Biological deodorizing composite filler and preparation method thereof

A composite packing and biological deodorization technology, applied in the field of deodorizing packing, can solve the problems of restricting the economy, purification efficiency and service life of a biological filter tower, and achieve the effect of good deodorization effect, non-corrosion and rich organic nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

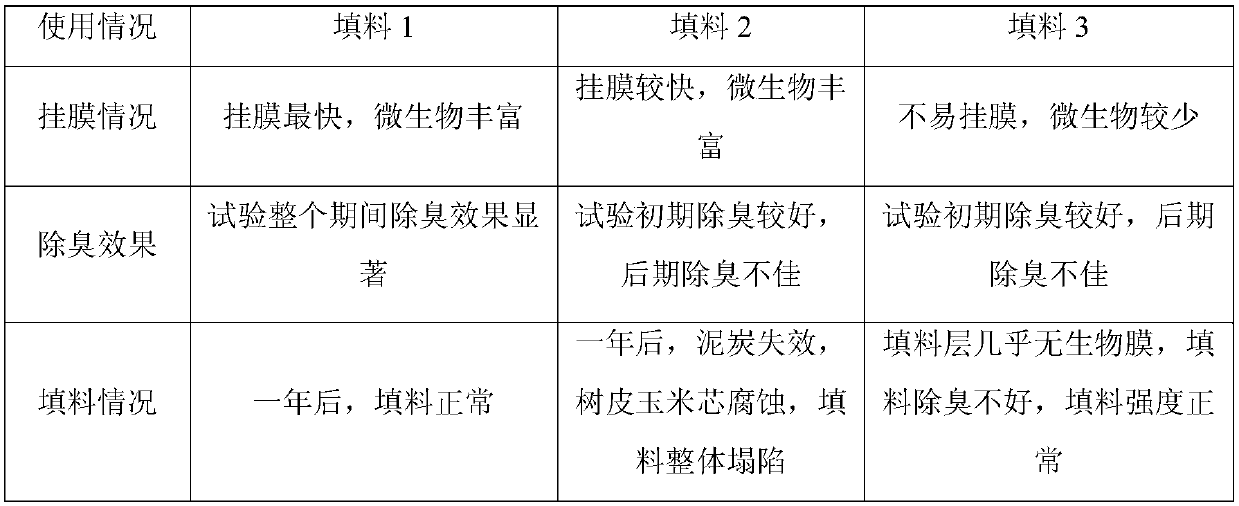

Examples

Embodiment 1

[0022] A biological deodorizing composite filler, made from the following raw materials in weight percentage: 20% of urban waste construction waste (masonry and concrete), 40% of high-calcium fly ash, 25% of leaf powder, binder (vinyl acetate- Ethylene copolymer emulsion) 15%.

[0023] The leaf powder is prepared by the following treatment: after drying the leaves at 105° C. for 2 hours, grinding them into powder with a grinder, and passing through a 35-mesh sieve, the size of the leaf powder is less than 0.5 mm.

[0024] The preparation method of described biological deodorization composite filler comprises the following steps:

[0025] 1) Process waste construction waste into particles with a size of 1-5mm;

[0026] 2) High-calcium fly ash and leaf powder were mixed in proportion for 30 minutes, followed by adding binder and water to mix to obtain a mixed slurry; in step 2), the added water was 0.8 times the sum of the weight of each raw material;

[0027] 3) The obtained ...

Embodiment 2

[0029] A biological deodorizing composite filler, made from the following raw materials in weight percentage: 25% of urban waste construction waste (masonry and concrete), 35% of high-calcium fly ash, 20% of leaf powder, binder (vinyl acetate- Ethylene copolymer emulsion) 20%.

[0030] The leaf powder is prepared by the following treatment: after drying the leaves at 105° C. for 2 hours, grinding them into powder with a grinder, and passing through a 35-mesh sieve, the size of the leaf powder is less than 0.5 mm.

[0031] The preparation method of described biological deodorization composite filler comprises the following steps:

[0032] 1) Process waste construction waste into particles with a size of 1-5mm;

[0033] 2) High-calcium fly ash and leaf powder were mixed in proportion for 30 minutes, followed by adding binder and water to mix to obtain a mixed slurry; in step 2), the added water was 0.6 times the sum of the weight of each raw material;

[0034] 3) The obtained ...

Embodiment 3

[0036] A biological deodorizing composite filler, made from the following raw materials in weight percentage: 30% of urban waste construction waste (masonry and concrete), 30% of high-calcium fly ash, 30% of leaf powder, binder (vinyl acetate- Ethylene copolymer emulsion) 10%.

[0037] The leaf powder is prepared by the following treatment: after drying the leaves at 105° C. for 2 hours, grinding them into powder with a grinder, and passing through a 35-mesh sieve, the size of the leaf powder is less than 0.5 mm.

[0038] The preparation method of described biological deodorization composite filler comprises the following steps:

[0039] 1) Process waste construction waste into particles with a size of 1-5mm;

[0040] 2) High-calcium fly ash and leaf powder were mixed in proportion for 30 minutes, and binder and water were added in turn to mix to obtain a mixed slurry; in step 2), the water added was 1 times the sum of the weight of each raw material;

[0041] 3) The obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com