Welding wire for 630 MPa grade high Nb steel double submerged arc welding

A technology of submerged arc welding and welding wire, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems that the strength and toughness of the weld seam are difficult to meet the requirements, and achieve the improvement of insufficient strength and toughness and high weld toughness , excellent economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

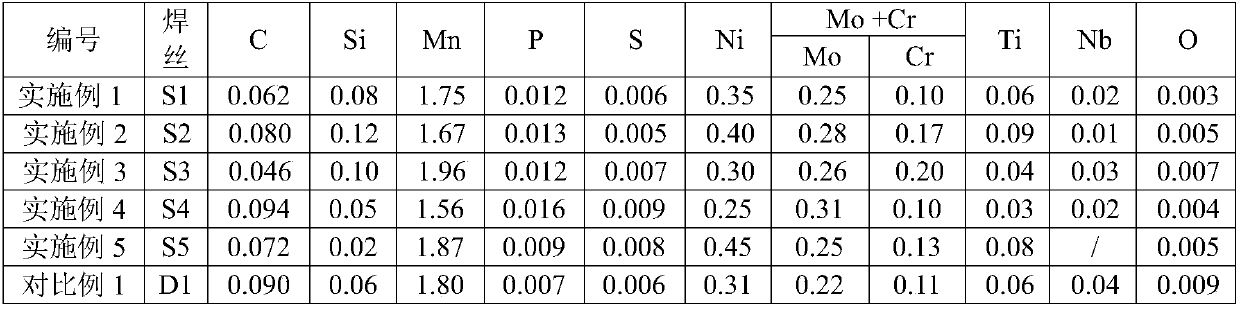

[0033] The chemical composition of the welding wire used for double-pass submerged arc welding of 630MPa high Nb steel described in Examples 1 to 5 is shown in Table 1 respectively, and the main preparation steps are as follows:

[0034] 1) Steel is smelted in a vacuum smelting furnace, refined in an 1F furnace or an Ar station, so that the chemical composition of the steel meets the composition design requirements, and then continuously cast into billets to increase the proportion of equiaxed crystals of the billet as much as possible;

[0035] 2) The billet is rolled into wire rod, pay attention to slowly heating the billet; the obtained wire rod is made into finished welding wire through pickling, cleaning, drying, wire drawing, cleaning, copper plating and other processes, and the diameter of the welding wire is 4.0mm.

[0036] Table 1 Embodiment 1~5 gained welding wire chemical composition (wt%)

[0037]

[0038] Note: Als≤0.02wt%.

[0039] The welding wires S1-5 obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com