Composite bone cement capable of forming pores and increasing the holding ability of bone, preparation method and applications thereof

A technology of bone cement and pore formation, which is applied in medical science, tissue regeneration, prosthesis, etc., and can solve the problems of limited effect, ineffective effect, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

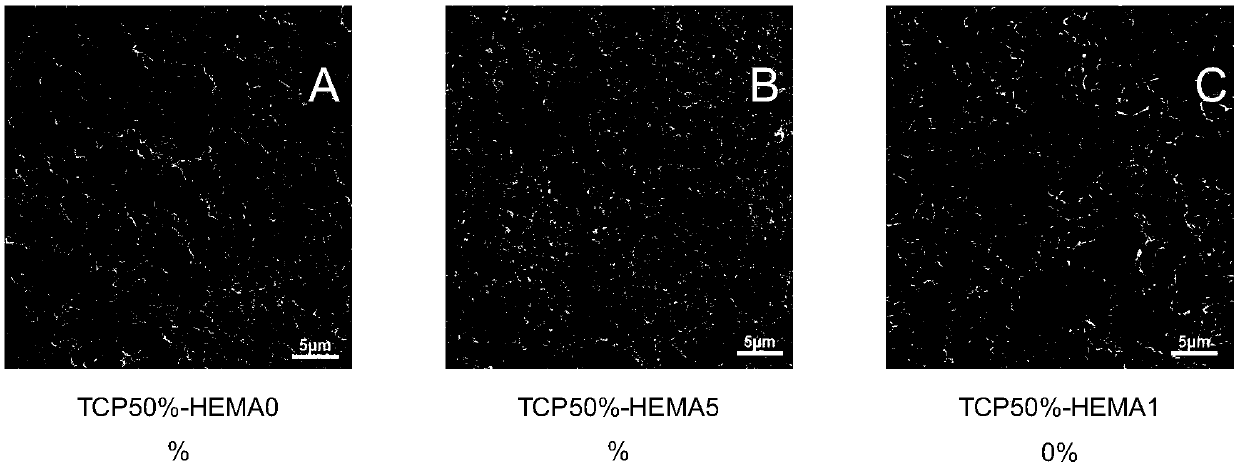

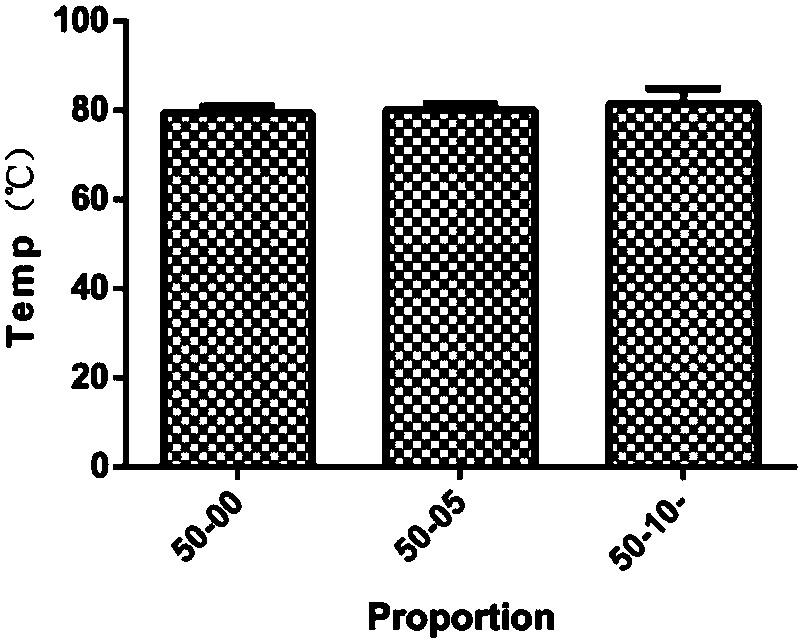

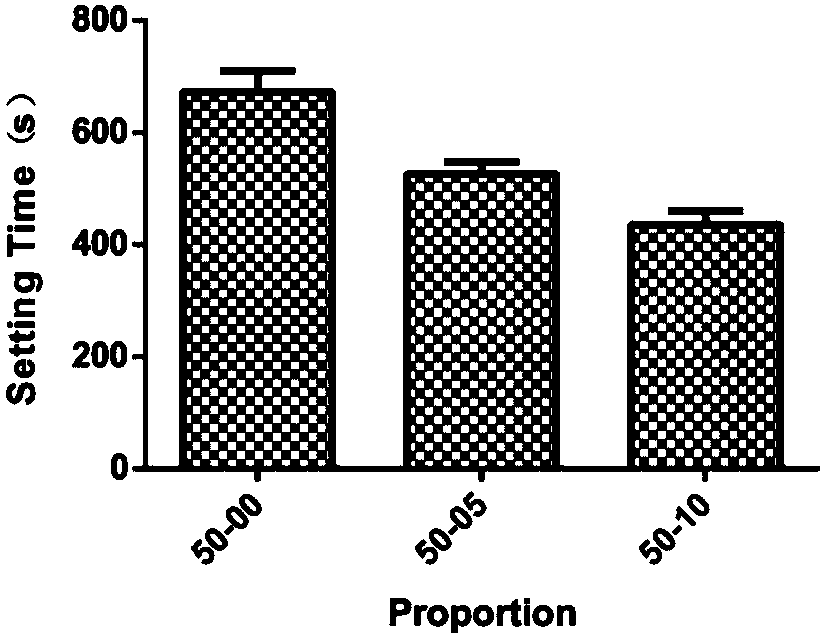

[0053] Preparation and characterization of bone cement C1 containing 50% β-tricalcium phosphate (TCP) in solid phase and 5% HEMA in liquid phase

[0054] 1. Prepare the mixing system for forming composite bone cement C1:

[0055] 1) Prepare the solid phase components in the system: mix 5g of PMMA powder currently used clinically (Tianjin Synthetic Materials Industry Research Co., Ltd.) and 5g of TCP powder (β-tricalcium phosphate, Nanjing Epurui Nano Materials Co., Ltd. company) were mixed and loaded into a ball mill jar, and mixed at a low speed for 30 minutes to obtain a solid phase component.

[0056] 2) Prepare the liquid phase components in the system: Methyl methacrylate with a mass fraction of 94.55%, HEMA with a mass fraction of 5%, and DMPT with a mass fraction of 0.45% are mixed to prepare a liquid phase component.

[0057] 2. Preparation of composite bone cement C1:

[0058] Weigh 8g of the solid phase component into a 20ml syringe, add the liquid phase component,...

Embodiment 2

[0066] Preparation and characterization of bone cement C2 containing 50% β-tricalcium phosphate (TCP) in solid phase and 10% HEMA in liquid phase

[0067] 1. Prepare the mixing system for forming composite bone cement C2:

[0068] 1) Prepare the solid phase components in the system: mix 5g of PMMA powder currently used clinically (Tianjin Synthetic Materials Industry Research Co., Ltd.) and 5g of TCP powder (β-tricalcium phosphate, Nanjing Epurui Nano Materials Co., Ltd. company) were mixed and loaded into a ball mill jar, and mixed at a low speed for 30 minutes to obtain a solid phase component.

[0069] 2) Prepare the liquid phase components in the system: 89.55% methyl methacrylate and 10% HEMA are mixed with 0.45% DMPT to prepare the liquid phase components.

[0070] 2. Preparation of composite bone cement C2:

[0071] Weigh 8g of the solid phase component into a 20ml syringe, add the liquid phase component, control the solid-liquid ratio to 2:1 (g / mL), stir well for 1mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com