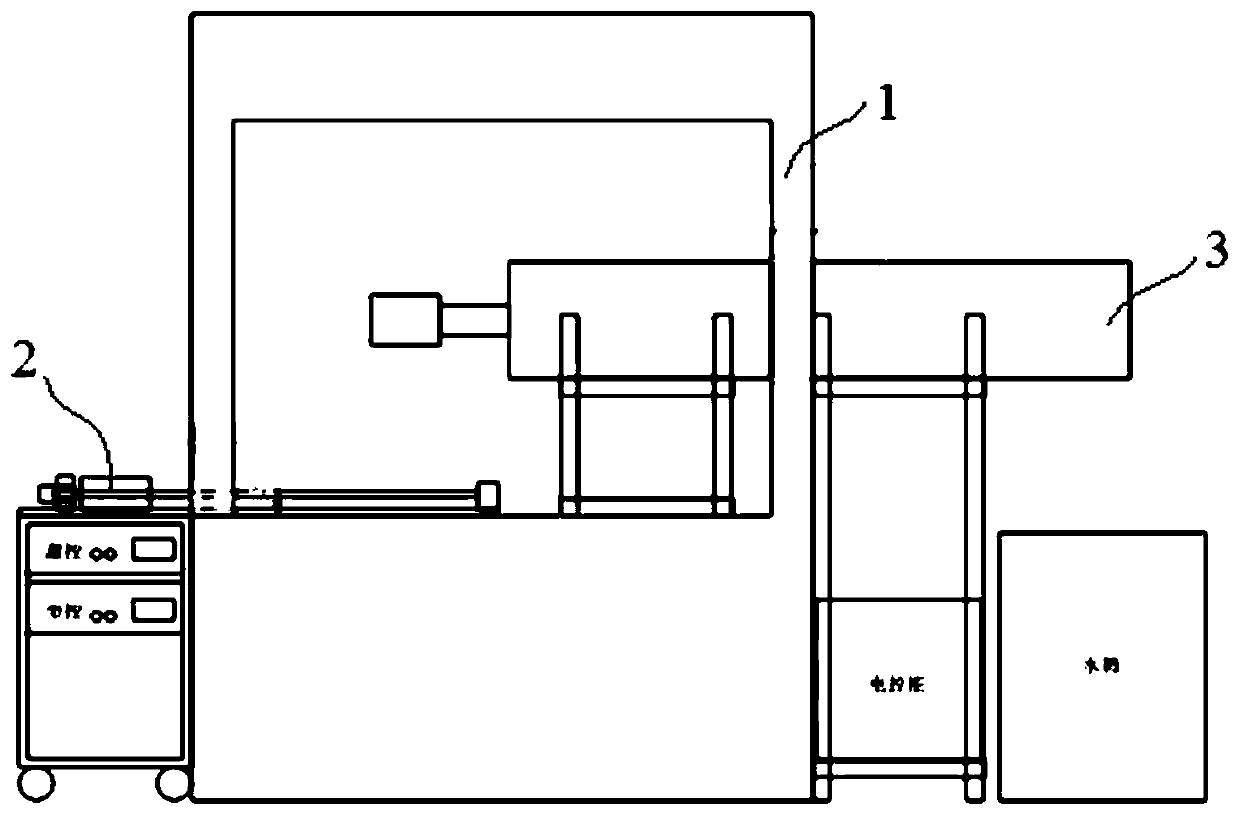

A laser-assisted heating chemical vapor deposition coating device and method

A chemical vapor deposition, laser-assisted technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of low heating efficiency and low absorption coefficient, and achieve less inclusions, low deposition temperature, and film The effect of high layer purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

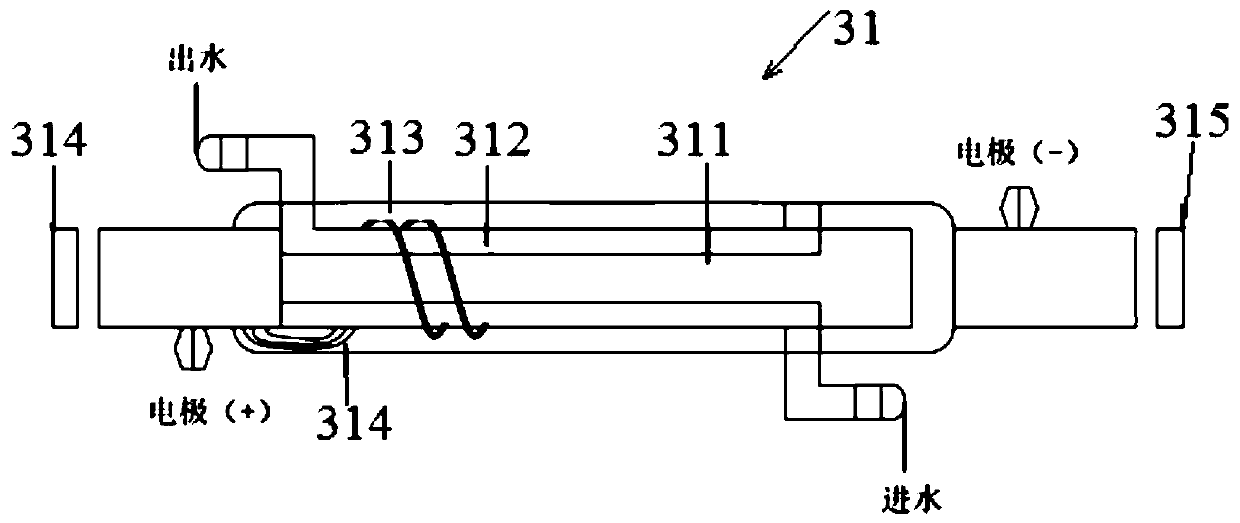

[0037] The laser-assisted heating chemical vapor deposition coating method of this embodiment includes the following steps:

[0038] Preheating step S1, using a heating device to preheat the glass substrate;

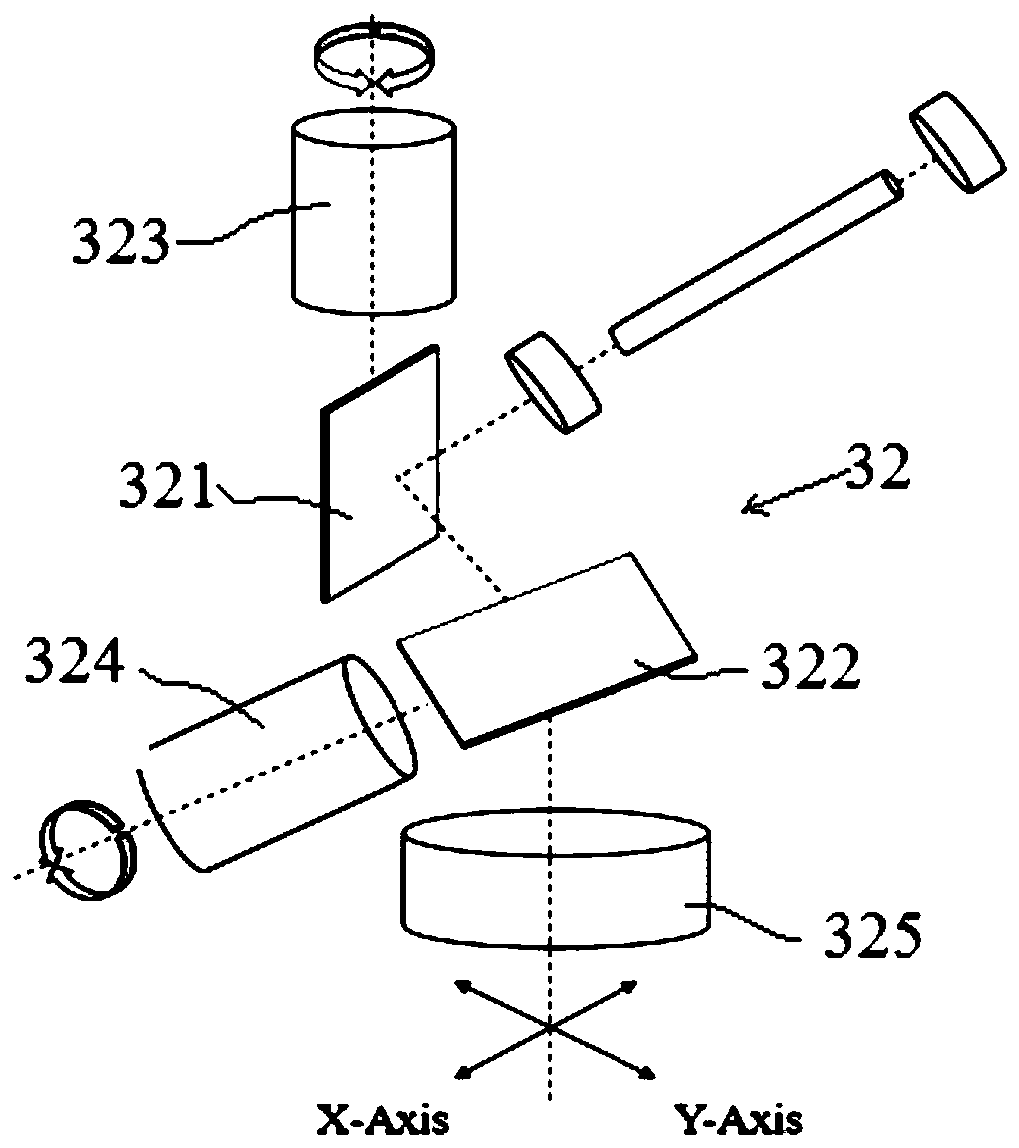

[0039] In the local heating step S2, the infrared laser is used to generate a linear spot to locally heat the preheated glass substrate, thereby assisting the chemical vapor deposition reaction coating.

[0040] Among them, in the process of local heating of the glass substrate by the infrared laser, a vibrating mirror is used to change the path of the laser beam; the length of the linear spot is 0.5-110mm, and the width is 0.2-0.5mm; and the power density distribution of the linear spot satisfies

[0041] h×A×ρ×C×Δt=E / η=P×t

[0042] Among them, h represents the heating depth, A represents the heating area, ρ represents the density of the glass substrate, C represents the specific heat of the glass substrate, Δt represents the temperature rise, E represents the laser he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com