Antibacterial coating for internal wall

An antibacterial coating and interior wall technology, applied in the field of coatings, can solve the problems of unsuitable coatings and environmental health, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

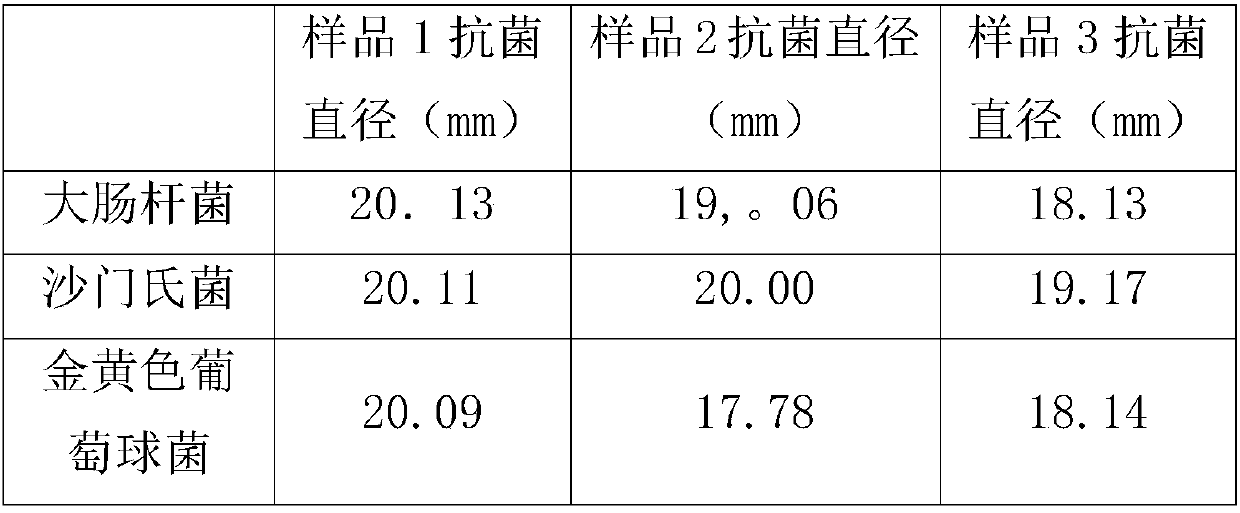

Examples

Embodiment 1

[0012] Weigh 28 parts by mass of aluminate cement, 25 parts by mass of sodium phosphate, 7 parts by mass of magnesium oxide, 8 parts by mass of aluminum oxide, 7 parts by mass of titanium dioxide, 9 parts by mass of sodium lauryl sulfate, 11 parts by mass of bentonite, diphosphate Add 8 parts by mass of lithium hydrogen aerosol to 55 parts by mass of ethanol and mix uniformly, then add 15 parts by mass of chitosan and stir until uniformly mixed to prepare a coating sample of the present invention.

Embodiment 2

[0014] Weigh 19 parts by mass of aluminate cement, 28 parts by mass of sodium phosphate, 5 parts by mass of magnesium oxide, 10 parts by mass of aluminum oxide, 4 parts by mass of titanium dioxide, 11 parts by mass of sodium lauryl sulfate, 9 parts by mass of bentonite, diphosphate Add 55 parts by mass of ethanol to 11 parts by mass of lithium hydrogen aerosol and mix uniformly, then add 15 parts by mass of lithium carbonate and stir until uniformly mixed to obtain a coating sample of the present invention.

Embodiment 3

[0016] Weigh 29 parts by mass of aluminate cement, 21 parts by mass of sodium phosphate, 9 parts by mass of magnesium oxide, 6 parts by mass of alumina, 8 parts by mass of titanium dioxide, 6 parts by mass of sodium lauryl sulfate, 13 parts by mass of bentonite, diphosphate Add 7 parts by mass of lithium hydrogen aerosol to 55 parts by mass of ethanol and mix uniformly, then add 15 parts by mass of sodium benzoate and stir until uniformly mixed to obtain a coating sample of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com