A kind of preparation method of porous metal organic framework material hkust-1

A HKUST-1, metal-organic framework technology, applied in the field of preparation of porous metal-organic framework material HKUST-1, can solve problems such as inability to efficiently remove residues, product quality and stability cannot be guaranteed, and affect product quality. The cost is green and pollution-free, prevents by-products, and is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as figure 1 As shown, a preparation method of porous metal-organic framework material HKUST-1 includes the following steps: S1: Make a mixed solution of copper source and benzenetricarboxylic acid by hydrothermal method, and dry the mixed solution to obtain the initial HKUST-1 solid ; S2: The initial HKUST-1 solid was ground into powder, dissolved in methanol for activation, and the activated precipitate was dried to obtain the HKUST-1 material.

[0040] The step S1 includes the following specific steps:

[0041] S100: Weigh Cu(NO 3 ) 2 ·3H 2 O was dissolved in deionized water to obtain a copper source solution, and trimesic acid was weighed and dissolved in ethanol to obtain a trimesic acid solution.

[0042] S110: heating the copper source solution and the trimesic acid solution to 30-80° C. and mixing, respectively, to obtain a first mixed solution.

[0043] S120: heating the first mixed solution at 30-80° C. for 3-5 hours, and stirring during the heating p...

Embodiment 2

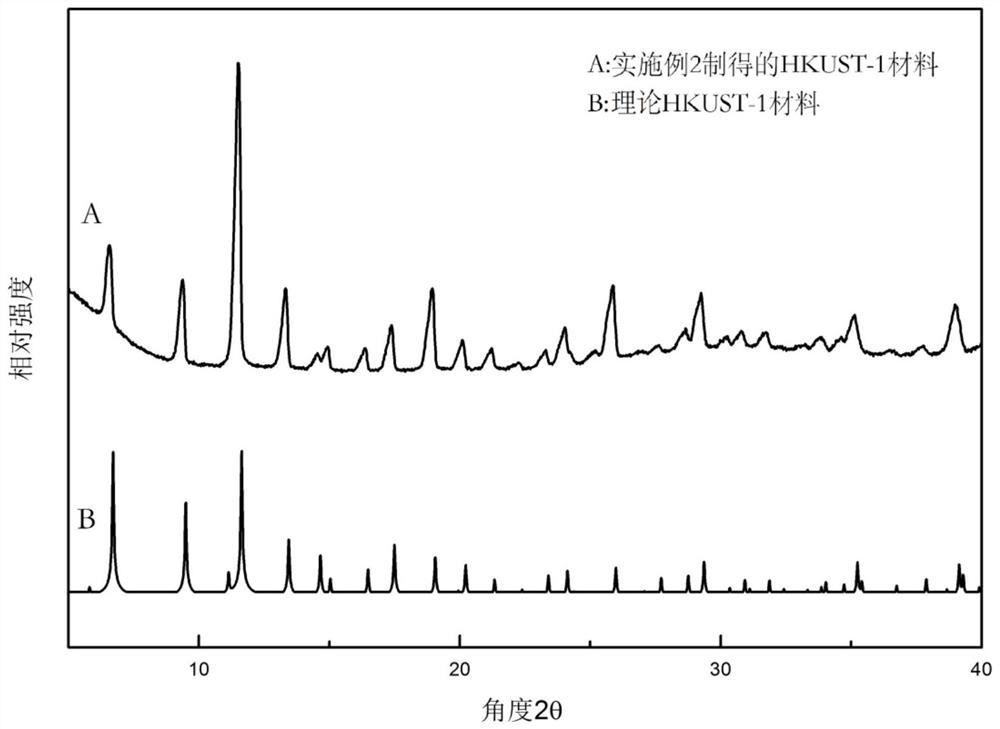

[0054] 6.5g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 200 mL of deionized water to obtain a copper source solution, and 3.5 g of trimesic acid was dissolved in 200 mL of ethanol to obtain a trimesic acid solution. The copper source solution and the trimesic acid solution were respectively heated to 40° C., and then mixed into a round bottom flask to obtain a first mixed solution. Place the round-bottomed flask in a heating mantle and heat at 40°C for 3h, and stir with a rotor at a rotational speed of 200r / min. Then pour the liquid in the round-bottomed flask into a beaker, and then put it in a drying oven to dry at 80°C for 8 hours to obtain the initial HKUST-1 solid.

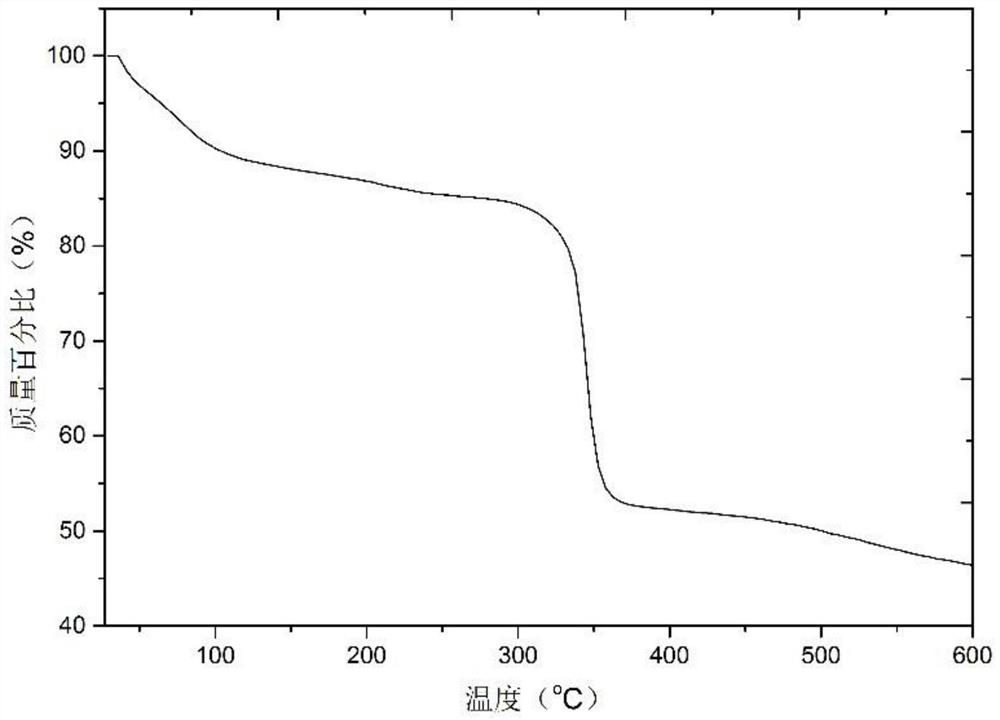

[0055]The obtained initial HKUST-1 solid was ground into powder, and immersed in 400 mL of methanol to obtain the second mixed liquid. The second mixed solution was heated to boiling, and heated under reflux for 2 hours. During the reflux heating process, the rotor was used to stir at a rotational speed of 35...

Embodiment 3

[0057] 7.5g of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 300 mL of deionized water to obtain a copper source solution, and 4.5 g of trimesic acid was dissolved in 300 mL of ethanol to obtain a trimesic acid solution. The copper source solution and the trimesic acid solution were heated to 60°C respectively, and then mixed into a round bottom flask to obtain the first mixed solution. Place the round-bottomed flask in a heating mantle and heat at 60°C for 5h, and stir with a rotor at a rotational speed of 260r / min. Then pour the liquid in the round-bottomed flask into a beaker, and then put it in a drying oven at 150°C for 12 hours to obtain the initial HKUST-1 solid.

[0058] The obtained initial HKUST-1 solid was ground into powder, and immersed in 600 mL of methanol to obtain the second mixed liquid. The second mixed solution was heated to boiling, and heated under reflux for 5 hours. During the reflux heating process, the rotor was used to stir at a rotational speed of 500 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com