Cycloalkyl heavy traffic asphalt modification stabilizer

A heavy-duty asphalt and stabilizer technology, applied in the field of SBS modified asphalt, can solve the problems of performance degradation, high temperature viscosity, etc., and achieve the effect of improving high and low temperature performance and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

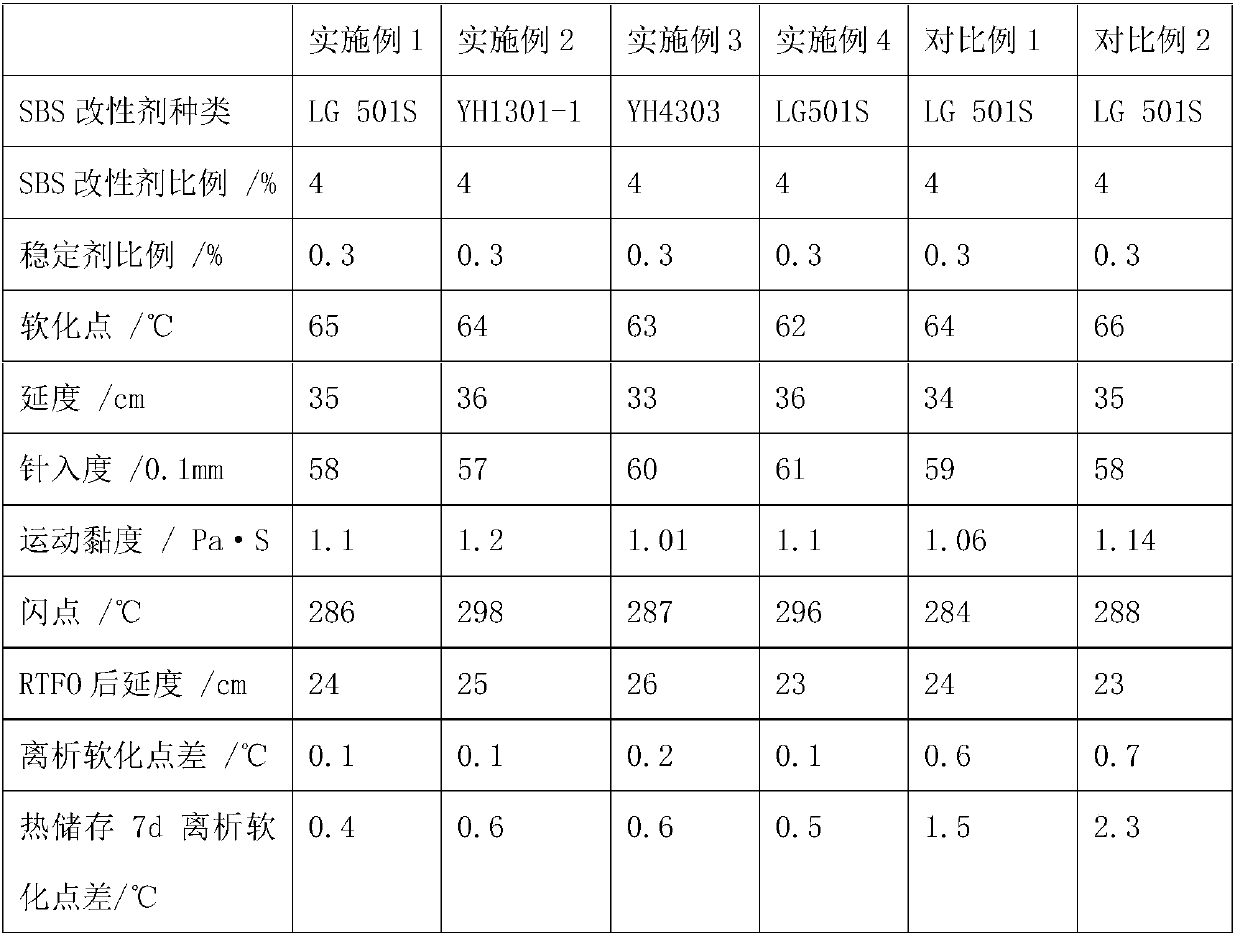

Examples

Embodiment 1

[0035] 1 preparation

[0036] 35 parts by weight of crosslinking agent, 10 parts by weight of accelerator, 10 parts by weight of activator, 15 parts by weight of inorganic soil, 30 parts by weight of viscosity modifier;

[0037]Among them, the crosslinking agent is powdered sulfur with a content of 99%, sodium sulfide, and sodium petroleum sulfonate mixed in a mass ratio of 1:0.35:0.8, and the accelerator is commercial tetrabenzylthiuram disulfide, benzoyl peroxide According to the mixture with a mass ratio of 1:1, the activator is commercial stearic acid, the inorganic soil is commercial diatomaceous earth, and the viscosity modifier is Sasobit, produced by Sasol-Wax Company in Germany.

[0038] 2 Preparation of stabilizer

[0039] (1) Mix all the raw materials except the viscosity modifier uniformly at room temperature to obtain the stabilizer basic material;

[0040] (2) Pass the viscosity improver through Tianguan brand GJ type pulverizer, pulverize it into powdery parti...

Embodiment 2

[0044] 1 preparation

[0045] 60 parts by weight of crosslinking agent, 12 parts by weight of accelerator, 10 parts by weight of activator, 8 parts by weight of inorganic soil, 10 parts by weight of viscosity modifier

[0046] Among them, the crosslinking agent is powdered sulfur with a content of 99%, potassium sulfide, calcium petroleum sulfonate mixed according to the mass ratio of 1:0.6:1.5, and the accelerator is commercial ethylphenyl dithiocarbamate zinc, dibenzyl dithiocarbamate A mixture of zinc thiocarbamate and tetrabenzylthiuram disulfide in a ratio of 1:1:1, the activator is commercial zinc oxide, the inorganic soil is commercial montmorillonite, and the viscosity modifier is Sasobit, produced in Germany Sasol -Wax Inc.

[0047] 2 Preparation of stabilizer

[0048] (1) Mix all the raw materials except the viscosity modifier uniformly at room temperature to obtain the stabilizer basic material;

[0049] (2) Pass the viscosity improver through Tianguan brand GJ p...

Embodiment 3

[0053] 1 preparation

[0054] 40 parts by weight of crosslinking agent, 20 parts by weight of accelerator, 10 parts by weight of activator, 10 parts by weight of inorganic soil, 20 parts by weight of viscosity modifier

[0055] Among them, the crosslinking agent is powdered sulfur with a content of 99%, ammonium sulfide, and barium petroleum sulfonate mixed according to the mass ratio of 1:0.5:2.0, and the accelerator is commercial tetrabenzylthiuram disulfide, benzoyl peroxide and A mixture of zinc oxide in a ratio of 1:1:1, the activator is commercial stearic acid, the inorganic soil is commercial nano-bentonite, and the viscosity modifier is Sasobit, produced by Sasol-Wax Company in Germany.

[0056] 2 Preparation of stabilizer

[0057] (1) Mix all the raw materials except the viscosity modifier uniformly at room temperature to obtain the stabilizer basic material;

[0058] (2) Pass the viscosity improver through Tianguan brand GJ pulverizer, pulverize it into powdery par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com