MnY catalyst for catalytically removing indoor formaldehyde and preparation method thereof

A catalyst and catalyst carrier technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low absorption efficiency, poor absorption effect, high degradation cost, etc., and achieve improved catalytic activity and good catalytic performance , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

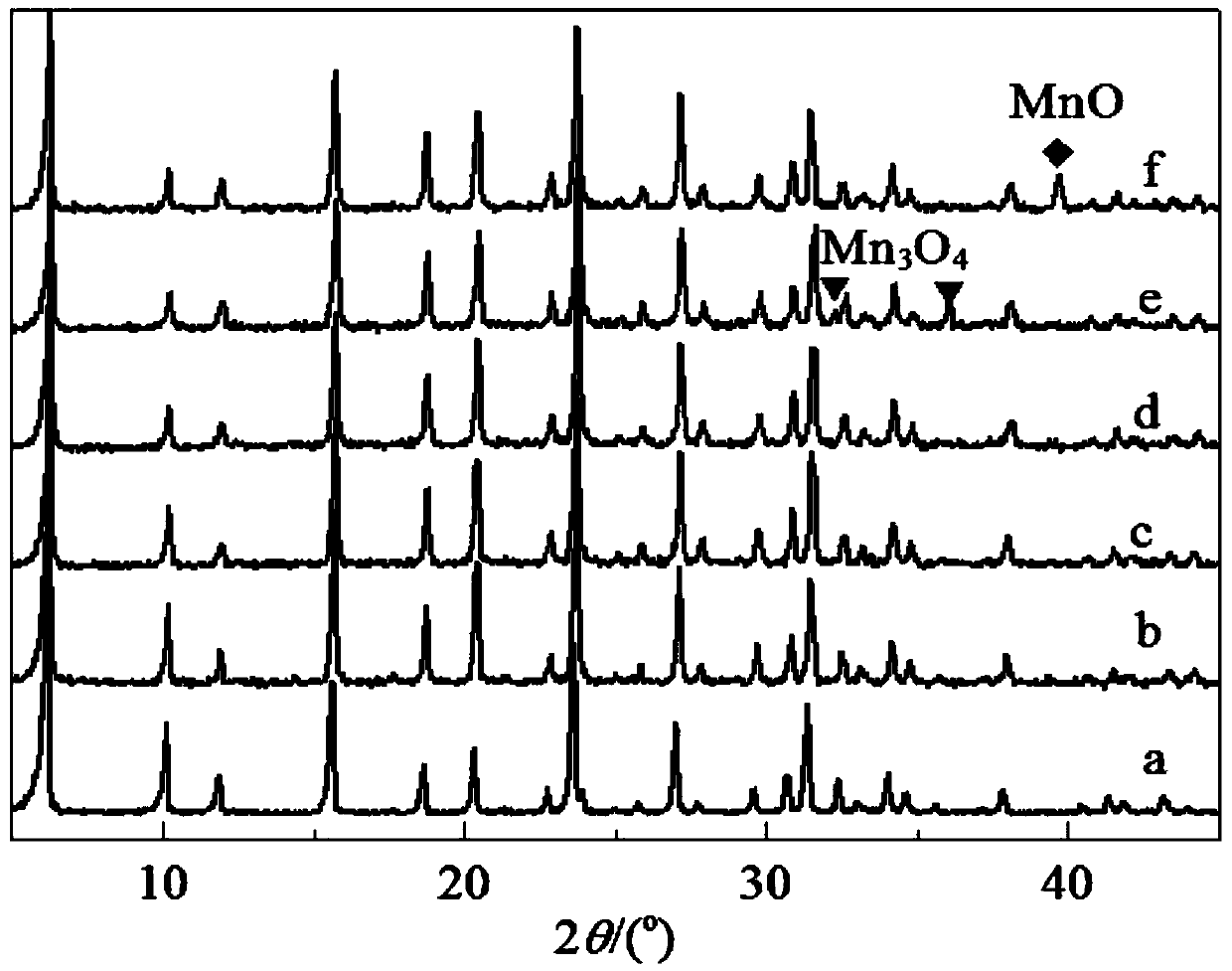

[0031] (1) Weigh 5gNaY molecular sieve (SiO 2 / Al 2 o 3 =4.8, aperture The porosity is 50%) impregnated in 50 mL of acetone solution containing 1.4 g of manganese (II) acetylacetonate, and the manganese (II) acetylacetonate is uniformly adsorbed on Y molecular sieves and stirred at 25 ° C until the acetone solvent is completely volatilized to obtain a catalyst precursor;

[0032] (2) In the air, carry out temperature-programmed activation. The temperature-raising program is to increase the temperature at a rate of 3°C / min to 400°C, and activate at a constant temperature for 4 hours, so that manganese (II) acetylacetonate can decompose on NaY, forming a catalyst for the removal of formaldehyde. The active center-manganese oxide was then naturally cooled to room temperature and taken out to obtain a catalyst. In terms of metal, the loading of Mn was 6.1wt%.

[0033] Catalyst catalytic removal of formaldehyde in indoor air Reaction conditions and specific steps for evaluation...

Embodiment 2

[0036] (1) Weigh 5gNaY molecular sieve (SiO 2 / Al 2 o 3 =5.0, aperture Porosity 50%) impregnated in 50mL acetone solution containing 1.9g manganese (II) acetylacetonate, stirred at 35°C until the acetone solvent volatilized completely, and manganese (II) acetylacetonate was evenly adsorbed on Y molecular sieves to obtain the catalyst precursor ;

[0037] (2) In the air, the temperature-programmed activation is carried out. The temperature-raising program is to increase the temperature at a rate of 3°C / min to 450°C, and activate at a constant temperature for 4 hours, so that manganese (II) acetylacetonate can decompose on NaY, forming a catalyst for the removal of formaldehyde. The active center-manganese oxide was then naturally cooled to room temperature and taken out to obtain a catalyst. In terms of metal, the loading of Mn was 8.2wt%.

[0038] Catalyst catalytic removal of formaldehyde in indoor air Reaction conditions and specific steps for evaluation of adsorption cap...

Embodiment 3

[0041] (1) Weigh 5gNaY molecular sieve (SiO 2 / Al 2 o 3 =5.3, aperture porosity 50%) impregnated in 50mL of acetone solution containing 2.58g manganese (II) acetylacetonate, stirred at 30°C until the acetone solvent volatilized completely, and manganese (II) acetylacetonate was evenly adsorbed on Y molecular sieves to obtain the catalyst precursor ;

[0042] (2) In the air, the temperature program activation is carried out. The temperature increase program is to increase the temperature at a rate of 5 °C / min to 500 °C, and activate at a constant temperature for 3 hours, so that manganese (II) acetylacetonate can decompose on NaY, forming a catalyst for the removal of formaldehyde The active center-manganese oxide was then naturally cooled to room temperature and taken out to obtain a catalyst. In terms of metal, the loading of Mn was 11.4wt%.

[0043] Catalyst catalytic removal of formaldehyde in indoor air Reaction conditions and specific steps for evaluation of adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com