Making method of dried freshwater fish

A production method and technology for freshwater fish, applied in the field of food processing, can solve the problem of high cost, and achieve the effects of low cost, unique flavor and convenient eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

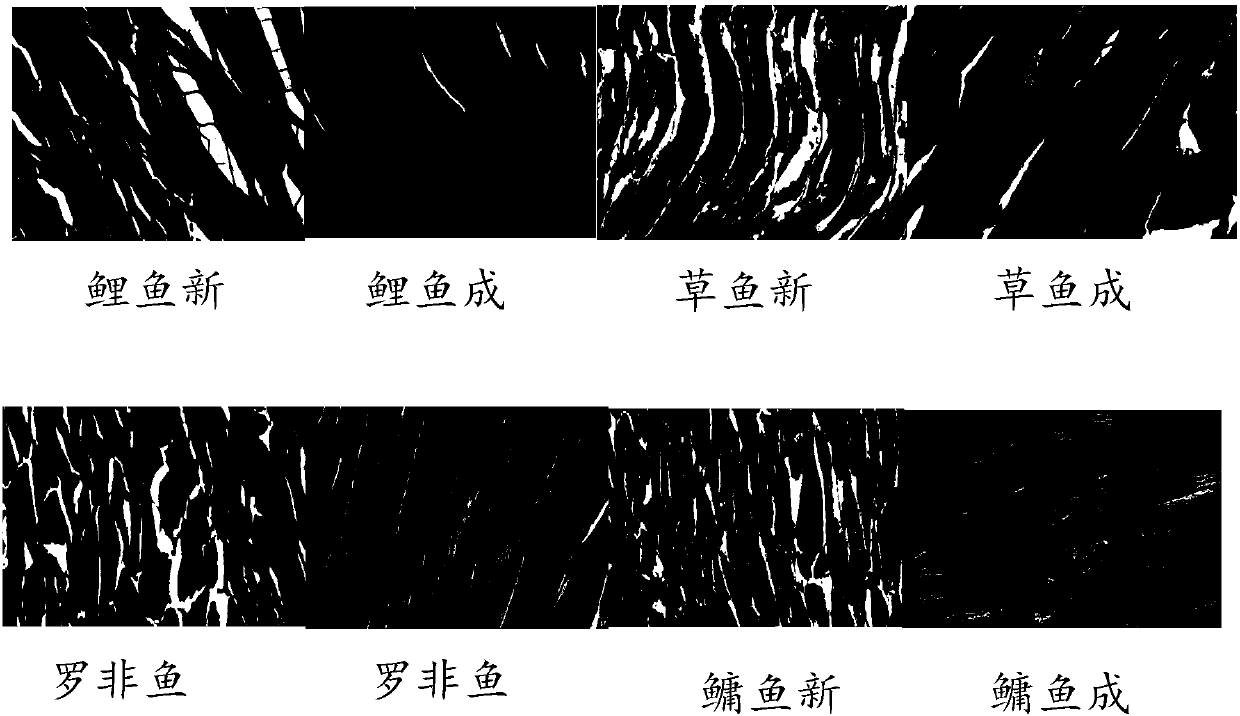

Method used

Image

Examples

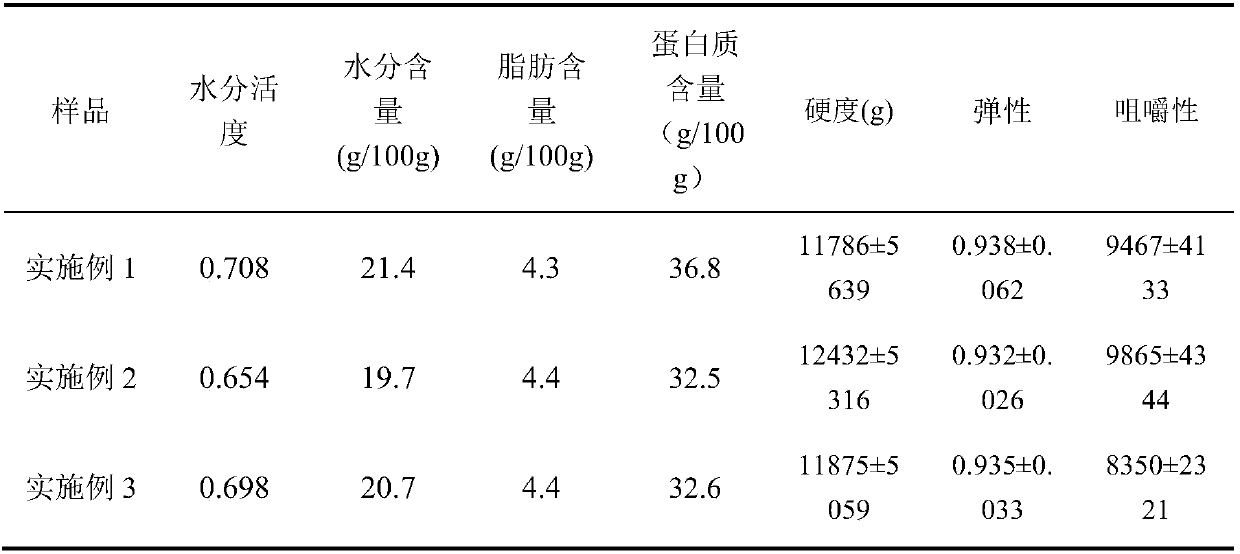

Embodiment 1

[0032] After the grass carp is stunned and slaughtered, remove the fish head, viscera and scales, wash the fish body, remove the backbone, take the meat, cut the fish pieces into 12cm×10cm×2cm pieces, put the fish pieces into a steamer, heat them with steam for 10 minutes, and peel off the fish flesh , remove the fishbone in the fish meat, take cooked 30g grass carp meat, 70g silver carp surimi, 5g soy sauce, 10g rice wine and premixed 10g white sugar, 4g soybean protein isolate, 0.3g compound phosphate, 0.05g white pepper Mix the powder well, spread the mixture into slices with a thickness of 2mm~3mm, compact them, steam them for 10 minutes, take them out, cut them into slices of 4cm*7cm, put them in a microwave oven, dry them at 350W for 7min, and put them in Dry in a hot air drying oven at 70°C for 35 minutes, put it in an oven, and bake at 140°C for 3 minutes. After cooling the dried fish, pack it in vacuum to obtain the finished product. Measure the water activity with a ...

Embodiment 2

[0034] After the grass carp is stunned and slaughtered, remove the fish head, viscera and scales, wash the fish body, remove the backbone, take the meat, cut the fish pieces into 12cm×10cm×2cm pieces, put the fish pieces into a steamer, heat them with steam for 10 minutes, and peel off the fish flesh , remove the fishbone in the fish meat, take cooked 30g grass carp meat, 70g silver carp surimi, 5g soy sauce, 10g rice wine and premixed 10g white sugar, 4g soybean protein isolate, 0.3g compound phosphate, 0.05g white pepper Mix the powder well, spread the mixture into slices with a thickness of 2mm~3mm, compact them, steam them for 10 minutes, take them out, cut them into slices of 4cm*7cm, put them in a microwave oven, dry them at 560W for 5min, and put them in Dry it in a hot air drying oven at 70°C for 45 minutes, put it in an oven, and bake it at 140°C for 3 minutes. After cooling the preserved fish, pack it in vacuum to get the finished product. Measure the water activity ...

Embodiment 3

[0036] After the grass carp is stunned and slaughtered, remove the fish head, viscera and scales, wash the fish body, remove the backbone, take the meat, cut the fish pieces into 12cm×10cm×2cm pieces, put the fish pieces into a steamer, heat them with steam for 10 minutes, and peel off the fish flesh , remove the fishbone in the fish meat, take cooked 30g grass carp meat, 70g silver carp surimi, 5g soy sauce, 10g rice wine and premixed 10g white sugar, 4g soybean protein isolate, 0.3g compound phosphate, 0.05g white pepper Mix the powder well, spread the mixture into slices with a thickness of 2mm~3mm, compact them, steam them for 10 minutes, take them out, cut them into slices of 4cm*7cm, put them in a microwave oven, dry them at 560W for 5min, and put them in Dry in a hot air drying oven at 60°C for 60 minutes, put it in an oven, and bake at 140°C for 3 minutes. After cooling the dried fish, pack it in vacuum to obtain the finished product. Measure the water activity with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com