Method for testing yellowing of plastering gupsum

A technology for plastering plaster and testing methods, which is applied in the direction of color/spectral characteristic measurement, etc. It can solve the problems that cannot directly reflect the actual situation of the project and the yellowing of the surface coating, achieve intuitive test phenomena and results, simple operation, and reduce test costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Proceed as follows:

[0033] (1) Paint one coat of white primer (without adding general primer) on two cement mortar blocks (drying, moisture content <0.5%) of 120mm×120mm×10mm, and cure for 1d under the standard test environment;

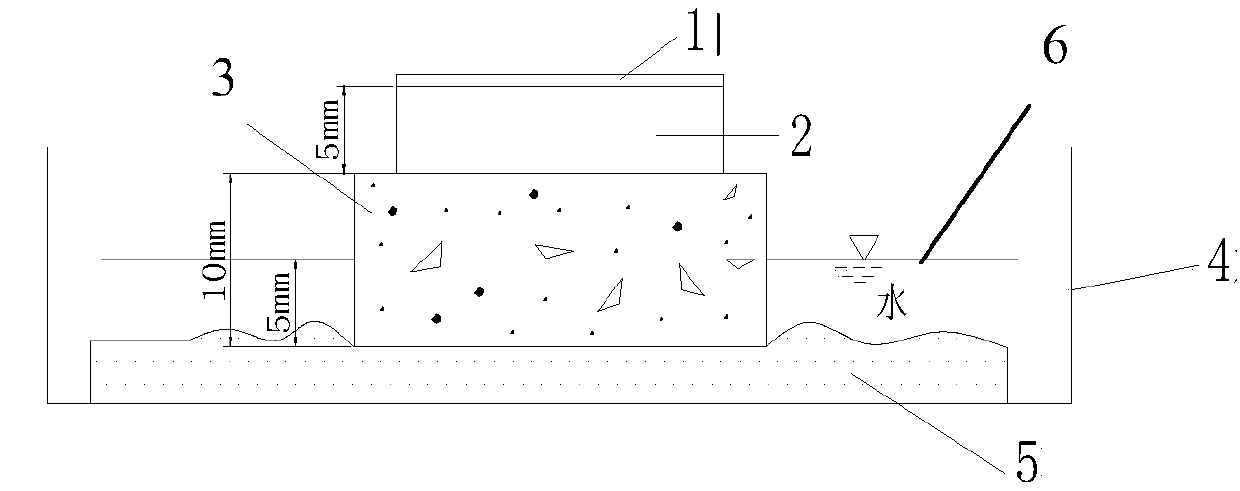

[0034] (2) Keep one piece of test piece (denoted as reference sample) in (1) and continue to maintain it under the standard test environment; the other piece of test piece (denoted as sample) is placed horizontally on the standard sand at the bottom of the water tank, and water is injected to the water surface. At about 5mm on the surface of the mortar block, let it stand still, and observe whether the primer surface of the two test pieces is discolored and yellowed at 4h, 24h, 48h, and 96h respectively.

[0035] In order to study the influence of the moisture content of the base material cement mortar block on the yellowing property of the plastering gypsum, the implementation cases 2, 3 and 4 were designed.

Embodiment 2

[0037] Proceed as follows:

[0038] (1) Place a hard polyvinyl chloride or metal frame with a size of 100mm×100mm×5mm on a 120mm×120mm×10mm cement mortar block (moisture content 14%), fill the frame with plastering plaster, and smooth it with a scraper Surface, after 5 minutes remove the molded frame to be the test piece;

[0039] (2) After the two specimens were cured for 1 day under the standard test environment, they were painted with a white primer (no general primer added); and then cured for 1 day under the standard test environment;

[0040] (3) Continue to maintain one piece of test piece (denoted as reference sample) in (2) under the standard test environment; the other piece of test piece (denoted as sample) is placed horizontally on the standard sand at the bottom of the water tank, and the water is injected to the water surface and the distance from the cement At about 5mm on the surface of the mortar block, let it stand still, and observe whether the primer surfa...

Embodiment 3

[0042] Proceed as follows:

[0043] (1) Place a hard polyvinyl chloride or metal frame with a size of 100mm×100mm×5mm on a cement mortar block (water content 20%) of 120mm×120mm×10mm, fill the frame with plastering plaster, and smooth it with a scraper Surface, after 5 minutes remove the molded frame to be the test piece;

[0044] (2) After the two specimens were cured for 1 day under the standard test environment, they were painted with a white primer (no general primer added); and then cured for 1 day under the standard test environment;

[0045](3) Continue to maintain one piece of test piece (denoted as reference sample) in (2) under the standard test environment; the other piece of test piece (denoted as sample) is placed horizontally on the standard sand at the bottom of the water tank, and the water is injected to the water surface and the distance from the cement At about 5mm on the surface of the mortar block, let it stand still, and observe whether the primer surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com