Comprehensive recovery method for cathode materials of ternary lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in the field of comprehensive recovery of positive electrode materials for ternary lithium-ion batteries, can solve the problems of low Li recovery rate and achieve the effect of improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

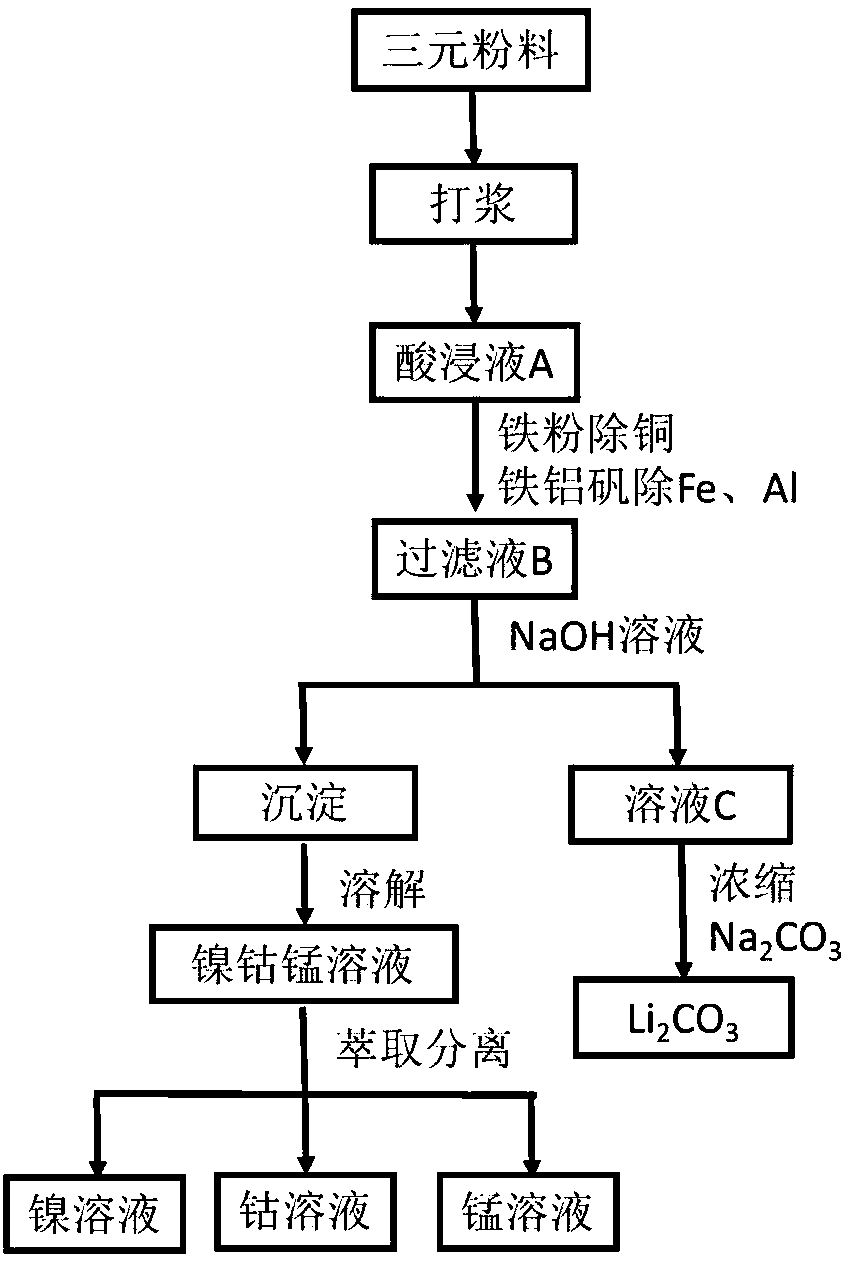

[0025] A comprehensive recovery method for ternary lithium-ion battery cathode materials, comprising the following steps:

[0026] S1. Add the positive electrode powder of the ternary lithium-ion battery into water for beating treatment to obtain a beating liquid. The mass ratio of solid to liquid in the beating liquid is 1:6. Then add concentrated sulfuric acid and hydrogen peroxide and stir for 1.5 hours. The stirring temperature is 70°C. The volume-to-volume ratio (mol / L) of the material to the beating liquid is 2:1, the volume-to-mass ratio (mL / g) of the hydrogen peroxide to the positive electrode powder of the ternary lithium-ion battery is 2:1, and the pickling solution A is obtained by filtration;

[0027] S2, adjust pickling solution A to be acidic, add excessive Fe powder to remove Cu impurity, then use the sender method to remove iron and aluminum impurities in the solution, and filter to obtain filtrate B;

[0028] S3. Adjust the filtrate B to be alkaline to precipi...

Embodiment 2

[0032] A comprehensive recovery method for ternary lithium-ion battery cathode materials, comprising the following steps:

[0033] S1. Add the positive electrode powder of the ternary lithium-ion battery into water for beating treatment to obtain a beating liquid. The mass ratio of solid to liquid in the beating liquid is 1:8. Then add concentrated sulfuric acid and hydrogen peroxide and stir for 2.5 hours. The stirring temperature is 80°C. The volume-to-volume ratio (mol / L) of the material to the beating liquid is 4:1, the volume-to-mass ratio (mL / g) of the hydrogen peroxide to the positive electrode powder of the ternary lithium-ion battery is 3:1, and the pickling solution A is obtained by filtration;

[0034] S2, adjust pickling solution A to be acidic, add excessive Fe powder to remove Cu impurity, then use the sender method to remove iron and aluminum impurities in the solution, and filter to obtain filtrate B;

[0035] S3. Adjust the filtrate B to be alkaline to precipi...

Embodiment 3

[0039] A comprehensive recovery method for ternary lithium-ion battery cathode materials, comprising the following steps:

[0040] S1. Add 1 kg of ternary lithium-ion battery positive electrode powder into 4 L of deionized water for beating treatment to obtain a beating liquid, then add 20 mol of concentrated sulfuric acid and 1 L of hydrogen peroxide and stir for 3 hours at a stirring temperature of 60 ° C, and filter to obtain acid dipping liquid A;

[0041] S2. Adjust the pH value of pickling solution A to 2, add excess Fe powder to remove Cu impurities, then add excess sodium chlorate and sodium carbonate, adjust the pH value to 2.5 to remove iron and aluminum impurities in the solution, and filter to obtain filtered Liquid B;

[0042] S3. Add NaOH solid to the filtrate B, adjust the pH value of the filtrate B to 10 to precipitate nickel, cobalt, and manganese elements, and filter to obtain solution C and filter residue D;

[0043] S4. Concentrate the solution C until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com