Flexible carbon film-coated amorphous Sn-Ni-P sandwich structure nanomaterial and preparation method and application thereof

A nanomaterial and carbon film technology, applied in nanotechnology, nanotechnology, structural parts, etc., can solve the problems of unsatisfactory cycle stability and low specific capacity, and achieve excellent cycle stability performance, high specific capacity, and regular morphology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

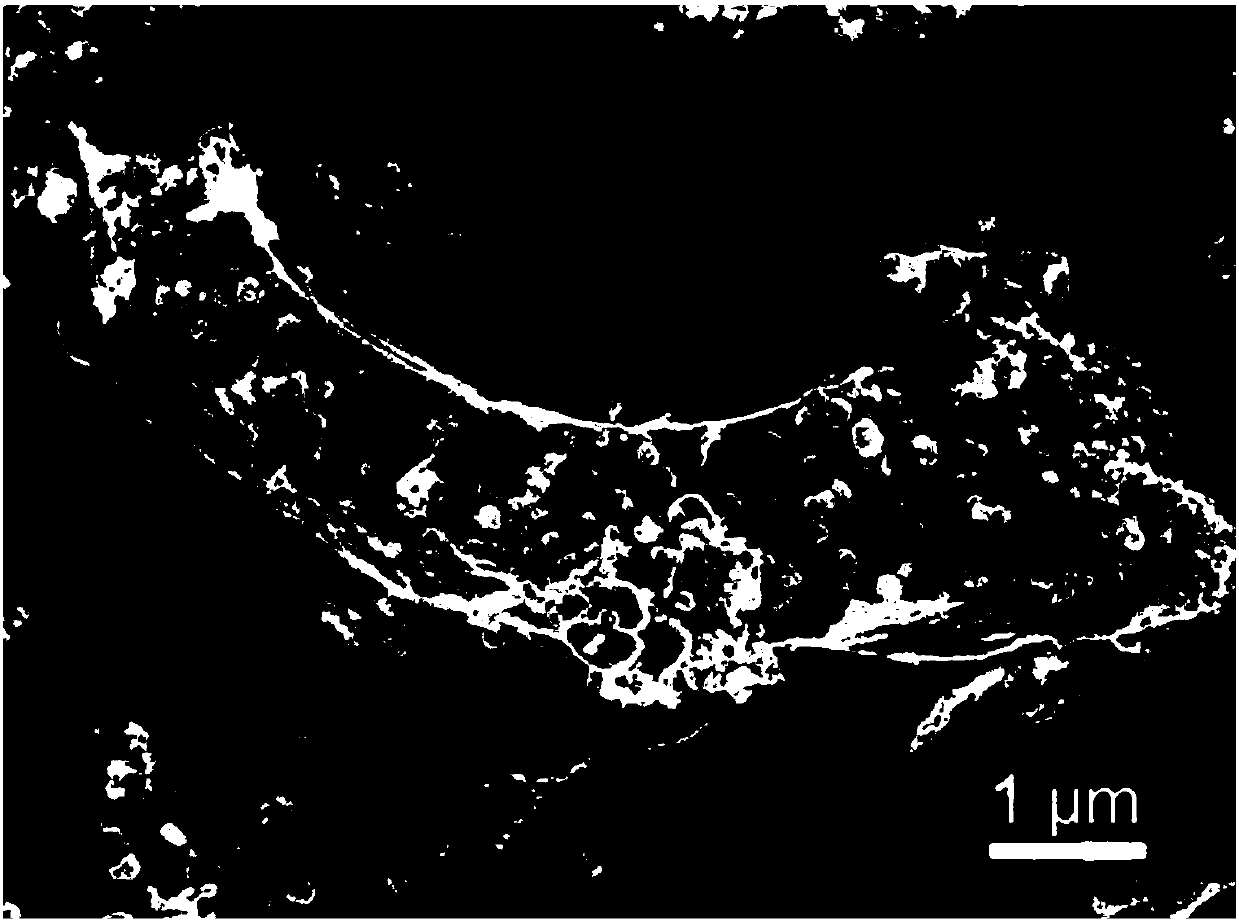

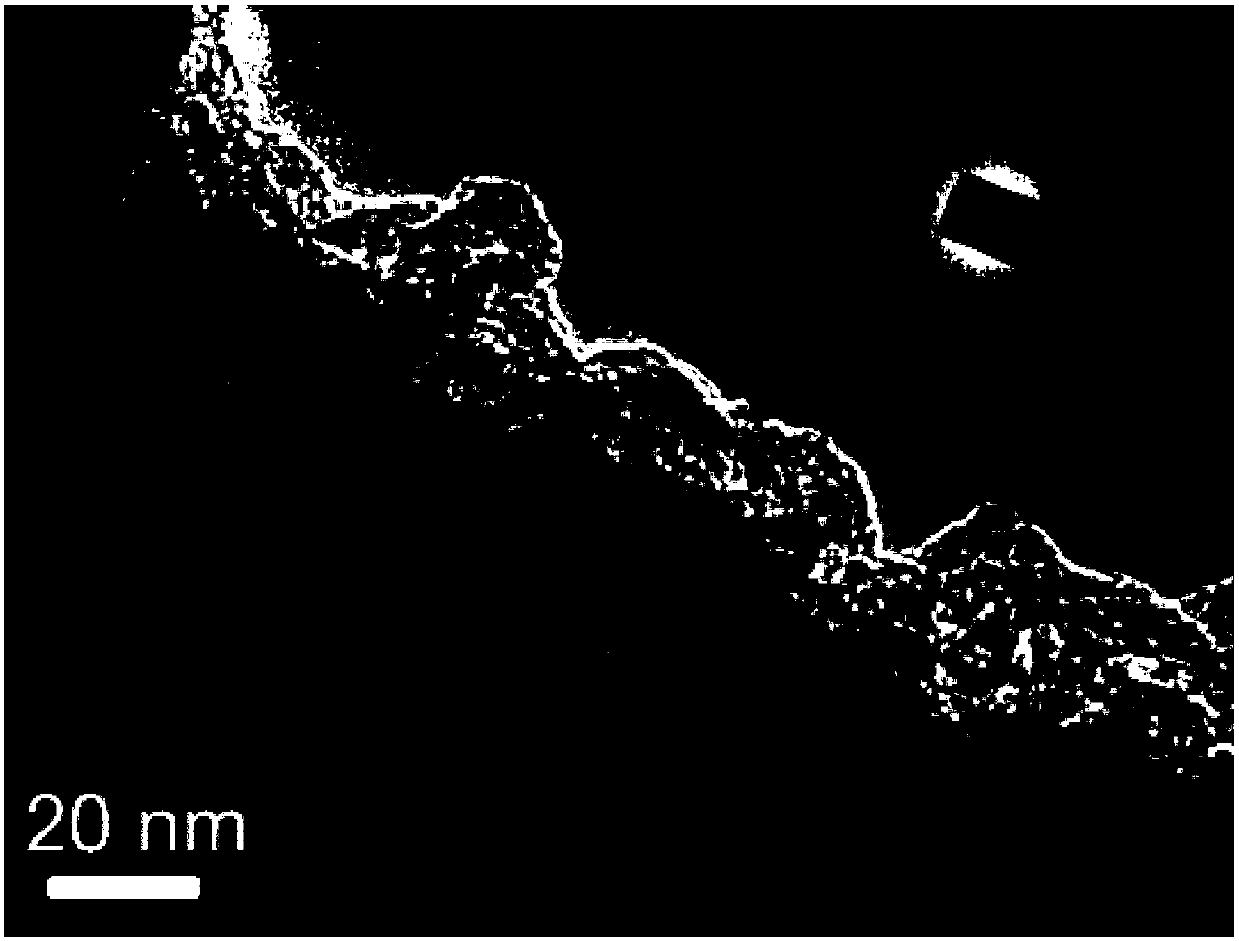

[0034] A kind of preparation method of the Sn-Ni-P structure material that the flexible carbon film of sandwich shape wraps, comprises the following steps:

[0035] 1) Preparation of CS-EDTMP / Sn-Ni composite cyanogel: prepare 2mg / mL acetic acid solution (1wt%) (CS) with dissolved chitosan and 0.2mol / L SnCl 4 Mix the solution, add 0.2mol / L ethylenediaminetetramethylene phosphoric acid (EDTMP) and 0.2mol / L K 2 Ni(CN) 4 The mixed solution, the two solutions are mixed evenly at room temperature and left for a period of time to form a light blue gel;

[0036] 2) Prepare a flexible carbon film-coated Sn-Ni-P material with a sandwich structure: freeze-dry the CS-EDTMP / Sn-Ni composite cyanide rubber prepared in step 1), and dry it at 2K / min under a nitrogen atmosphere. The temperature was raised to 600°C for heat treatment, and kept at this temperature for 2 hours, then cooled, washed and dried by centrifugation to obtain the final product.

Embodiment 2

[0038] A kind of preparation method of the Sn-Ni-P structure material that the flexible carbon film of sandwich shape wraps, comprises the following steps:

[0039] 1) Preparation of CS-EDTMP / Sn-Ni composite cyanogel: prepare 4mg / mL acetic acid solution (1wt%) (CS) with dissolved chitosan and 0.2mol / L SnCl 4 Mix the solution, add 0.2mol / L ethylenediaminetetramethylene phosphoric acid (EDTMP) and 0.2mol / L K 2 Ni(CN) 4 The mixed solution, the two solutions are mixed evenly at room temperature and left for a period of time to form a light blue gel;

[0040] 2) Prepare a flexible carbon film-coated Sn-Ni-P material with a sandwich structure: freeze-dry the CS-EDTMP / Sn-Ni composite cyanide rubber prepared in step 1), and dry it at 2K / min under a nitrogen atmosphere. The temperature was raised to 600°C for heat treatment, and kept at this temperature for 2 hours, then cooled, washed and dried by centrifugation to obtain the final product.

Embodiment 3

[0042] A kind of preparation method of the Sn-Ni-P structure material that the flexible carbon film of sandwich shape wraps, comprises the following steps:

[0043] 1) Preparation of CS-EDTMP / Sn-Ni composite cyanogel: prepare 6mg / mL acetic acid solution (1wt%) (CS) with dissolved chitosan and 0.2mol / L SnCl 4 Mix the solution, add 0.2mol / L ethylenediaminetetramethylene phosphoric acid (EDTMP) and 0.2mol / L K 2 Ni(CN) 4 The mixed solution, the two solutions are mixed evenly at room temperature and left for a period of time to form a light blue gel;

[0044] 2) Prepare a flexible carbon film-coated Sn-Ni-P material with a sandwich structure: freeze-dry the CS-EDTMP / Sn-Ni composite cyanide rubber prepared in step 1), and dry it at 2K / min under a nitrogen atmosphere. The temperature was raised to 600°C for heat treatment, and kept at this temperature for 2 hours, then cooled, washed and dried by centrifugation to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap