Low-grade scrap copper cleaning and smelting new process and device thereof

A waste copper, low-grade technology, applied in the field of copper smelting, can solve the problems of difficult energy saving, environmental protection problems, large loss of refractory materials, etc., to avoid dioxin production, improve environmental protection conditions and life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

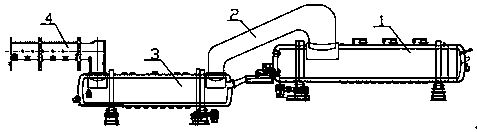

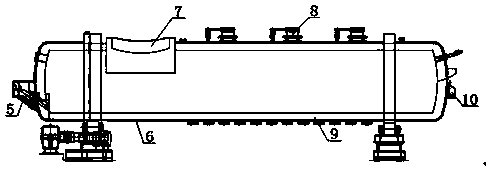

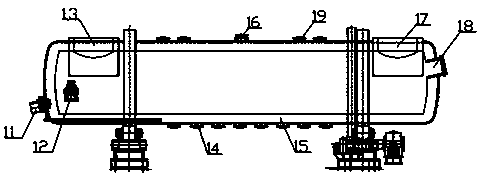

[0030] A new clean smelting process of low-grade miscellaneous copper and its device, the device includes a bottom-blown melting furnace 1, a connecting flue 2, a bottom-blown redox furnace 3 and a secondary combustion chamber 4; the bottom-blown melting furnace 1 The furnace body is a cylindrical horizontal rotary smelting furnace lined with refractory brick A9. One end of the top end of the furnace body is a scrap copper feeding port 8, the other end of the top is provided with a flue port A7, and the bottom of the furnace body is equipped with a spray gun below the flue port A7. Port A6, the side of the flue port A7 one end of the furnace body is connected to the copper discharge port device A5, and the other end is provided with the slag discharge port device A10; the furnace body of the bottom blowing redox furnace 3 is a cylindrical horizontal rotary smelting furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com