Monolithic molecular sieve adsorbent and preparation method and application thereof

A molecular sieve and monolithic technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as low safety, poor adsorption efficiency, and plugging holes, and achieve simple production process, improved adsorption efficiency, and high adsorption efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

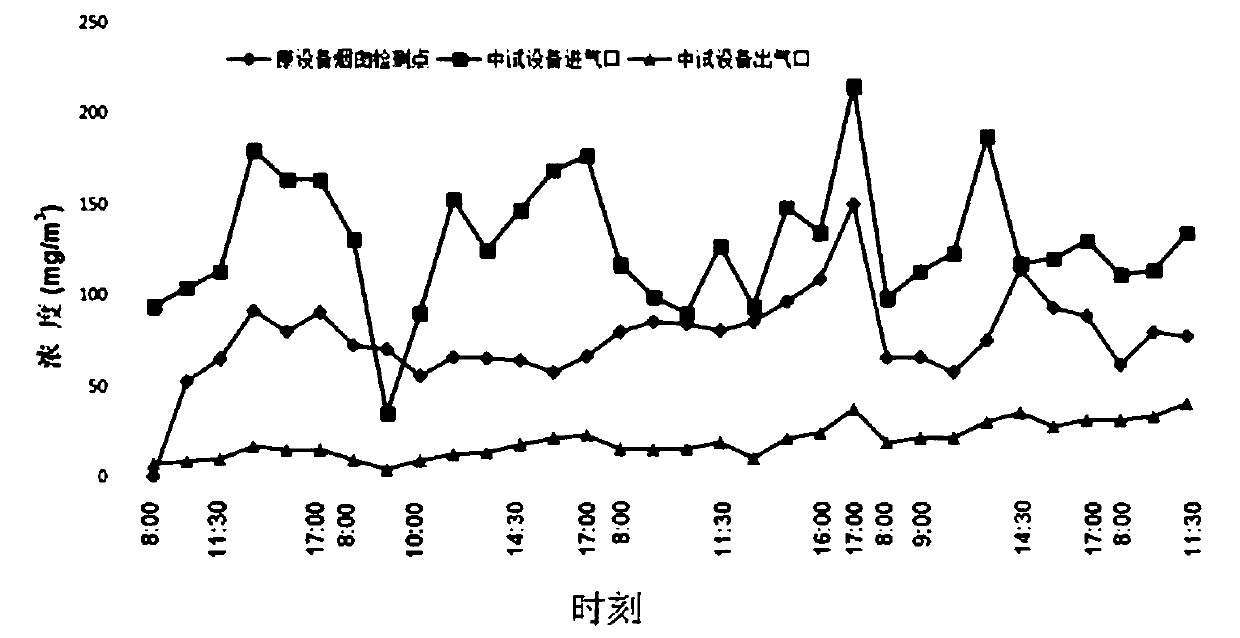

Image

Examples

Embodiment 1

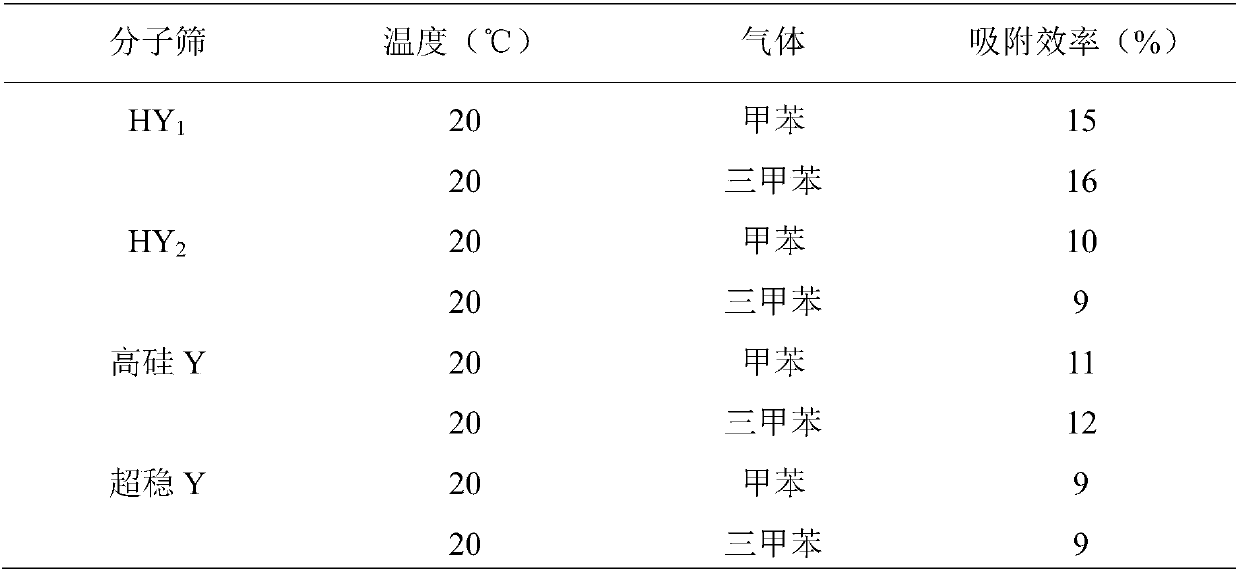

[0029] Choose different types of Y-type molecular sieves, namely HY 1 、HY 2 , high-silicon Y, and ultra-stable Y molecular sieves, compressing and sieving the molecular sieve powders to obtain granular molecular sieves. The various granular molecular sieves obtained were used in the adsorption experiments of benzene series pollutants, and toluene and trimethylbenzene were selected as the representatives of benzene series pollutants to carry out the adsorption experiments respectively.

[0030] The adsorption experiment conditions are as follows: the concentrations of toluene and trimethylbenzene are both 1000ppm, the flow rates are both 100ml / min, and the adsorption is carried out at room temperature. The adsorption results are shown in Table 1.

[0031] Table 1

[0032]

[0033] It can be seen from Table 1 that several Y-type molecular sieves have excellent adsorption capacity for toluene and trimethylbenzene, and their adsorption efficiencies are all above 9%, among wh...

Embodiment 2

[0035] choose HY 1 Molecular sieves are used as adsorbents to prepare monolithic molecular sieve adsorbents. The steps are as follows:

[0036] (1) honeycomb ceramic cordierite (U.S. Corning Company, 400 mesh, 2.5cm 3 ) soaked in deionized water for 24 hours, and dried at 120°C for later use;

[0037] (2) Add high-viscosity zirconium acetate and acetic acid into distilled water, then add HY 1 Molecular sieve powder, use a ball mill to mix each raw material evenly to obtain a coating slurry, and the quality of the high-viscosity zirconium acetate is HY 1 30% of molecular sieve powder quality, the consumption of described acetic acid should make the pH value of coating slurry be 3, the consumption of described distilled water is 45% metering with the solid content of coating slurry;

[0038] (3) Insert one end of the honeycomb cordierite dried in step (1) vertically into the slurry to dip an appropriate amount of coating slurry, and then blow it with an air compressor to even...

Embodiment 3

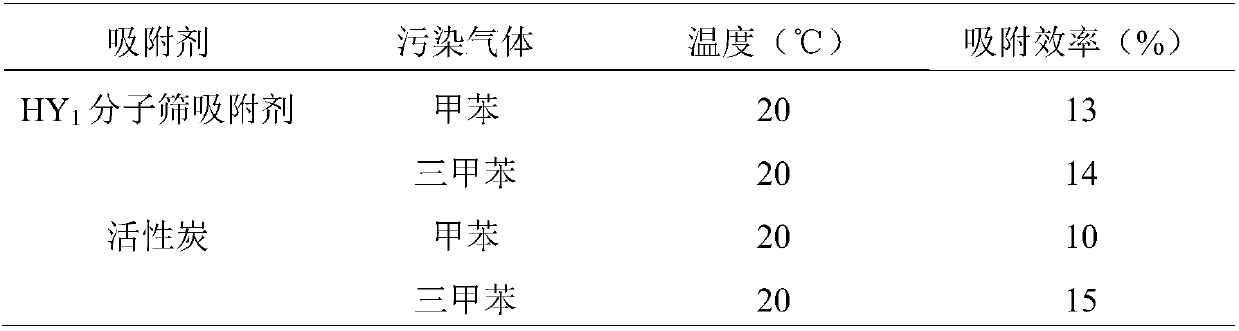

[0045] The monolithic HY in embodiment 2 1 Molecular sieve adsorbent and activated carbon were applied to the adsorption and purification of various VOCs mixed gases, and their desorption efficiency and regeneration performance were investigated. The simulated gas of various VOCs mixtures comes from the volatile gas of a commercial paint thinner, and its composition is shown in Table 3. The experimental conditions of primary adsorption and secondary adsorption are the same as in Example 2; molecular sieve desorption conditions: blowing air at 200° C. for 3 hours. Activated carbon desorption conditions: blowing air at 120°C for 3 hours. The experimental results are shown in Table 4.

[0046] table 3

[0047]

[0048] Table 4

[0049]

[0050] From the experimental results (Table 4), it can be seen that activated carbon has a strong adsorption performance on VOCs mixed gas, and its primary adsorption efficiency is 16%, but its desorption efficiency is only 10%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com