Fermentation method of noni enzyme

A technology of noni enzyme and fermentation method, which is applied in the field of noni enzyme fermentation, can solve the problems of less dissolution of active ingredients, poor application efficacy, and inability to fully retain the nutrition of noni fruit, so as to improve multiple symptoms and improve the effect , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

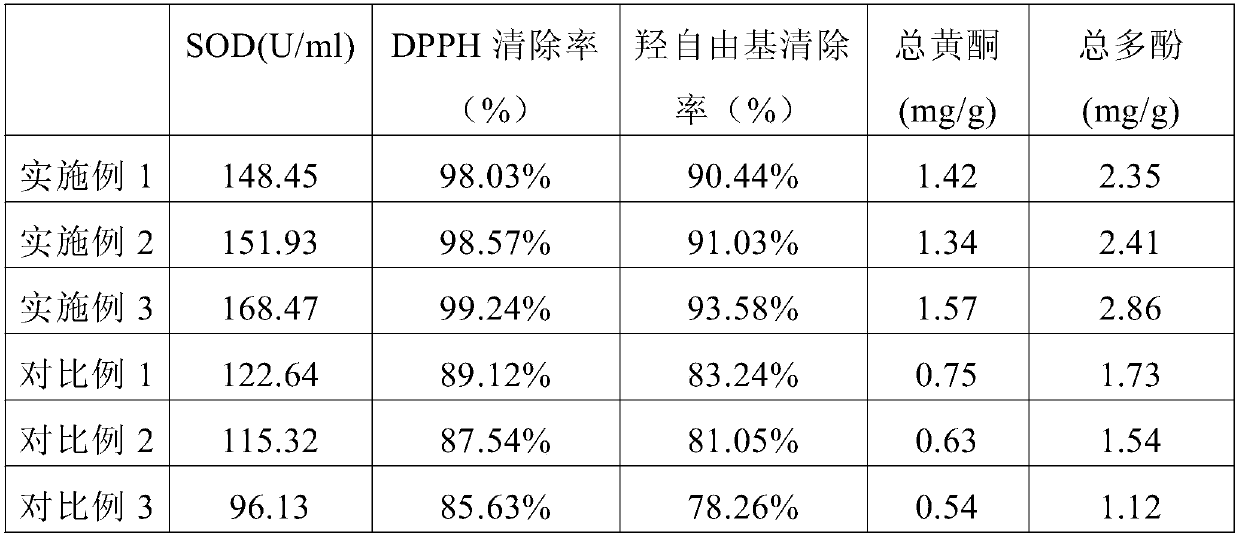

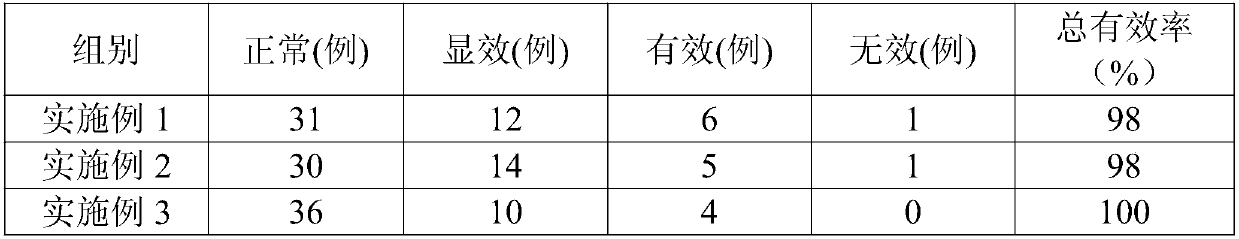

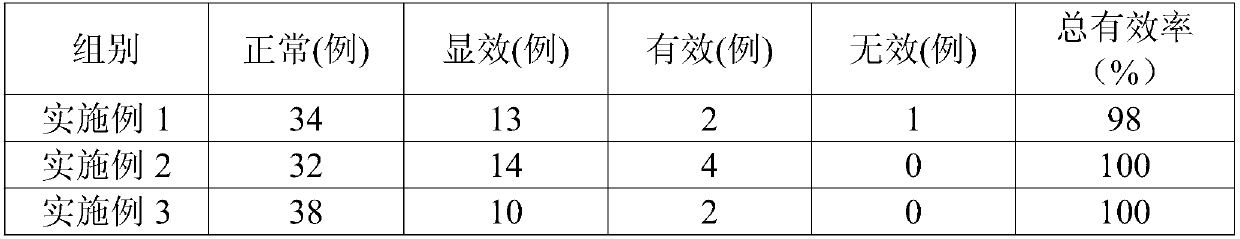

Examples

Embodiment 1

[0025] A fermentation method of Noni ferment, comprising the following steps:

[0026] S1. Pre-treatment: Screen the fresh noni fruit, wash and place in dilute acetic acid solution with a volume concentration of 2%, heat up to 50°C and soak for 20 minutes;

[0027] S2, steam explosion: put the soaked Noni fruit into a steam explosion tank, feed steam, and maintain the pressure at 2MPa for 150s;

[0028] S3. One-time sterilization: the material after steam explosion is sterilized by ultra-high temperature instantaneous sterilization, the temperature of the ultra-high temperature instantaneous sterilization is 120° C., and the time is 8 seconds;

[0029] S4, primary fermentation: the sterilized material is packed into a fermenter, and 10 g of starter A is added to every kilogram of Noni fruit, and the starter A is composed of Phylopora spp. with a mass ratio of 1:0.6:0.4 fermented under the condition of 38-42°C for 15 days, stirring once every 5 days to obtain the initial ferme...

Embodiment 2

[0036] A fermentation method of Noni ferment, comprising the following steps:

[0037] S1. Pre-treatment: Screen the fresh noni fruit, wash and place in a dilute acetic acid solution with a volume concentration of 4%, and heat up to 60°C for soaking for 10 minutes;

[0038] S2, steam explosion: put the soaked Noni fruit into the steam explosion tank, feed steam, keep the pressure at 4MPa, and the time is 100s;

[0039] S3. One-time sterilization: the material after steam explosion is subjected to ultra-high temperature instantaneous sterilization, the temperature of the ultra-high temperature instantaneous sterilization is 130° C., and the time is 5 seconds;

[0040] S4, primary fermentation: the sterilized material is packed into a fermenter, and 15g of starter A is added to every kilogram of Noni fruit, and said starter A is made of Phylonotus rhizome with a mass ratio of 1:0.8:0.6 fermented at 38-42°C for 25 days and stirred once every 10 days to obtain the initial ferment...

Embodiment 3

[0047] A fermentation method of Noni ferment, comprising the following steps:

[0048] S1. Pre-treatment: Screen the fresh noni fruit, wash and place in a dilute acetic acid solution with a volume concentration of 3%, heat up to 55°C and soak for 15 minutes;

[0049] S2, steam explosion: put the soaked Noni fruit into the steam explosion tank, feed steam, keep the pressure at 3MPa, and the time is 120s;

[0050] S3. One-time sterilization: the material after steam explosion is subjected to ultra-high temperature instantaneous sterilization, the temperature of the ultra-high temperature instantaneous sterilization is 125° C., and the time is 6 seconds;

[0051] S4, primary fermentation: the sterilized material is packed into a fermenter, and 13g of starter A is added to every kilogram of Noni fruit, and said starter A is made of Phlomofora rubrum with a mass ratio of 1:0.7:0.5 fermented under the condition of 38-42°C for 20 days, stirring once every 5 days to obtain the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com