Preparation method of special function textile fiber

A technology of textile fibers and functions, applied in the field of preparation of special functional textile fibers, can solve the problems of low fiber durability, low fiber functional efficiency, and low durability of special functional textile fibers, so as to solve the problems of fiber durability. Not high, improve the functional effect, save the effect of functional raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the special functional textile fiber of the present invention, the special functional textile fiber includes a functional device and a polymer material fiber layer coated on the outer peripheral surface of the functional device, which includes the following steps: (a) making the polymer material into Prefabricated rod, processing the preformed rod to form a hollow cavity inside, filling the hollow cavity with functional material to form the functional device, and then sealing the end; or, after softening the polymer material and the functional device in the mold Composite, and extrusion molding to form the polymer material fiber layer on the outer peripheral surface of the functional device; (b) stretching the preform obtained in step (a) to obtain special functional textile fibers. In this way, the structural control of the distribution of functional materials can be carried out, which can effectively improve its functional effect, save functio...

Embodiment 1

[0030] This embodiment provides a preparation method of special functional textile fibers (conductive fibers), which includes the following steps:

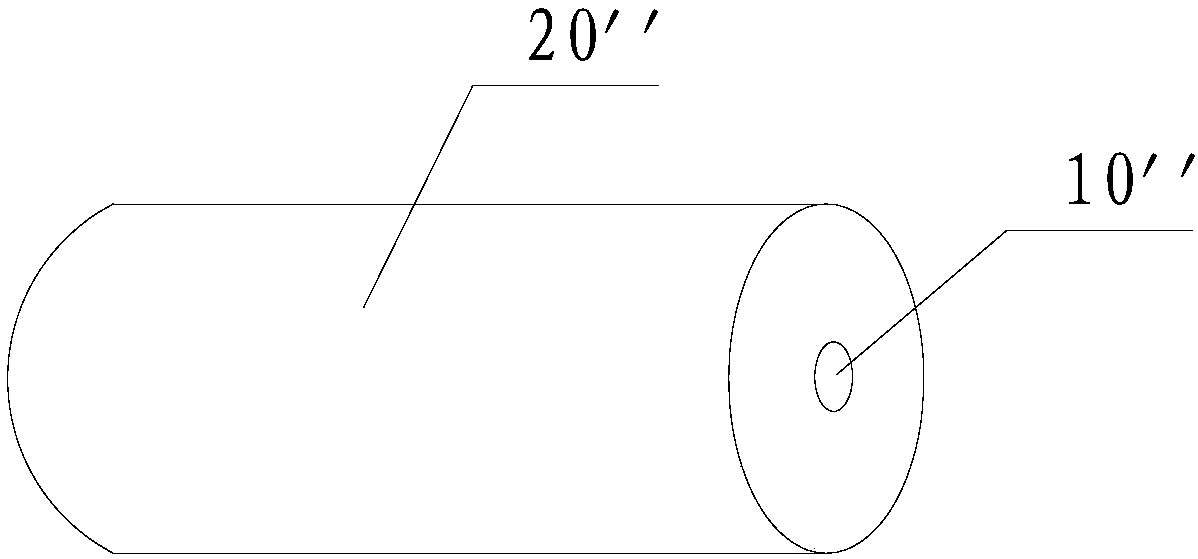

[0031] (a) Using the existing technology, the PET material is extruded through a mold to produce a preform 20'', which has high transparency and is conducive to observing the distribution of its internal structure; the PET preform 20'' is drilled , grinding and other mechanical processing, so that the middle part forms a hollow structure (the diameter of the hollow structure is 1~2mm, such as figure 1 shown), and then fill it with conductive carbon powder (specific surface area 36 m 2 / g, specific resistance 2.3×10 -1 Ωm, specific gravity 1.8, particle size less than 25nm, purity 99.9%), compacted to form functional devices 10'', both ends sealed with resin;

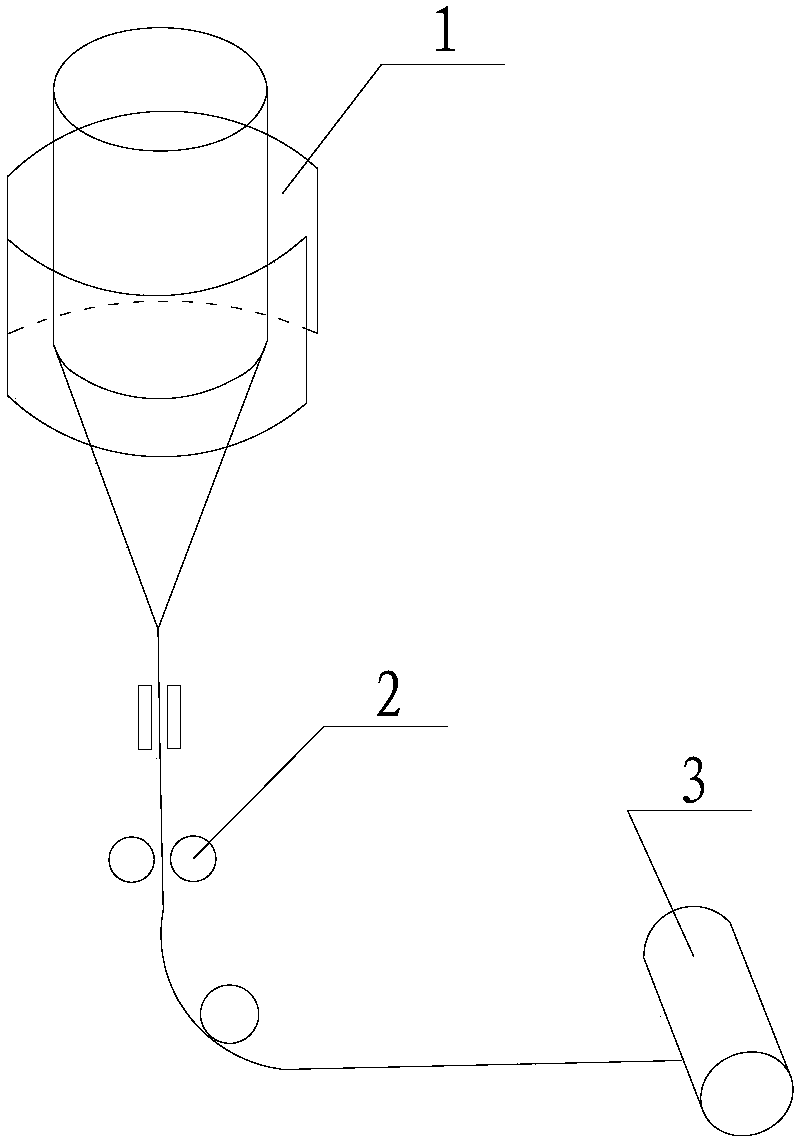

[0032] (b) using such as image 3 The equipment shown is stretching and forming, specifically: the preform 20'' is fixed and sent to the furnace 1, and the temperature i...

Embodiment 2

[0034] This embodiment provides a kind of preparation method of special functional textile fiber (far-infrared health-care fiber), which comprises the following steps:

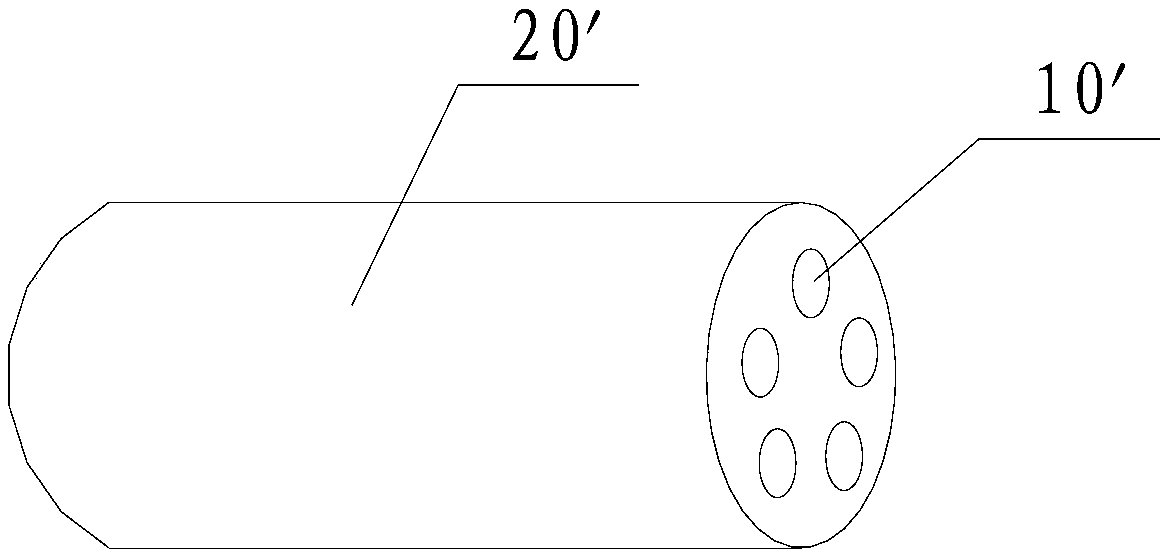

[0035] (a) Using the existing technology, the PET material is extruded through a mold to obtain a preform 20', which has high transparency and is conducive to observing the distribution of its internal structure; the PET preform 20' is drilled and polished and other mechanical processing, so that the middle part forms multiple hollow structures parallel to each other (the diameter of each hollow structure is 1~2mm, such as figure 2 shown), and then fill it with Taichi stone far-infrared powder (the particle size of Taichi stone powder is about 100nm; the preparation method is: calcinate Taichi stone minerals at about 1000°C, cool naturally and grind to obtain Taiji Far-infrared stone powder), compacted to form a functional device 10', and both ends are sealed with resin;

[0036] (b) using such as image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com