Wind power blade and preparation method thereof

A technology for wind power blades and shells, applied in the field of wind power blades and their preparation, which can solve the problems of lack of toughness and unreliable strength of wind power blades, and achieve the effect of enhanced strength and toughness, simple and reasonable preparation method, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

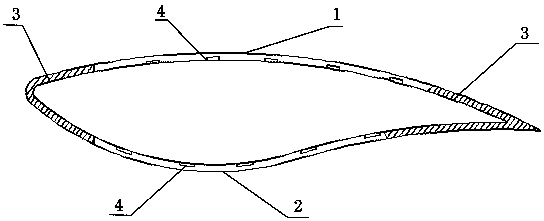

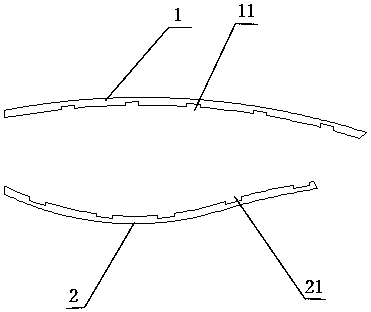

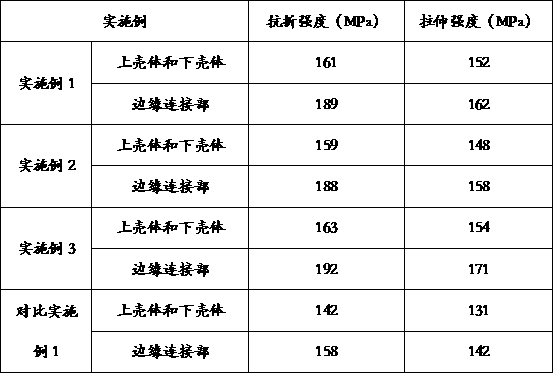

[0028] Such as figure 1 and 2 As shown, a wind turbine blade includes an upper shell 1 , a lower shell 2 , and an edge connecting portion 3 . Both ends of the upper shell 1 and the lower shell 2 are fixedly connected by two edge connecting parts 3 . The inner side of the upper housing 1 is provided with a plurality of upper arc-shaped grooves 11 . The inner side of the lower shell 2 is provided with a plurality of lower arc-shaped grooves 21 . Both the upper arc-shaped groove 11 and the lower arc-shaped groove 21 are provided with reinforcing ribs 4, and the reinforcing ribs 4 include boron fibers and gypsum whiskers, and the mass ratio of boron fibers and gypsum whiskers is 3:1. The upper shell and the lower shell include epoxy resin and nylon fiber, and the mass ratio of nylon fiber to epoxy resin is 1:5. The edge connection part includes epoxy resin, glass fiber, gypsum whisker, and nano-scale aluminum oxide, wherein the weight parts of epoxy resin, glass fiber, gypsum ...

Embodiment 2

[0035] Such as figure 1 and 2 As shown, a wind turbine blade includes an upper shell 1 , a lower shell 2 , and an edge connecting portion 3 . Both ends of the upper shell 1 and the lower shell 2 are fixedly connected by two edge connecting parts 3 . The inner side of the upper housing 1 is provided with a plurality of upper arc-shaped grooves 11 . The inner side of the lower shell 2 is provided with a plurality of lower arc-shaped grooves 21 . Both the upper arc-shaped groove 11 and the lower arc-shaped groove 21 are provided with reinforcing ribs 4, and the reinforcing ribs 4 include boron fibers and gypsum whiskers, and the mass ratio of boron fibers and gypsum whiskers is 3:1.5. The upper shell and the lower shell include epoxy resin and nylon fiber, and the mass ratio of nylon fiber and epoxy resin is 1:7. The edge connection part includes epoxy resin, glass fiber, gypsum whisker, and nano-scale aluminum oxide, wherein the weight parts of epoxy resin, glass fiber, gyps...

Embodiment 3

[0042] Such as figure 1 and 2As shown, a wind turbine blade includes an upper shell 1 , a lower shell 2 , and an edge connecting portion 3 . Both ends of the upper shell 1 and the lower shell 2 are fixedly connected by two edge connecting parts 3 . The inner side of the upper housing 1 is provided with a plurality of upper arc-shaped grooves 11 . The inner side of the lower shell 2 is provided with a plurality of lower arc-shaped grooves 21 . Both the upper arc-shaped groove 11 and the lower arc-shaped groove 21 are provided with reinforcing ribs 4, and the reinforcing ribs 4 include boron fibers and gypsum whiskers, and the mass ratio of boron fibers and gypsum whiskers is 3:2. The upper shell and the lower shell include epoxy resin and nylon fiber, and the mass ratio of nylon fiber to epoxy resin is 1:10. The edge connection part includes epoxy resin, glass fiber, gypsum whisker, and nano-scale aluminum oxide, wherein the weight parts of epoxy resin, glass fiber, gypsum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com