Aviation interior decoration thin-film composite material and method for preparing same

A thin-film composite material and interior decoration technology, which is applied in chemical instruments and methods, synthetic resin layered products, non-polymer organic compound adhesives, etc., can solve the problems of poor thermal insulation effect, heavy quality, and low strength, and achieve Good flame retardant performance, high yield rate, and low surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

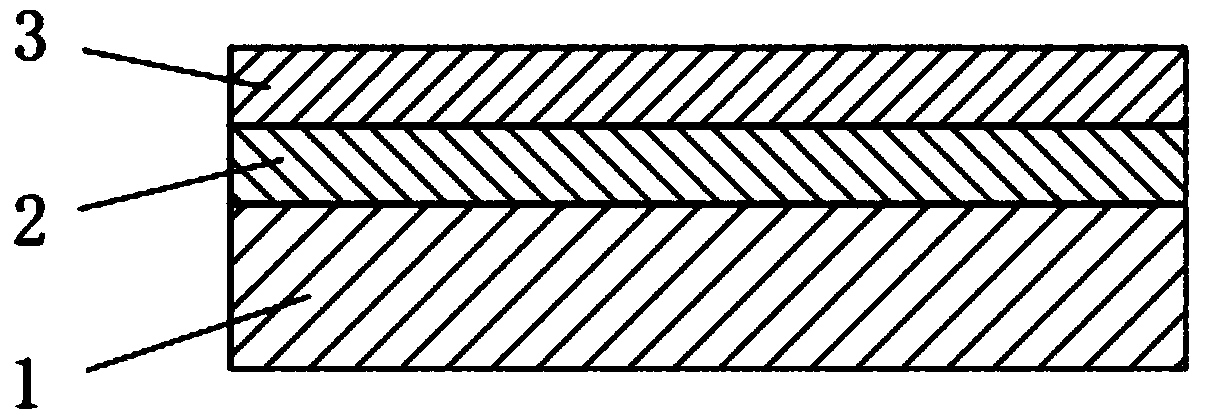

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 As shown, a film composite material for aviation interior decoration according to the present invention includes a material layer 1, an aluminum foil layer 2 and a grid layer 3, and the material of the material layer 1 is one or more of PVDF, PVF or PEEK The thickness of material layer 1 is 18-25 microns, the grid layer 3 is nylon 66 fiber, nylon 66 fiber plain weave or cross weave, the distance between every two fibers is 2-3.5mm, the thickness of aluminum foil layer 2 is 6.5 -12 microns; the material layer 1 is arranged on one side of the aluminum foil layer 2 , and the grid layer 3 is laid on the other side of the aluminum foil layer 2 .

[0014] The preparation method of the above-mentioned thin film composite material for aviation interior decoration includes the following process: subjecting the material layer 1 to corona treatment; plain weaving or cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com