Feed pipe for conveying automobile gas

A feeding pipe and gas technology, which is applied in the direction of charging systems, combustion engines, internal combustion piston engines, etc., can solve the problems of large engine noise, loud noise, and high pressure of feeding pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

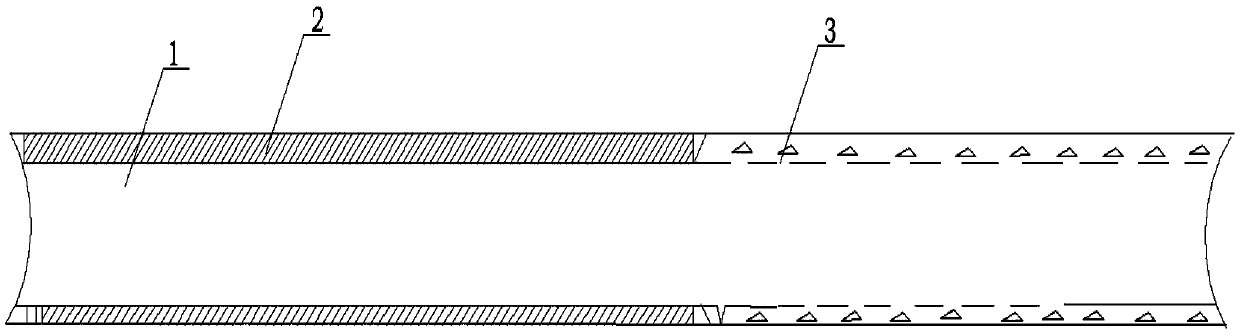

[0023] Such as figure 1 , figure 2 As shown, a feed pipe for automobile gas transportation includes a pipe main body 1 and a pipe main body 1 . The inner side of the pipe is covered with sound-absorbing cotton 2 and sound-absorbing material layer 3 , and the sound-absorbing cotton 2 and sound-absorbing material layer 3 are alternately distributed on the inner side of the pipe main body 1 .

[0024] Preferably, the sound-absorbing cotton 2 is glass fiber sound-absorbing cotton used in the gas pipeline.

[0025] Preferably, the sound-absorbing cotton 2 is prepared from quartz sand, limestone and dolomite as raw materials.

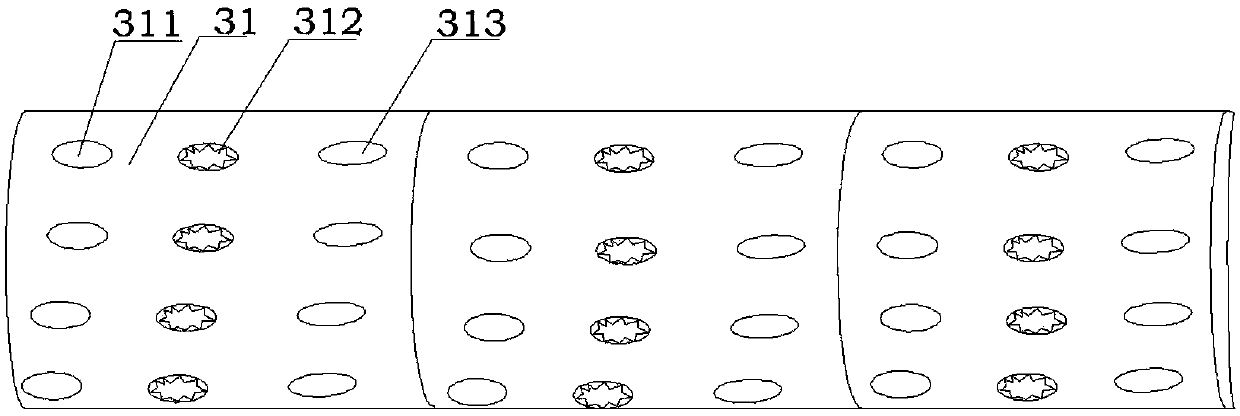

[0026] Preferably, the sound-absorbing material layer 3 is provided with micropores 311, mesopores 312, and macropores 313, and the micropores 311, mesopores 312, and macropores 313 form a group of porous structures, and the micropores 311, mesopores The spacing between the holes 312 and the large holes 313 is equal, and there are multiple groups of hole-...

Embodiment 2

[0029] This embodiment is further preferred on the basis of the embodiment, the pore diameter of the micropore 311 is 1 nm, the pore diameter of the mesopore 312 is 3 nm, and the pore diameter of the macropore 313 is 55 nm.

Embodiment 3

[0031] This embodiment is further preferred on the basis of the embodiment, the pore diameter of the micropore 311 is 0.5 nm, the pore diameter of the mesopore 312 is 10 nm, and the pore diameter of the macropore 313 is 100 nm.

[0032] In this embodiment, the sound-absorbing structure of the feed pipe is optimized, wherein the sound-absorbing cotton is a kind of man-made inorganic fiber prepared from quartz sand, limestone, and dolomite as raw materials. In the melted state, it is blown by external force to form floc fine fibers, and the fibers intersect three-dimensionally and intertwine with each other, showing many small gaps.

[0033] In Examples 1-3, through the setting of macropores, mesopores, and micropores in the sound-absorbing material layer, when the sound of gas transmission enters the surface of the component material, part of the sound energy is reflected, part of it penetrates the material, and part of the component material When the vibration or sound propaga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com