Wet-process and dry-process combined flue gas desulfurization system and desulfurization method

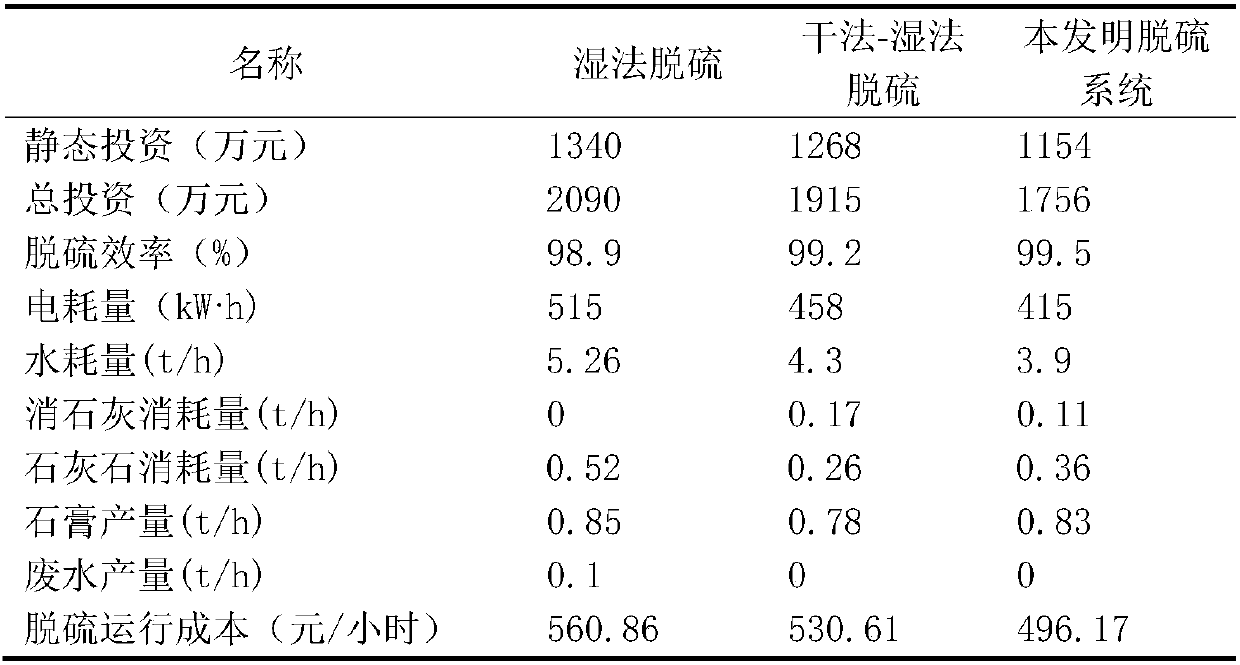

A desulfurization system and wet desulfurization technology, applied in the desulfurization system and desulfurization field combined wet and dry, can solve the problems of difficult aerosol diffusion, high humidity of exhaust flue gas, high investment cost, and reduce the amount of treated flue gas. , Eliminate environmental problems and reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

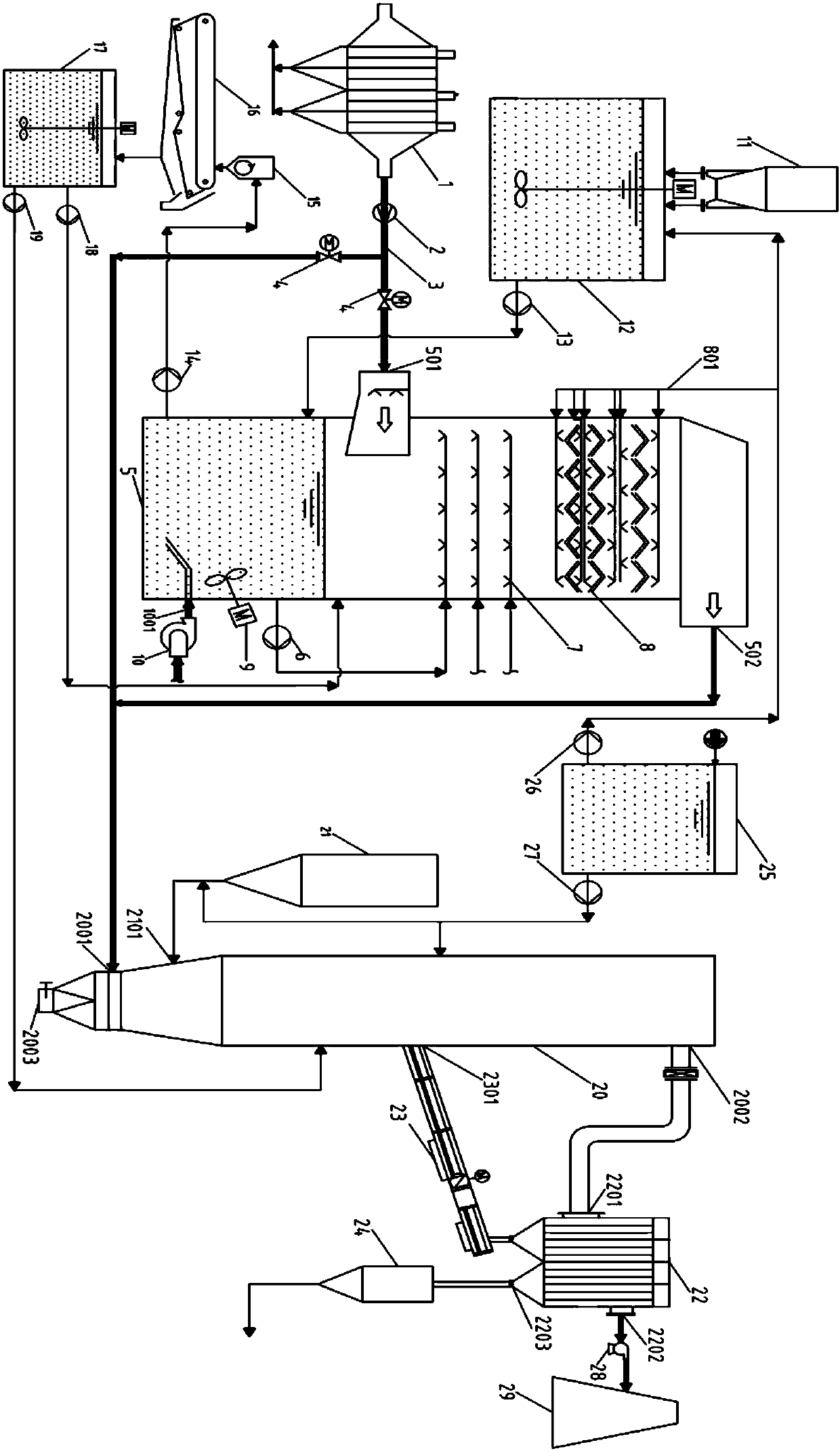

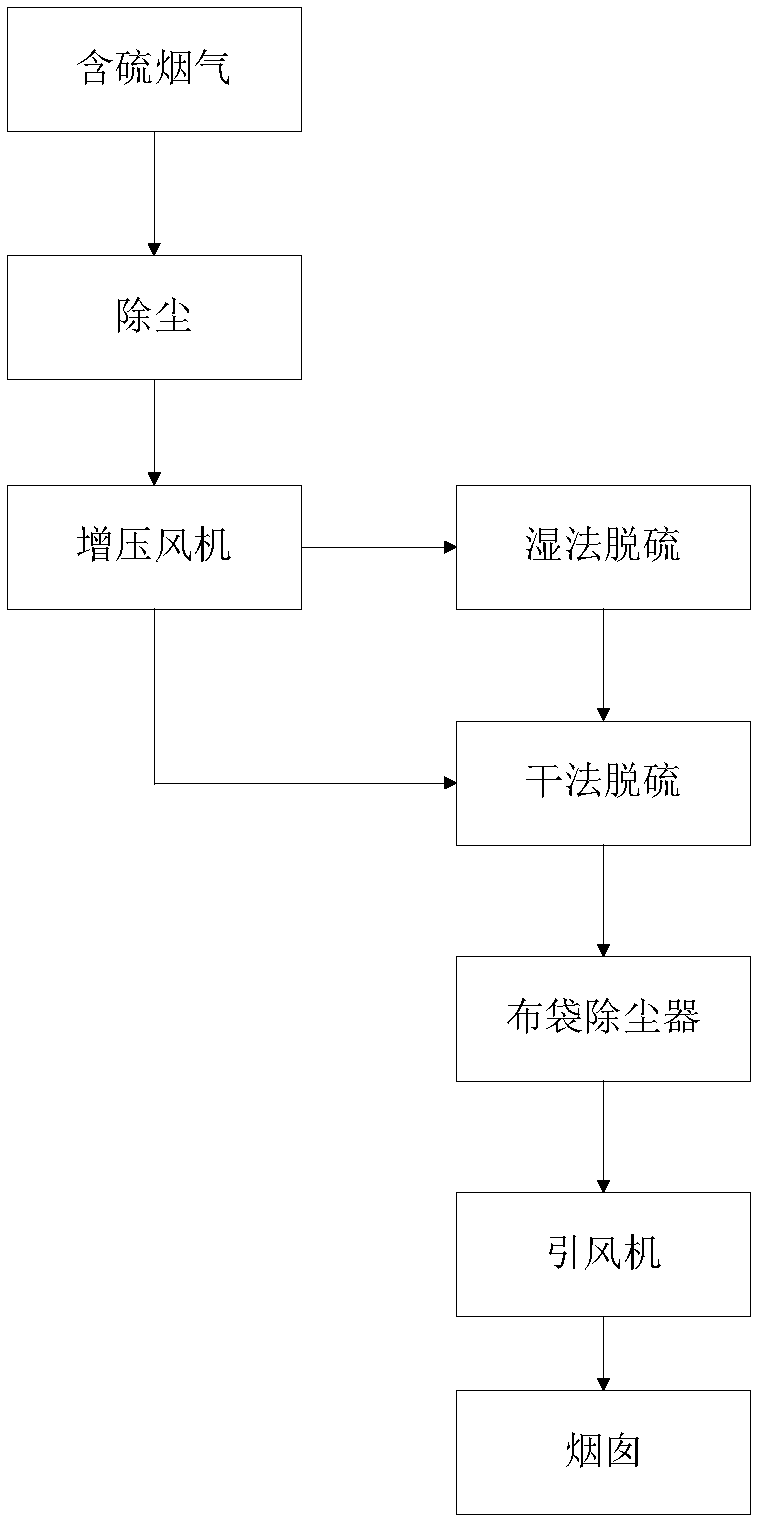

[0019] Such as figure 1 As shown, the combined wet and dry flue gas desulfurization system of the present invention is composed of a dust removal booster system, a wet desulfurization system and a dry desulfurization system. The dust removal system includes dust collector 1, booster fan 2, flue gas inlet pipe 3 and regulating valve 4; the wet desulfurization system includes wet absorption tower 5, slurry circulation pump 6, slurry spray layer 7, demister 8, slurry Agitator 9, oxidation fan 10, limestone powder bin 11, slurry tank 12, slurry supply pump 13, slurry discharge pump 14, cyclone separator 15, vacuum belt dehydrator 16, return water tank 17, return water pump 18 and waste water pump 19 The dry desulfurization system includes a dry absorption tower 20, a slaked lime bin 21, a bag filter 22, a feeder 23, a desulfurization ash bin 24, a process water tank 25, a demister flushing water pump 26 and a process water pump 27.

[0020]The outlet of the dust collector 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com