A kind of sound-absorbing material and its preparation method and application

A technology of sound-absorbing material and mixed liquid, applied in the field of sound-absorbing material, can solve the problems of no adhesion of structure, poor sound-absorbing effect, low flame retardant performance, etc., and achieve the effect of improving quality, convenient construction and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

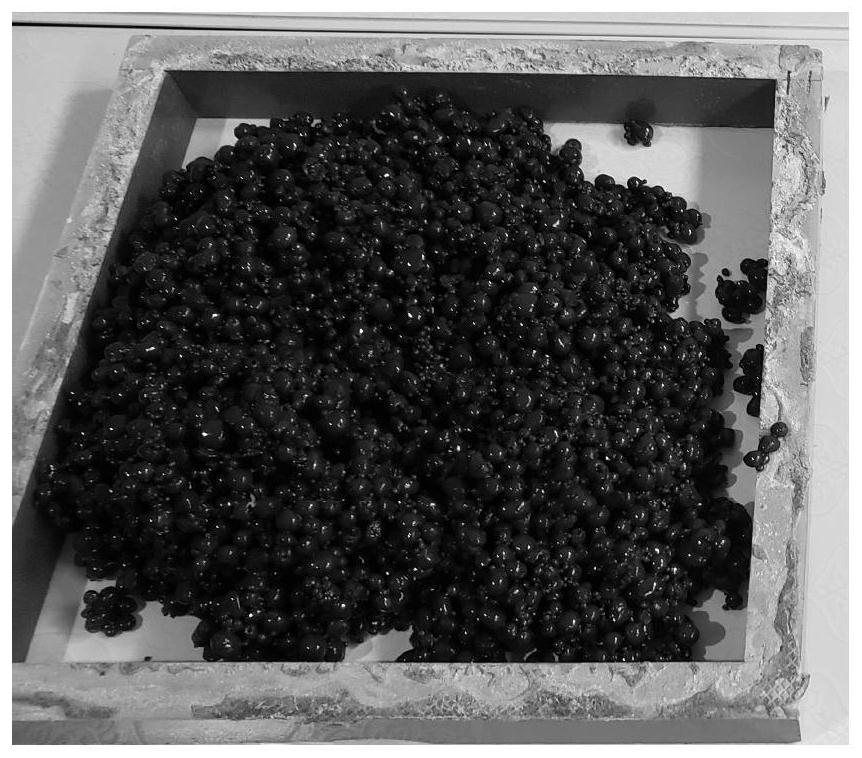

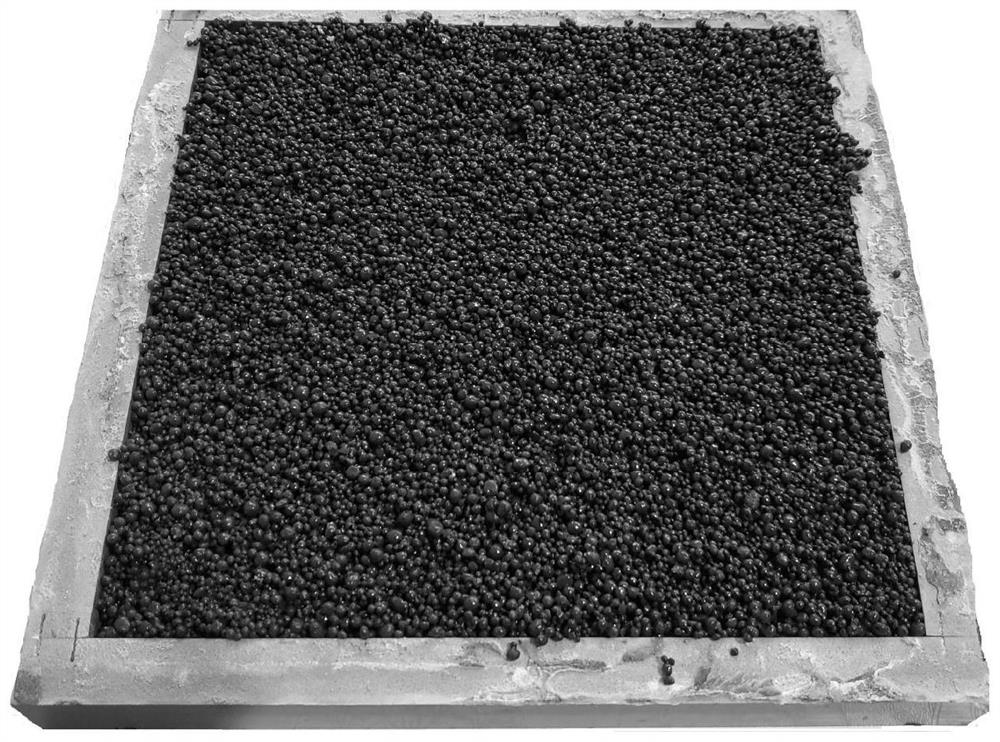

Image

Examples

Embodiment 1

[0071] The sound-absorbing material of the present embodiment is prepared from the following material:

[0072] Microporous ceramics: Microporous ceramics of different particle sizes are used and mixed in different proportions (as shown in Table 1).

[0073]Modified epoxy resin: 1.84kg, titanium dioxide: 3.22kg, inorganic silicon: 2.88kg, flame retardant: 2.54kg, zirconia: 3kg, water-based silica sol: 3.2kg, ethanol: 3.32kg.

[0074] Curing agent: 2.4kg.

[0075] i) put the flame retardant 2.54kg and the inorganic silicon 2.88kg into the reaction tank in turn, heat it to 175 °C, stir for 20 minutes, cool to 26 °C, to obtain the first mixture;

[0076] ii) to step i) to the first mixture obtained by adding titanium dioxide 3.22kg, aqueous silica sol 3.2kg, zirconia 3kg, modified epoxy resin 1.84kg stirred evenly, to give the 2nd mixture;

[0077] iii) The second mixture obtained in step ii) was ground twice by a stick pin sand mill, and then 3.32 kg of ethanol was added and stirred...

Embodiment 2

[0084] Example 2: Screening test for preparing a mixture of sound-absorbing material C

[0085] Using the weight percentage of the raw material shown in Table 2, 7 mixtures C are configured by the following method:

[0086] i) the flame retardant and inorganic silicon are successively put into the reaction tank, heated to 175 ° C, stirred for 20 minutes, cooled to 26 ° C, to obtain the first mixture;

[0087] ii) to step i) the resulting mixture of titanium dioxide, aqueous silica sol, zirconium dioxide, modified epoxy resin stirred evenly, to give the second mixture;

[0088] iii) the second mixture obtained in step ii) was ground twice by a rod pin sand mill, and then ethanol was added and stirred for 20 minutes to give the mixture C.

[0089] The viscosity, adhesion and impact strength of the obtained mixture C sample 1, 2, 3, 4, 5, 6 and 7 are determined, and the determination method is as follows: The determination of dynamic viscosity is carried out in accordance with GB / T97...

Embodiment 3

[0102] Example 3: The effect of temperature on the final sound-absorbing material

[0103] i) Put the flame retardant and the inorganic silicon into the reaction tank in turn and heat it to T 31 , stir for 20 minutes, cool to 26 ° C, to give the first mixture;

[0104] ii) to step i) the resulting mixture of titanium dioxide, aqueous silica sol, zirconium dioxide, modified epoxy resin stirred evenly, to give the second mixture;

[0105]iii) the second mixture obtained in step ii) was ground twice by a rod pin sand mill, and then ethanol was added and stirred for 20 minutes to give the mixture C.

[0106] The different Ts shown by Table 5 below 31 The preparation of the mixture C, according to the method described in Example 1, wherein the use of microporous ceramic particles with a particle size of 4mm and 3mm, a weight ratio of 7:3 to prepare the corresponding sound-absorbing plates, and then determine the sound-absorbing effect of each sound-absorbing plate.

[0107] Table 5:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com