Method for preparing Fe-MFI microporous molecular sieve

A technology of microporous molecular sieve and deionized water, which is applied in the direction of iron silicate and crystalline aluminosilicate zeolite, etc., can solve the problems of application limitation, poor hydrothermal stability, lack of acidity, etc., and achieve good selectivity and cost The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

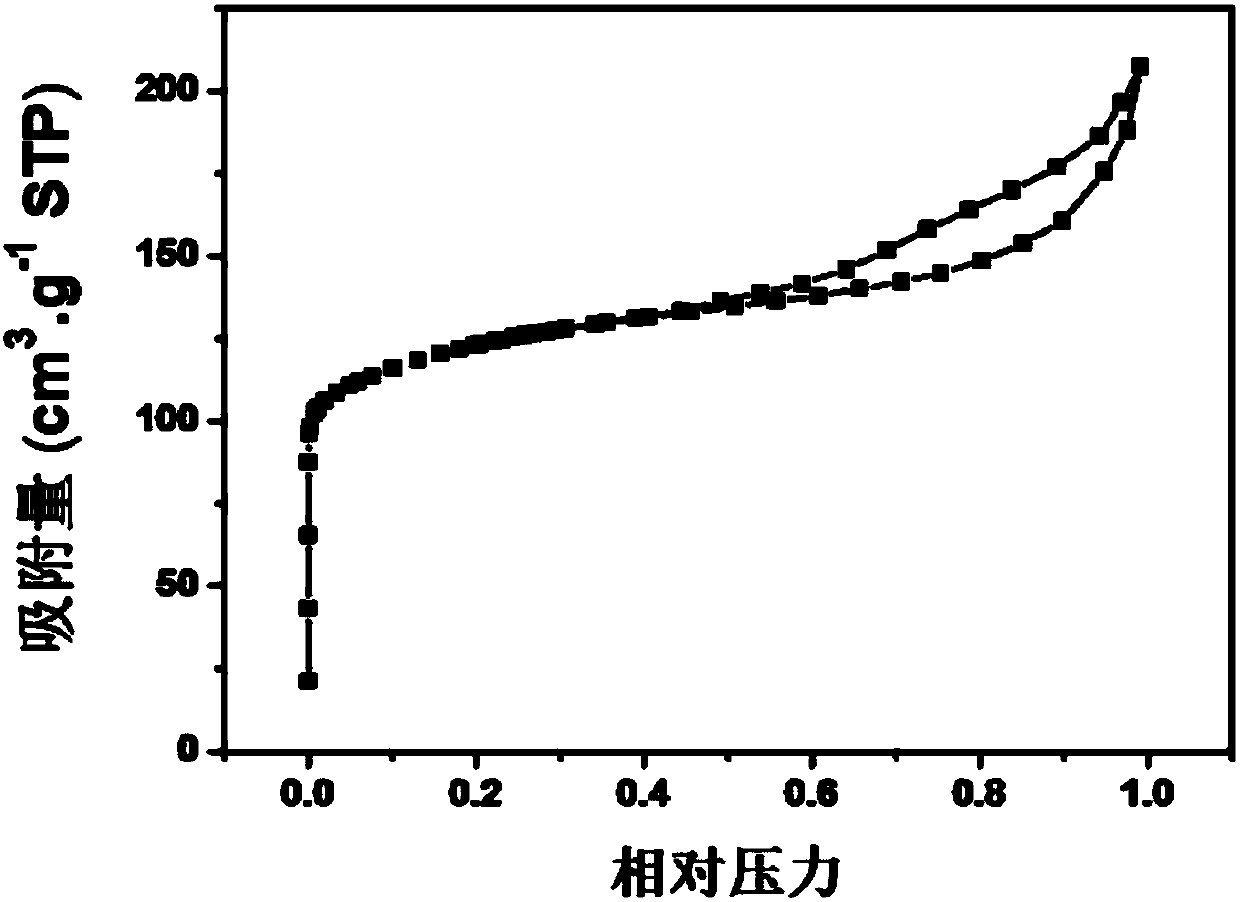

Method used

Image

Examples

Embodiment 1

[0030] Take 2.91g Fe(NO 3 ) 3 ﹒ 9H 2 O and 1.072g TEA are placed in a 50ml beaker, add a small amount of deionized water, and dissolve on a constant temperature magnetic stirrer.

[0031] After the dissolution is complete, put the solution into an ice-water bath, drop 61.54g of tetrapropylammonium hydroxide TPAOH solution (40wt%) in about 30min, add 17.20g of TEOS dropwise after the addition is completed and stir for 1h, at room temperature Under stirring for 10h.

[0032] Place the beaker containing the solution in a magnetic heating stirrer at 80°C to evaporate the ethanol. After the ethanol is evaporated, transfer the solution in the beaker to a polytetrafluoroethylene-lined reaction kettle, add a small amount of deionized water, and place at 80 The reaction was carried out at ℃ for 24 hours, and it was taken out and stored in a refrigerator at low temperature.

[0033] Weigh the above seed crystals, transfer them to a plastic beaker, add A380 white carbon black silica...

Embodiment 2

[0038] Note: Steps 1) to 4) are the same as those in Example 1 and will not be repeated here.

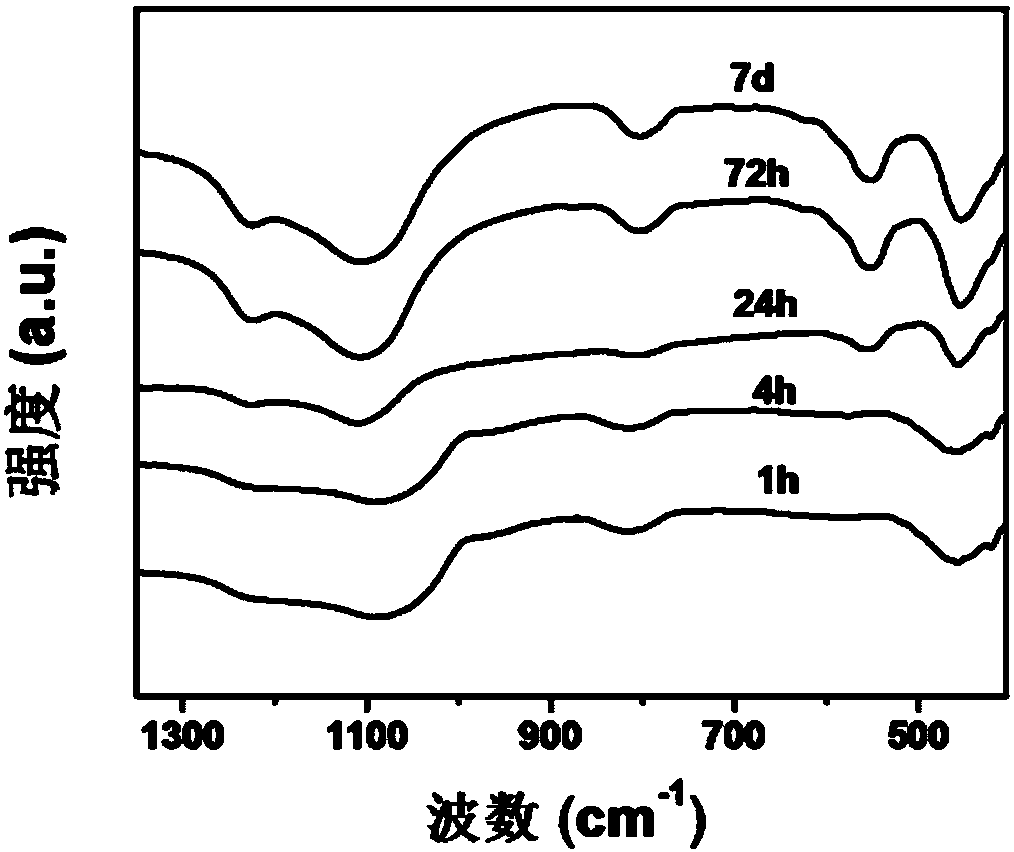

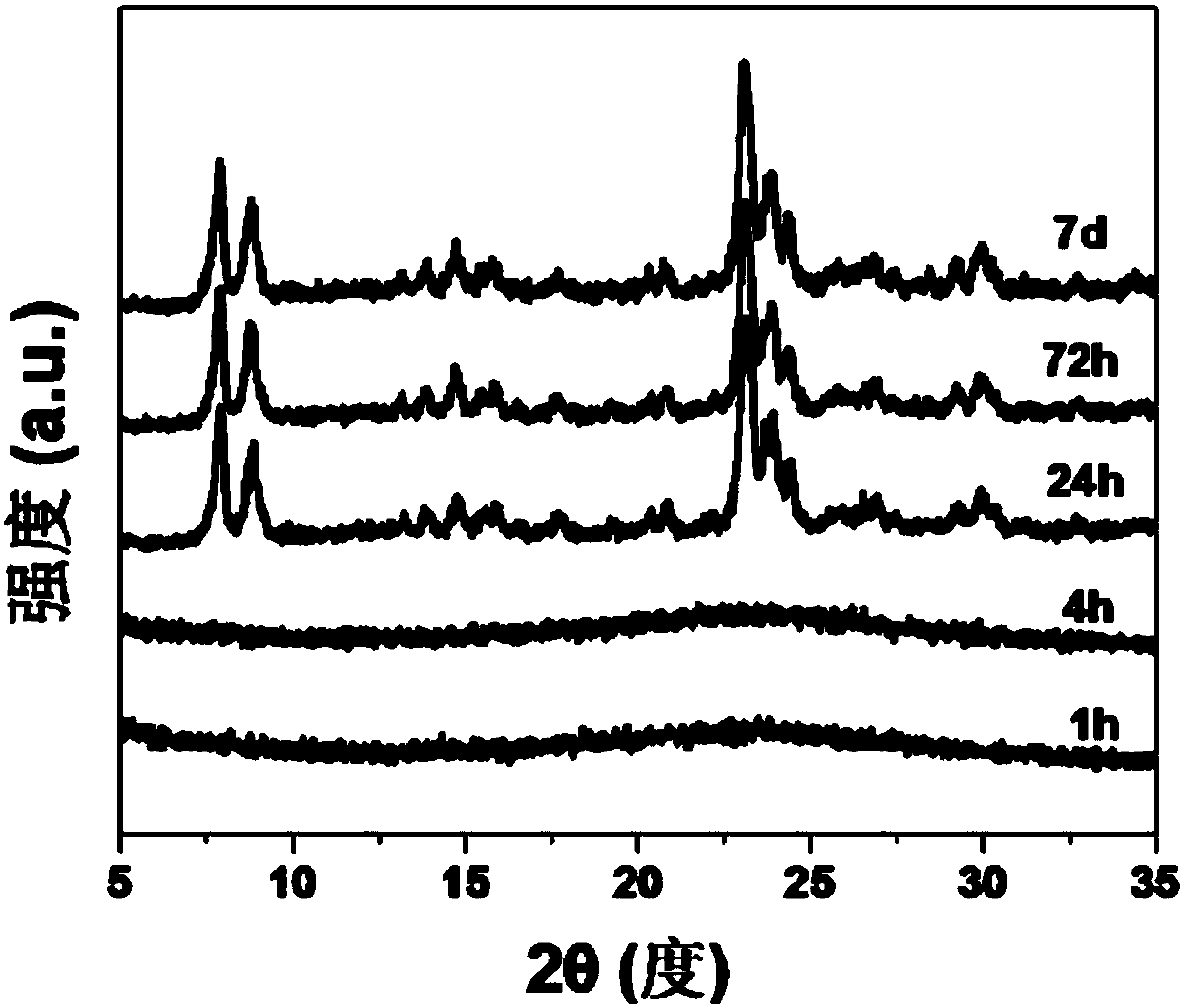

[0039] 5) Transfer the column into a high-pressure reaction kettle for crystallization for 4 hours, take out the sample and cool it, dry it in an oven at 80°C for 24 hours, and roast it at 550°C for 6 hours to obtain the sample and label it as Fe-0.2625-0.025-4h ;(0.2625TPAOH:1SiO 2 :0.025Fe(NO 3 ) 3 ﹒ 9H 2 O: 0.025TEA).

[0040] The prepared Fe-0.2625-0.025-4h sample, because the crystallization time is too short, the crystallinity is not very good. The Fe-0.2625-0.025-4h sample was used to catalyze the reaction of oxidizing toluene to prepare benzaldehyde, the conversion rate of Fe-Si molecular sieve was 0.54%, and the selectivity was 3.68%.

Embodiment 3

[0042] Note: Steps 1) to 4) are the same as those in Example 1 and will not be repeated here.

[0043] 5) Transfer the columnar material into a high-pressure reaction kettle for crystallization for 24 hours, take out the sample and cool it, dry it in an oven at 80°C for 24 hours, and roast it at 550°C for 6 hours to obtain the sample and label it as Fe-0.2625-0.025-24h, (0.2625TPAOH:1SiO 2 :0.025Fe(NO 3 ) 3 ﹒ 9H 2 O: 0.025TEA).

[0044]The prepared Fe-0.2625-0.025-24h sample has achieved a good crystallization effect after 24h of crystallization. Fe-0.2625-0.025-24h is used to catalyze the reaction of oxidizing toluene to prepare benzaldehyde, the conversion rate of iron-silicon molecular sieve is 4.82%, and the selectivity is 52.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com