Preparation method of Micro-LED light emitting display device

A light-emitting display device and device technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of reducing the size of soldered chips, prone to false soldering, and low yield rate, and achieves reduction in soldering size, Efficiency and yield rate improvement, the effect of high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

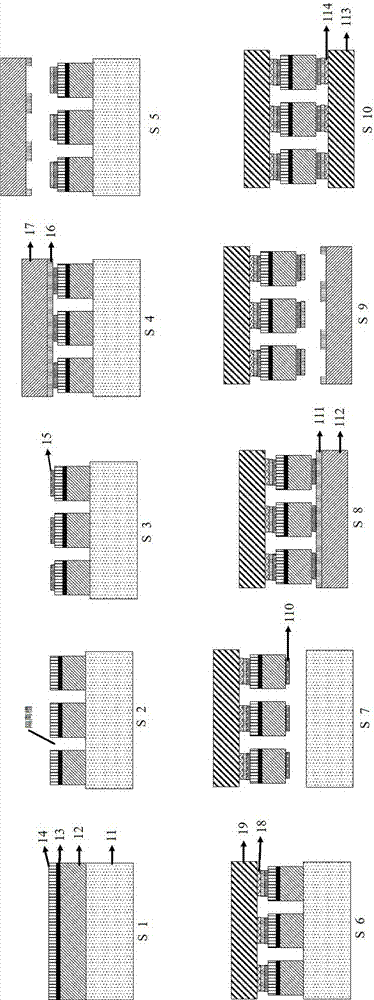

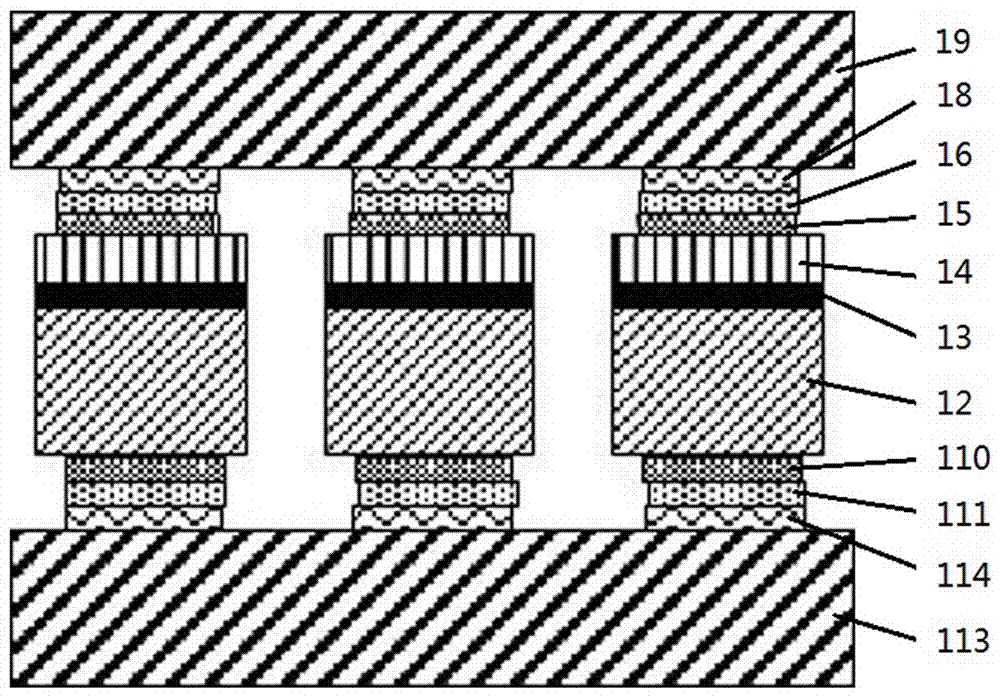

[0031] like figure 1 As shown, a method for preparing a Micro-LED light-emitting display device includes:

[0032] S1: Deposit an n-type GaN epitaxial layer 12, a multi-quantum well layer 13, and a p-type GaN epitaxial layer 14 on the clean GaN substrate 11 from bottom to top;

[0033] S2: Use photolithography and etching to form isolation grooves on the deposited n-type GaN epitaxial layer 12, multi-quantum well layer 13 and p-type GaN epitaxial layer 14 to form a Micro-LED unit device array containing multiple unit devices ;

[0034] S3: making a p-type ohmic contact layer 15 on the p-type GaN epitaxial layer 14 of each unit device in the Micro-LED unit device array;

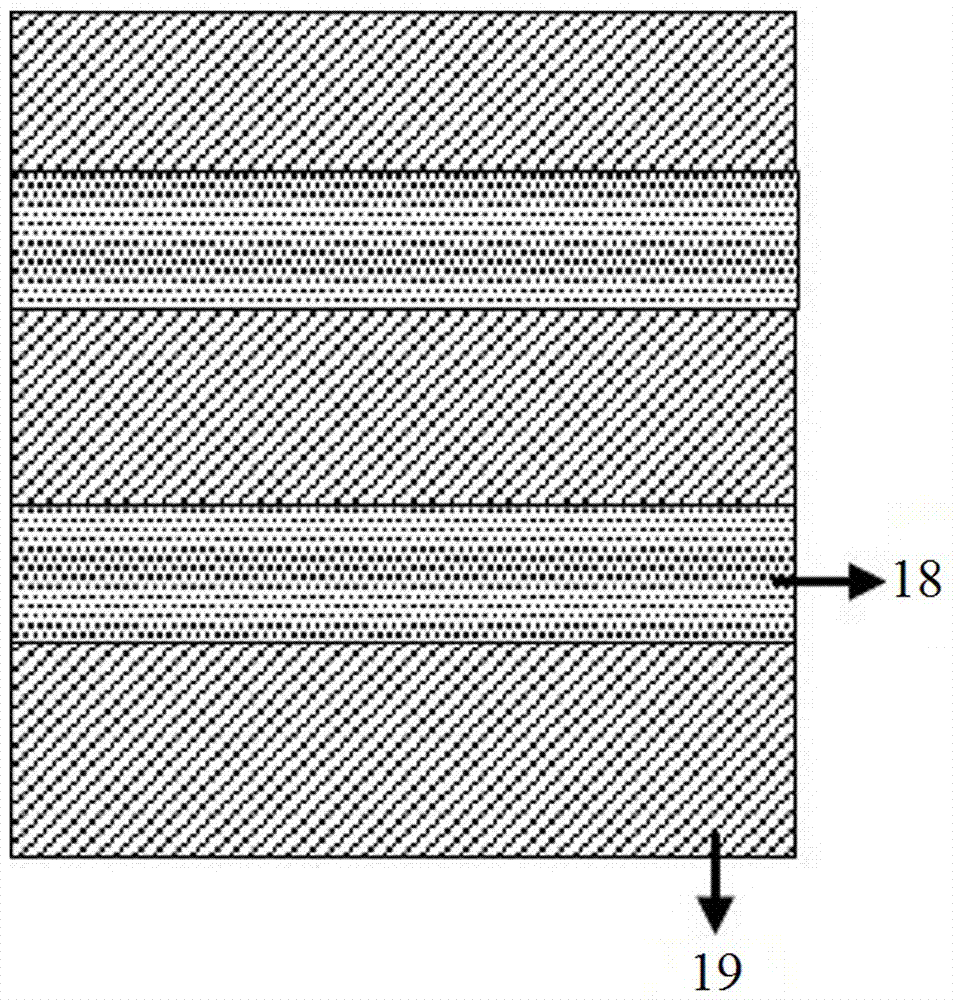

[0035] S4: Evenly coat a layer of conductive paste on the surface of a clean first template 17, and place the p-type ohmic contact layer 15 of the Micro-LED unit device array on the conductive paste, that is, the conductive paste of the first template 17 The paste is in contact with the p-type ohmic contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com