Coating machine and coating method

A coating machine and mechanical pump technology, applied in the field of liquid crystal display processing, can solve the problems of low fragmentation rate of TFT liquid crystal display screen, high impact force of the display screen, etc., to improve processing yield, reduce fragmentation rate and control effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

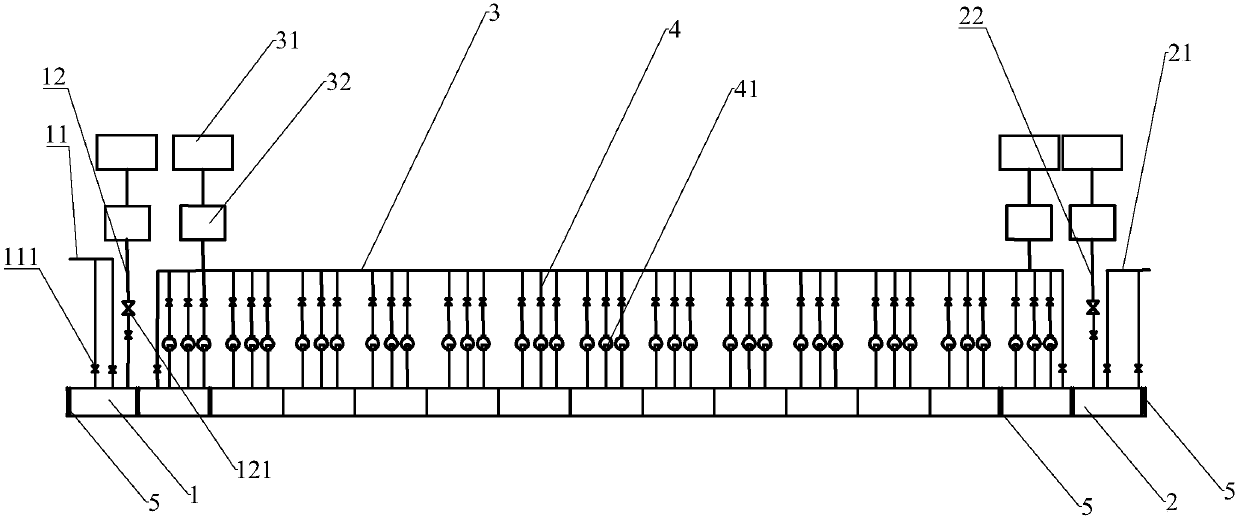

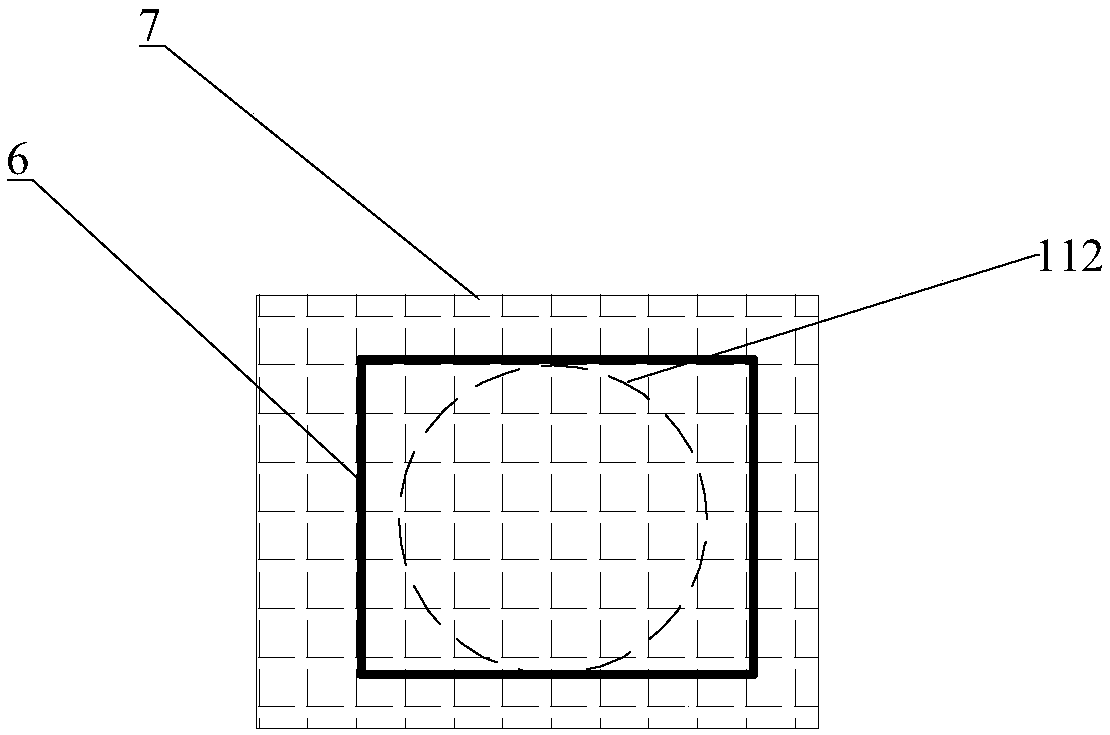

[0021] Such as figure 1 , figure 2 As shown, a coating machine includes a plurality of sequentially connected cavities, the cavities include M1, M2, M3...M13, M14, M15 cavities, M1, M15 cavities are low vacuum cavities, M2, M14 cavities It is a transition chamber with a vacuum degree of 10 -4 Pa, M3 to M13 are high vacuum chambers. The M1 cavity 1 is provided with an air outlet pipe 11 and a first vacuum pipe 12, and the M15 cavity 2 is provided with an air inlet pipe 21 and a second vacuum pipe 22. The ends of the air outlet pipe 11 and the air inlet pipe 21 are respectively connected to the atmosphere. , The body of the intake pipe 21 is provided with at least one vacuum valve 111, and the first vacuum pipe 12 and the second vacuum pipe 22 are respectively provided with a mechanical pump 31, a Luoqi pump 32, and a butterfly valve 121; The air outlet 112 connected to the air outlet pipe 11 is provided with a first filter screen 7 on the air outlet 112, and a baffle 6 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com