Lipid oxidation control process in casing processing

A technology for casings and lipids, which is applied in the field of lipid oxidation control of casings, can solve the problems of oxidative decomposition, deterioration of casing quality, poor antioxidant performance, etc., and achieve the effect of enhancing antioxidant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the lipid oxidation control process in casing processing, the control process includes the following steps:

[0020] (1) Selection of raw material liquid: The raw material liquid is composed of the following components in parts by weight: 0.1 part of D-sodium erythorbate, 1 part of citric acid, 0.1 part of disodium edetate, trimeric Sodium phosphate is 0.1 part, phytic acid is 0.1 part and vitamin C sodium is 1 part;

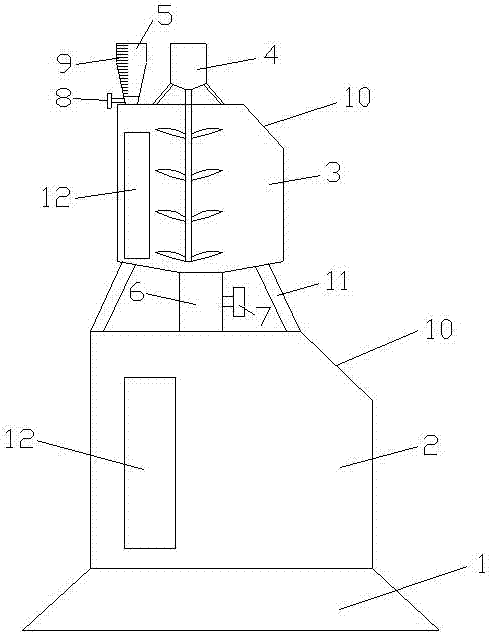

[0021] (2) Anti-oxidation treatment: import the components of the raw material liquid into the funnel 5, and then open the stop valve 8 after measurement, so that the components of the raw material flow into the raw material barrel 3, and after the Qidong mixer fully mixes, Open the one-way valve 7 again, make the raw material industry in the raw material tank 3 flow in the soaking tank 2 through the guide pipe 6, then fully soak the fresh casings in it for 16-24 hours at normal temperature.

[0022] Tested one month later, the casing...

Embodiment 2

[0025] In this embodiment, the lipid oxidation control process in casing processing, the control process includes the following steps:

[0026] (1) Selection of raw material liquid: The raw material liquid is composed of the following components by weight: 0.8 parts of D-sodium erythorbate, 3 parts of citric acid, 0.5 parts of disodium ethylenediaminetetraacetic acid, trimeric 0.5 parts of sodium phosphate, 0.5 parts of phytic acid and 2 parts of sodium vitamin C;

[0027] (2) Anti-oxidation treatment: import the components of the raw material liquid into the funnel 5, and then open the stop valve 8 after measurement, so that the components of the raw material flow into the raw material barrel 3, and after the Qidong mixer fully mixes, Open the one-way valve 7 again, make the raw material industry in the raw material tank 3 flow in the soaking tank 2 through the guide pipe 6, then fully soak the fresh casings in it for 16-24 hours at normal temperature.

[0028] Tested one mo...

Embodiment 3

[0031] In this embodiment, the lipid oxidation control process in casing processing, the control process includes the following steps:

[0032] (1) Selection of raw material liquid: The raw material liquid is composed of the following components in parts by weight: 0.45 parts of D-sodium erythorbate, 2 parts of citric acid, 0.3 parts of disodium ethylenediaminetetraacetic acid, trimeric 0.3 parts of sodium phosphate, 0.3 parts of phytic acid and 1.5 parts of sodium vitamin C;

[0033] (2) Anti-oxidation treatment: import the components of the raw material liquid into the funnel 5, and then open the stop valve 8 after measurement, so that the components of the raw material flow into the raw material barrel 3, and after the Qidong mixer fully mixes, Open the one-way valve 7 again, make the raw material industry in the raw material tank 3 flow in the soaking tank 2 through the guide pipe 6, then fully soak the fresh casings in it for 16-24 hours at normal temperature.

[0034] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com