Oxidized-starch-based composite stabilizer and preparation method and application thereof

A compound stabilizer and oxidized starch technology, which is applied in the fields of application, dairy products, and milk preparations, etc., can solve the problems of yogurt texture differences, yogurt texture hardening, yogurt texture roughness, etc., to improve health care efficacy, Less whey precipitation, delicate and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

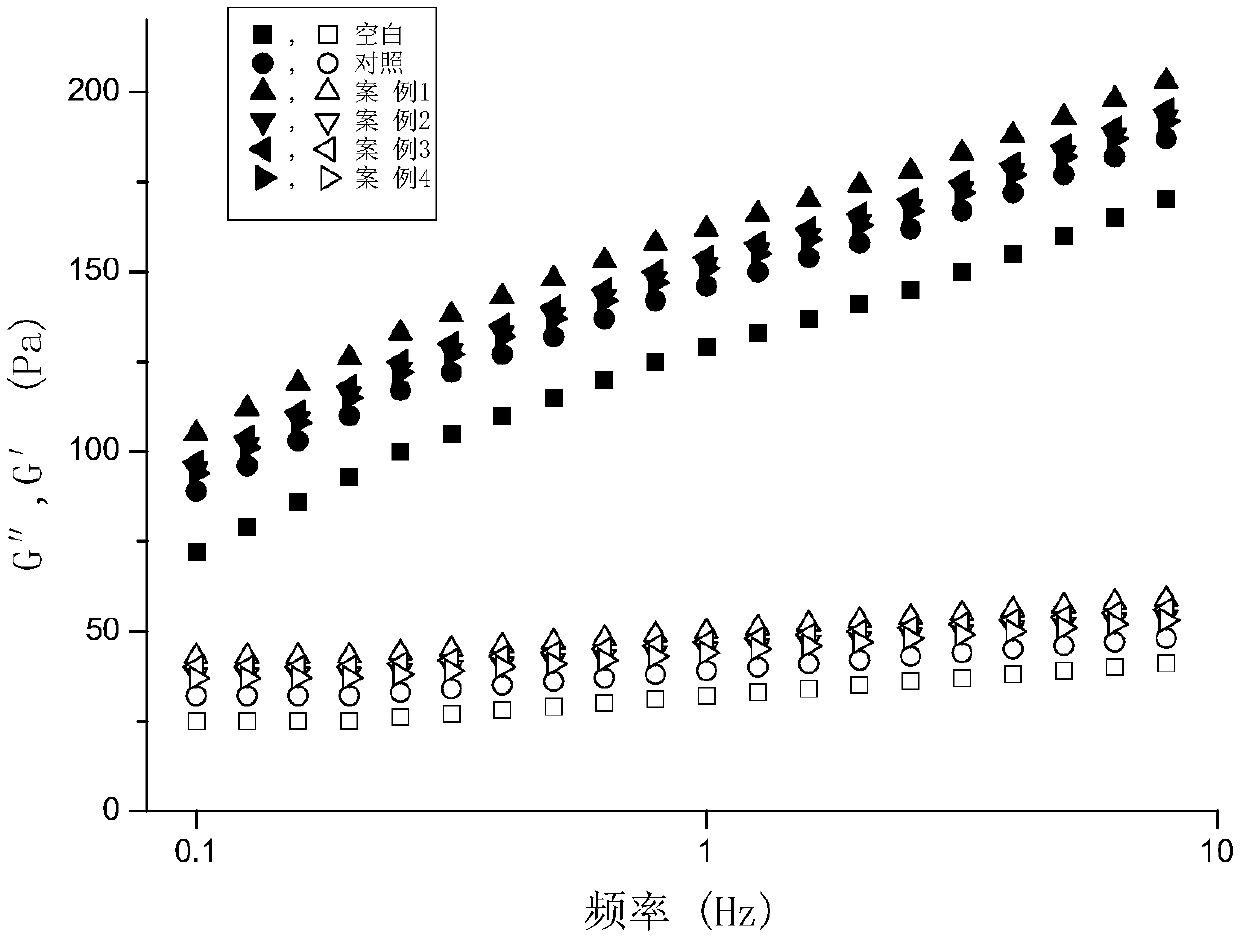

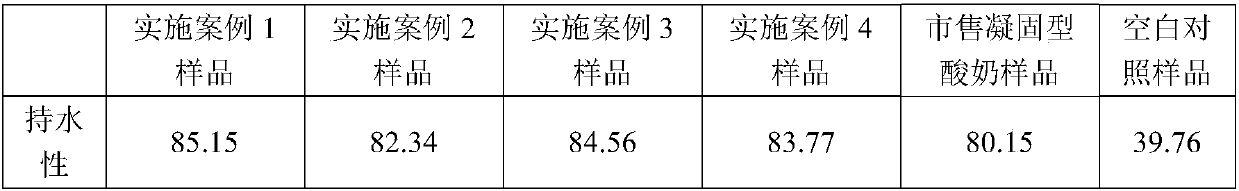

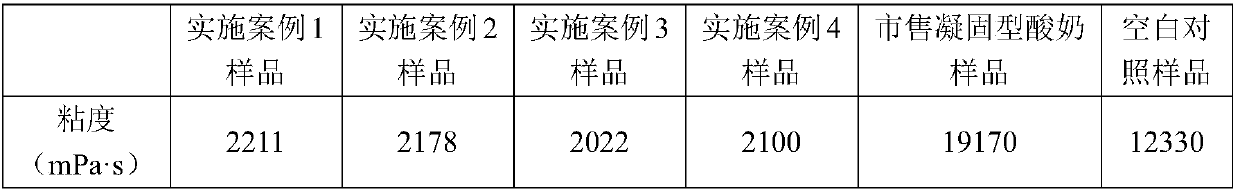

Examples

Embodiment example 1

[0027] (1) Preparation of oxidized starch

[0028] Prepare the starch into starch emulsion with double distilled water, stir it evenly, heat it in a water bath to 35°C, use 0.5mol / L NaOH to adjust the pH of the starch milk to 9.5, and add the sodium hypochlorite solution with an active chlorine concentration of 2% drop by drop Add it to the starch milk, and the dropwise addition should be completed within 30 minutes. After the dropwise addition, the oxidation reaction will be until there is no active chlorine residue. During this period, 1mol / L NaOH is used to maintain the pH value of the starch milk at 9.5. After the oxidation reaction is tested by the starch potassium iodide test paper, use Adjust the pH of starch milk to 7 with 1mol / L HCl, let it stand for 20 minutes, filter, wash, dry, and pulverize to obtain oxidized starch.

[0029] (2) Compounding of stabilizer

[0030] The formula of the set type yogurt stabilizer described in this embodiment is as follows (in w / w%): ...

Embodiment example 2

[0036] (1) Preparation of oxidized starch

[0037] The preparation of oxidized starch is the same as embodiment 1.

[0038] (2) Compounding of stabilizer

[0039] The formulation of the solidified yogurt stabilizer described in this embodiment is as follows (in w / w%): oxidized starch 60%, xanthan gum 25%, agar 15%.

[0040] (3) Preparation of solidified yogurt stabilizer

[0041] When preparing yoghurt with above-mentioned oxidized starch as stabilizer, its formula is as follows (in w / w%): whole milk powder 12%, sucrose 6%, compound stabilizer 1.3%, leavening agent 0.33%, water is 80.37%. Carry out fermentation calculation with 300g milk liquid, the quality of above formula is: whole milk powder 36g, sucrose 18g, composite stabilizer 3.9g (comprising oxidized starch 60%, xanthan gum 25%, agar 15%), leavening agent 1g, water It is 241.1 mL.

[0042] The preparation procedure is:

[0043] Dissolve oxidized starch, xanthan gum, agar, and sucrose in water at 70°C, stir well t...

Embodiment example 3

[0045] (1) Preparation of oxidized starch

[0046]Prepare the starch into starch emulsion with double distilled water, stir it evenly, heat it in a water bath to 35°C, use 0.5mol / L NaOH to adjust the pH of the starch milk to 9.5, and add the sodium hypochlorite solution with an active chlorine concentration of 3% drop by drop Add it to the starch milk, and the dropwise addition should be completed within 30 minutes. After the dropwise addition, the oxidation reaction will be until there is no active chlorine residue. During this period, 1mol / L NaOH is used to maintain the pH value of the starch milk at 9.5. After the oxidation reaction is tested by the starch potassium iodide test paper, use Adjust the pH of starch milk to 7 with 1mol / L HCl, let it stand for 20 minutes, filter, wash, dry, and pulverize to obtain oxidized starch.

[0047] (2) Compounding of stabilizer

[0048] The formula of the set type yogurt stabilizer described in this embodiment is as follows (in w / w%): 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com