Method for analyzing aroma components in tobacco

An analysis method and technology of aroma components, applied in the field of tobacco, can solve problems such as insufficient sensitivity, and achieve the effects of low cost, rich aroma components, and convenient equipment assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

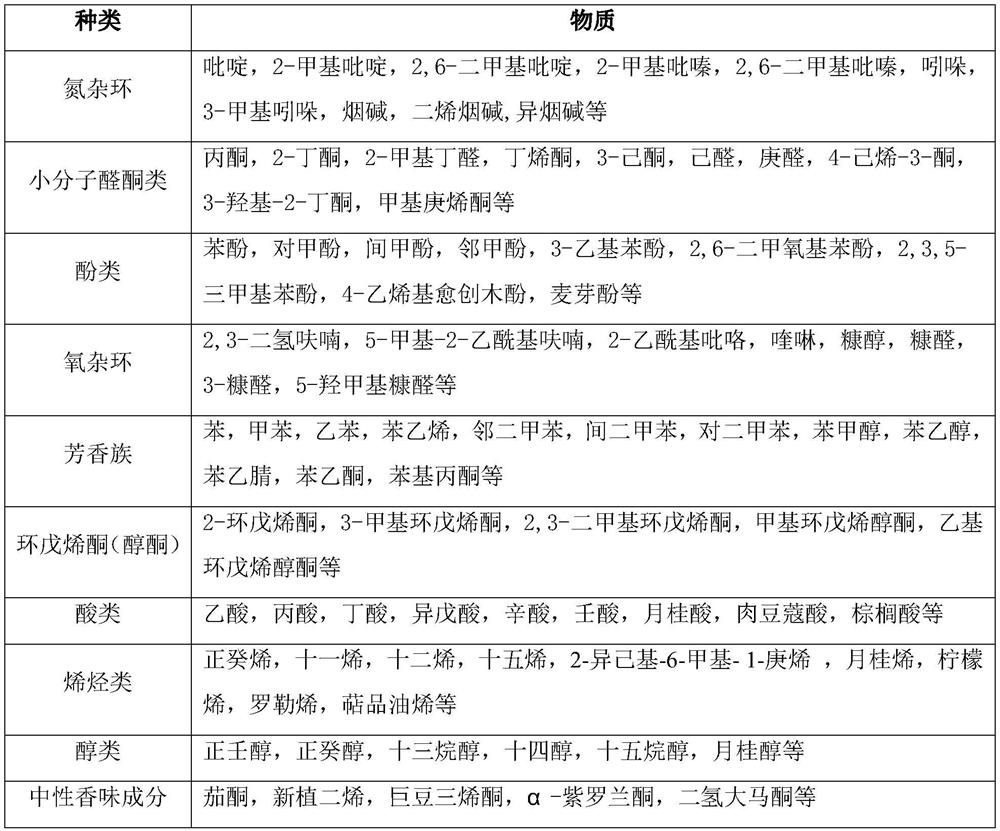

Examples

Embodiment 1

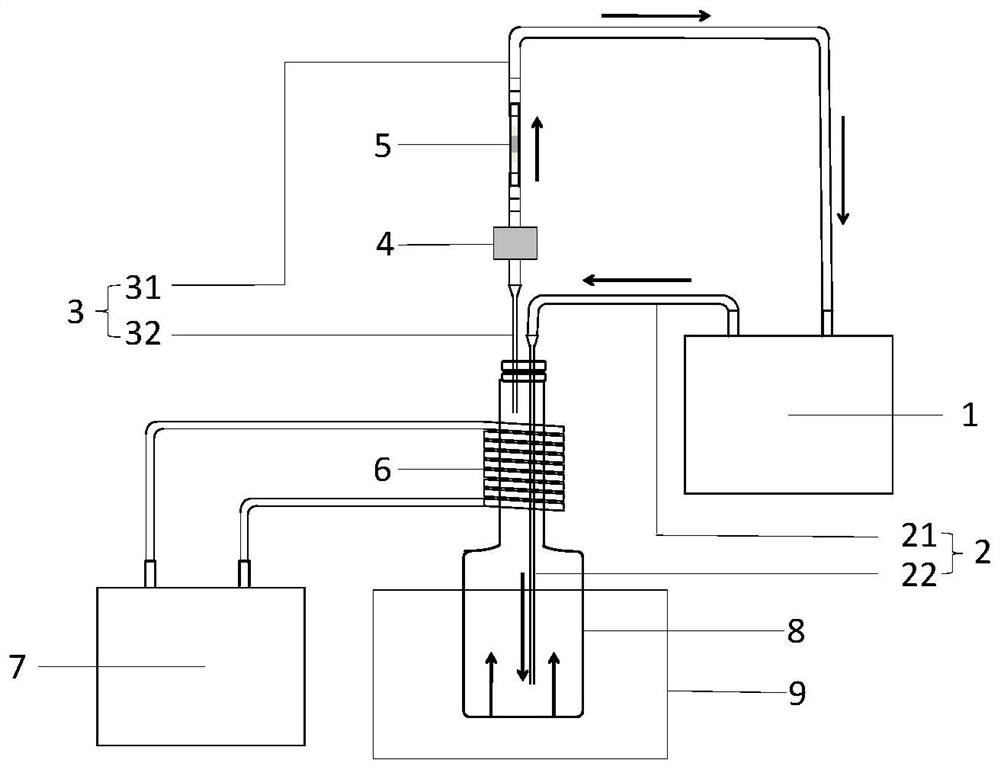

[0118] The analysis method of aroma component in the present embodiment tobacco, the steps are as follows:

[0119] 1) Use a smoking machine to smoke the cigarettes, use the Cambridge filter to capture the mainstream smoke, put the Cambridge filter into the flask, put the flask into a temperature-controlled water bath heating pot, and heat it at 70°C for 15 minute;

[0120] 2) After equilibration, continue to heat the sample bottle through a temperature-controlled water bath heating pot, the heating temperature is 70°C, and use an electric diaphragm air pump to prepare air. The outlet flow rate of the electric diaphragm air pump is 800mL / min, and the sample in the sample bottle is Purging for 18 hours;

[0121] 3) The purge air was enriched using an adsorption liner (0.25 inches in diameter and 3.5 inches in length) packed with 200 mg of Tenax sorbent. The adsorption liner is connected with the long-necked bottle, spiral condenser, heating module and circulating stripping pu...

Embodiment 2

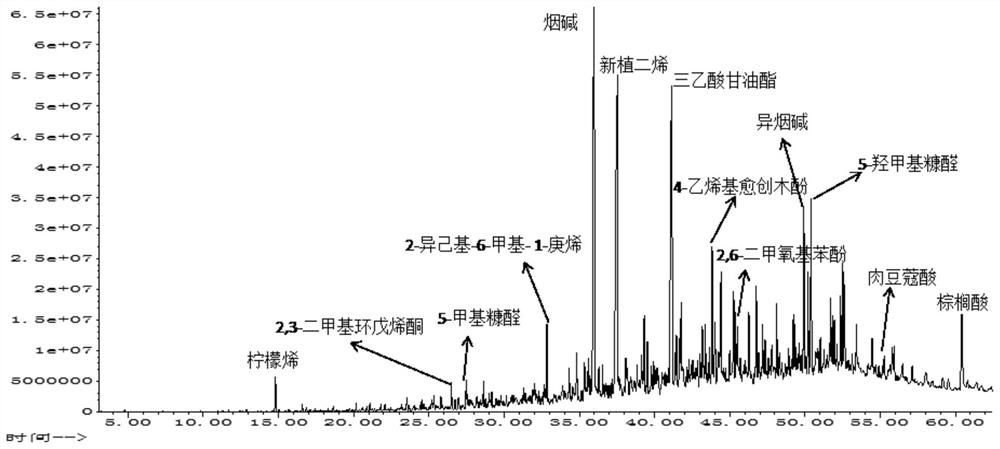

[0132] Carry out repeated investigation to the method of the present invention. The results showed that the RSDs of typical aroma components in mainstream smoke were all less than 10%, as shown in Table 2. Compared with the flue gas data obtained by the conventional solvent extraction method (using 50mL organic reagent to extract the Cambridge filter, 1uL sample injection), the response of the typical aroma components obtained by the method of the present invention is significantly increased, which is about 500 times that of the conventional solvent extraction method. This proves that the components extracted by the method of the present invention are comprehensive and typical, the relative content of each component is high, and the repeatability is good.

[0133] Table 2

[0134]

Embodiment 3

[0136] Select 100g of shredded tobacco and put it into a long-necked sample bottle, and heat and balance it in a water bath at 40°C for 15 minutes. Then, the equilibrated shredded tobacco was kept heated at 40°C, and air was continuously purged through the air inlet pipe into the long-necked sample bottle by the circulating blowing pump. The air purging flow rate was 1000ml / min, and the purging time was 24h. The gas for purging shredded tobacco was condensed at 5°C by the spiral condenser tube, and was then fed into the adsorption liner through the gas outlet pipe for enrichment for 24 hours. Finally, the adsorption liner enriched with aroma components was taken out and analyzed by thermal desorption-gas chromatography-mass spectrometry. Analyze with technology. In addition, the adsorption liner enriched with aroma components can also be taken out, and eluted with absolute ethanol 3 times, each time 2mL, to obtain the desired aroma component samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com