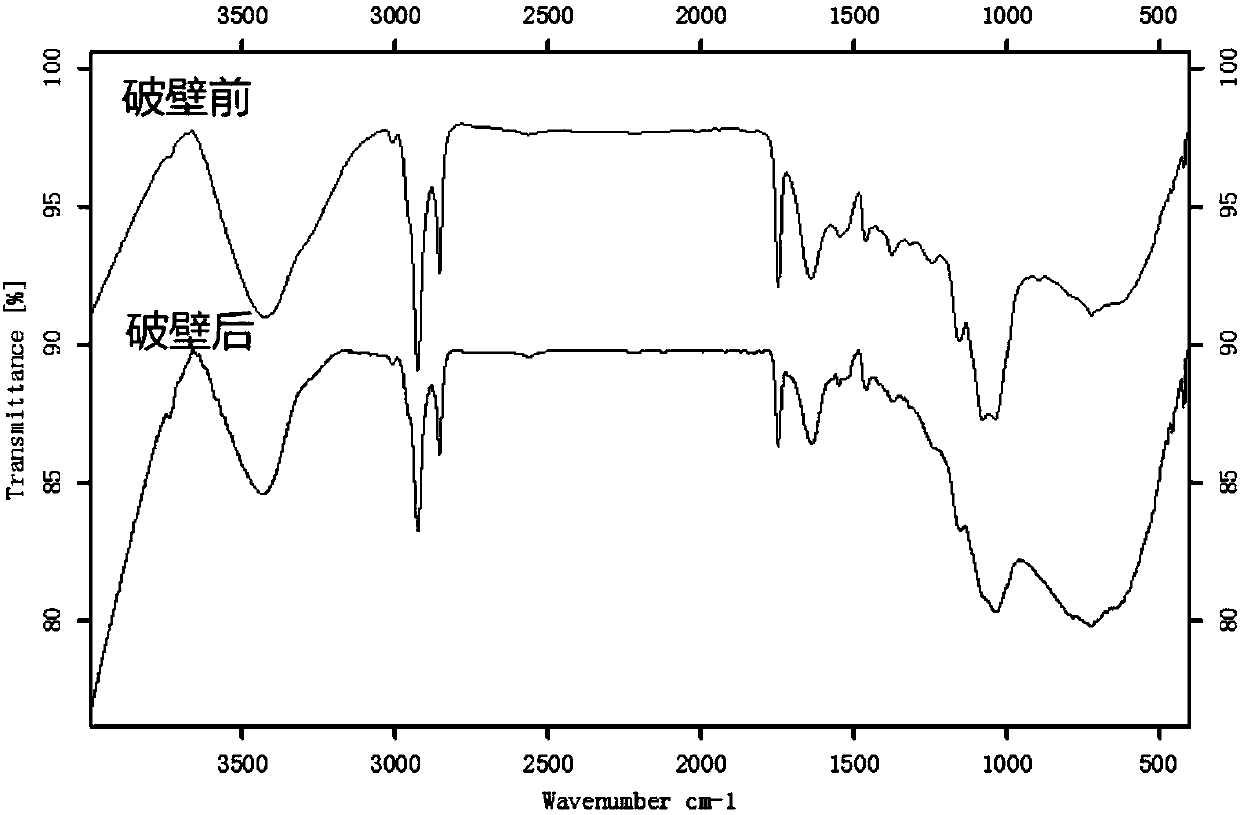

Composite wall breaking treatment method of ganoderma lucidum spore powder

A technology of Ganoderma lucidum spore powder and processing method, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and the dissolution of microorganisms, and can solve the problems of difficult control of the germination conditions of the activated spore germination method, long wall breaking period of the bacterial dissolution method, and poor germination. Deal with problems such as long time to achieve the effect of reducing mechanical impurities and heavy metal pollution, reducing mechanical pollution and heavy metal pollution, and shortening the treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Sterilize 0.2g of Ganoderma lucidum spore powder at 105°C for 30 minutes, keep it warm in a sterilizer for 8 hours, and then dry it.

[0058] 2. Prepare the liquid submerged culture fermentation broth of Ganoderma lucidum mycelium:

[0059] (1) Seed medium: glucose 2g, yeast powder 0.5g, KH 2 PO 4 0.1g, MgSO 4 ·H 2 O 0.1g, water 100mL, pH 6.0.

[0060] (2) Fermentation medium: glucose 15g, yeast powder 7.5g, KH 2 PO 4 1g, MgSO 4 ·H 2 O 0.5g, water 500mL, pH6.0.

[0061] (3) Preparation method: the ganoderma lucidum mycelium was shaken in a seed medium at 25° C. for 3 days, then transferred to a fermentation medium with 15% inoculum size and cultured at 28° C. for 5 days.

[0062] 3. Under aseptic conditions, take 1.2mL of fermentation liquid and add it to 0.2g of sterilized Ganoderma lucidum spore powder, and mix well.

[0063] 4. Incubate statically for 3 days at 25°C in the dark.

[0064] 5. Place the processed spore powder in a freeze dryer for drying. ...

Embodiment 2

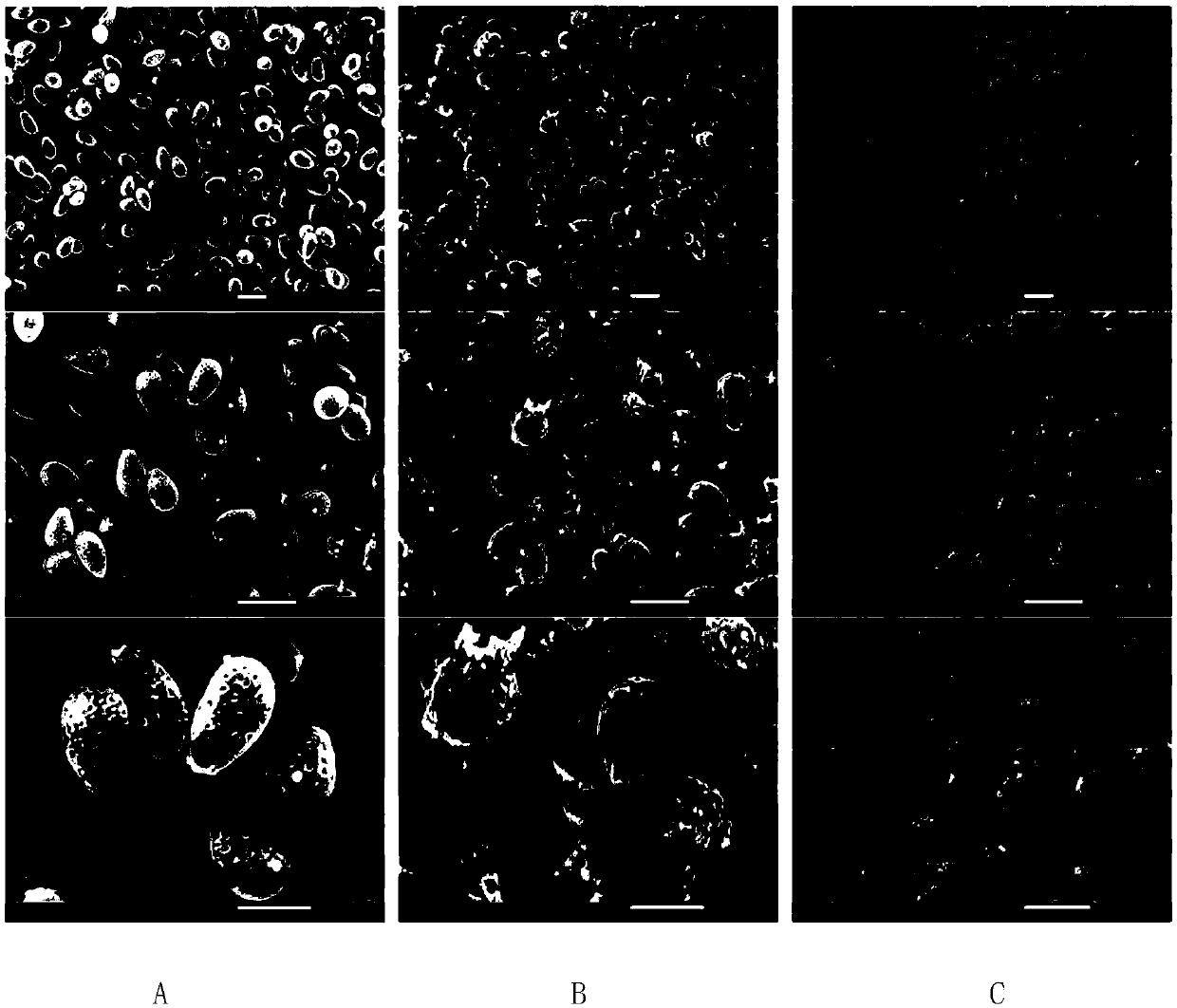

[0079] 1. Sterilize 25g of Ganoderma lucidum spore powder at 105°C for 20 minutes, keep it in a sterilizing pot for 15 hours, and then dry it. Figure 4 (A) shown.

[0080] 2. Prepare the liquid submerged culture fermentation broth of Ganoderma lucidum mycelium:

[0081] (1) Seed medium: glucose 2g, yeast powder 0.5g, KH 2 PO 4 0.1g, MgSO 4 ·H 2 O 0.1g, water 100mL, pH 6.0.

[0082] (2) Fermentation medium: glucose 15g, yeast powder 7.5g, KH 2 PO 4 1g, MgSO 4 ·H 2 O 0.5g, water 500mL, pH6.0.

[0083] (3) Preparation method: the ganoderma lucidum mycelium was shaken in a seed medium at 28° C. for 3 days, then transferred to a fermentation medium with 15% inoculum size and cultured at 25° C. for 5 days.

[0084] 3. Under sterile conditions, take 150ml of fermentation broth and add it to 25g of sterilized Ganoderma lucidum spore powder, mix well, as Figure 4 (B) shown.

[0085] 4. 25°C, constant temperature germination culture under dark conditions for 2 days, such a...

Embodiment 3

[0094] 1. Sterilize 75g of Ganoderma lucidum spore powder at 121°C for 10 minutes, keep it warm in a sterilizer for 8 hours, and then dry it.

[0095] 2. Prepare the liquid submerged culture fermentation broth of Ganoderma lucidum mycelium:

[0096] (1) Seed medium: glucose 1.5g, yeast powder 0.75g, KH 2 PO 4 0.2g, MgSO 4 ·H 2 O 0.1g, water 100mL, pH 5.0.

[0097] (2) Fermentation medium: 500 mL of wort medium of 11 ° Brix, pH natural.

[0098] (3) Preparation method: put the ganoderma lucidum mycelium in the liquid seed culture medium at 26°C

[0099] After shaking for 3 days, transfer to liquid fermentation medium according to 12% inoculum size and culture at 26°C for 4 days.

[0100] 3. Under sterile conditions, take 150ml of fermented broth filtrate and add it to 75g of sterilized Ganoderma lucidum spore powder, and mix well.

[0101] 4. 25°C, constant temperature germination culture in the dark for 2 days.

[0102] 5. Place the treated spore powder in a spray drye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com