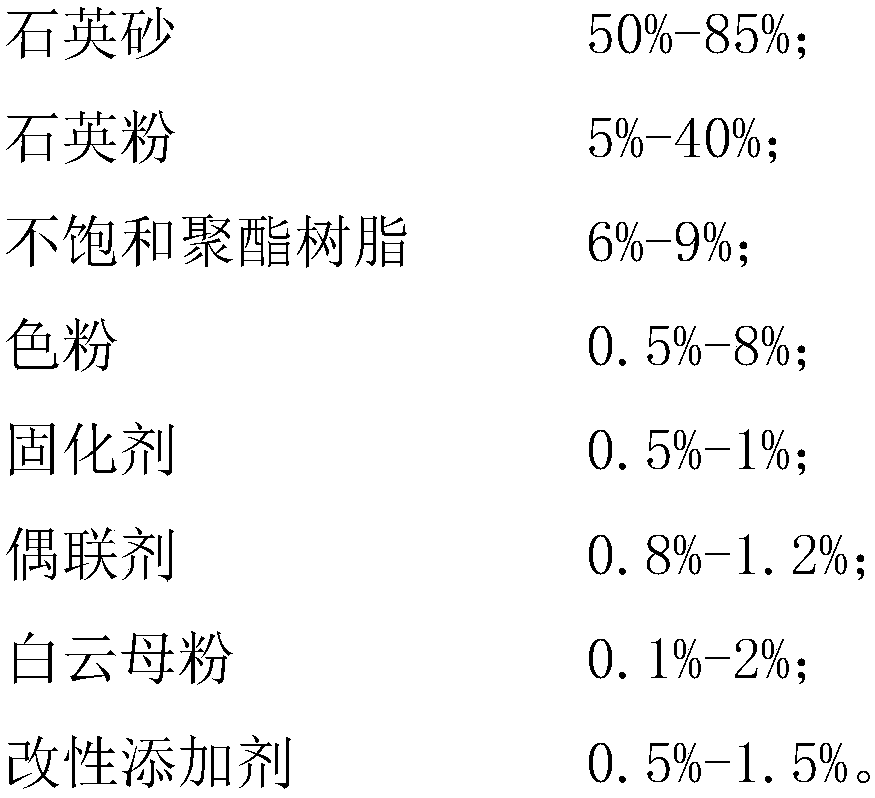

[0026] An artificial quartz stone plate, according to weight percentage, the composition includes:

[0027]

[0028]

[0029] The unsaturated polyester resin includes epoxy resin and polyurethane resin, and the weight ratio of epoxy resin and polyurethane resin is 1:2.

[0030] The curing agent includes methyl ethyl ketone peroxide, tetraethylenepentamine and trimethylhexamethylenediamine, and the weight ratio of methyl ethyl ketone peroxide, tetraethylenepentamine and trimethylhexamethylenediamine is 3:3:4.

[0031] The coupling agent includes 1,2-bistrimethoxysilylethane.

[0032] The modified additive includes calcium carbonate modified by a borate coupling agent.

[0033] A method for preparing artificial quartz stone plates, comprising the steps of:

[0034] (1) Measure each component in proportion;

[0035] (2) Mix 1 / 3 volume of toner and quartz powder for 6-8 hours to obtain system 1;

[0036] (3) mixing system 1 with quartz sand to obtain system 2;

[0037] ...

Embodiment 2

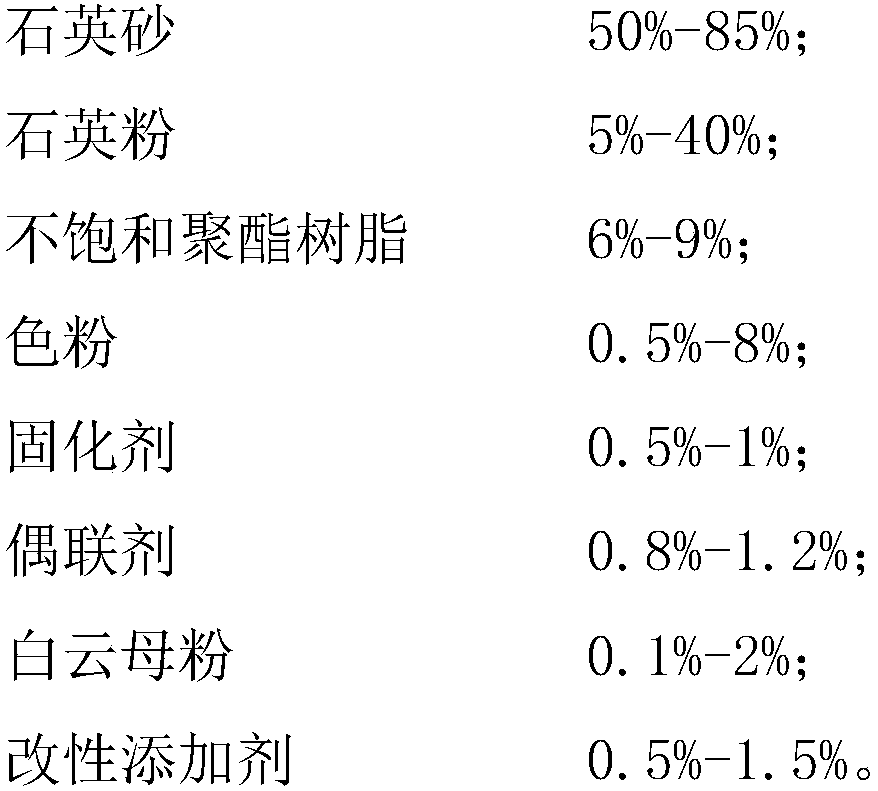

[0045] An artificial quartz stone plate, according to weight percentage, the composition includes:

[0046]

[0047] The unsaturated polyester resin includes epoxy resin and polyurethane resin, and the weight ratio of epoxy resin and polyurethane resin is 1:4.

[0048] The curing agent includes methyl ethyl ketone peroxide, tetraethylenepentamine and trimethylhexamethylenediamine, and the weight ratio of methyl ethyl ketone peroxide, tetraethylenepentamine and trimethylhexamethylenediamine is 3:3:4.

[0049] The coupling agent includes 1,2-bistrimethoxysilylethane.

[0050] The modified additives include calcium carbonate modified by a borate coupling agent and borate whiskers modified by a borate coupling agent.

[0051] A method for preparing artificial quartz stone plates, comprising the steps of:

[0052] (1) Measure each component in proportion;

[0053] (2) Mix 1 / 3 volume of toner and quartz powder for 8 hours to obtain system 1;

[0054] (3) mixing system 1 with ...

Embodiment 3

[0063] An artificial quartz stone plate, according to weight percentage, the composition includes:

[0064]

[0065] Further, the unsaturated polyester resin includes epoxy resin and polyurethane resin, and the weight ratio of epoxy resin and polyurethane resin is 1:2.

[0066] Further, the curing agent includes methyl ethyl ketone peroxide, tetraethylenepentamine, and trimethylhexamethylenediamine, and the weight ratio of methyl ethyl ketone peroxide, tetraethylenepentamine, and trimethylhexamethylenediamine is 3:3:4.

[0067] Further, the coupling agent includes 1,2-bistrimethoxysilylethane.

[0068] Further, the modified additives include calcium carbonate modified by a borate coupling agent, and borate whiskers modified by a borate coupling agent.

[0069] A method for preparing artificial quartz stone plates, comprising the steps of:

[0070] (1) Measure each component in proportion;

[0071] (2) Mix 1 / 4 volume with quartz powder for 8 hours to obtain system 1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com