Method for removing bromates from water by homogeneous photocatalysis

A bromate and water removal technology, used in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem of poor stability of ferrous ions and zero-valent iron, limited adsorption capacity of activated carbon, and large ultraviolet radiation dose. and other problems, to achieve the effect of strong water quality applicability, strong feasibility and operability, and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

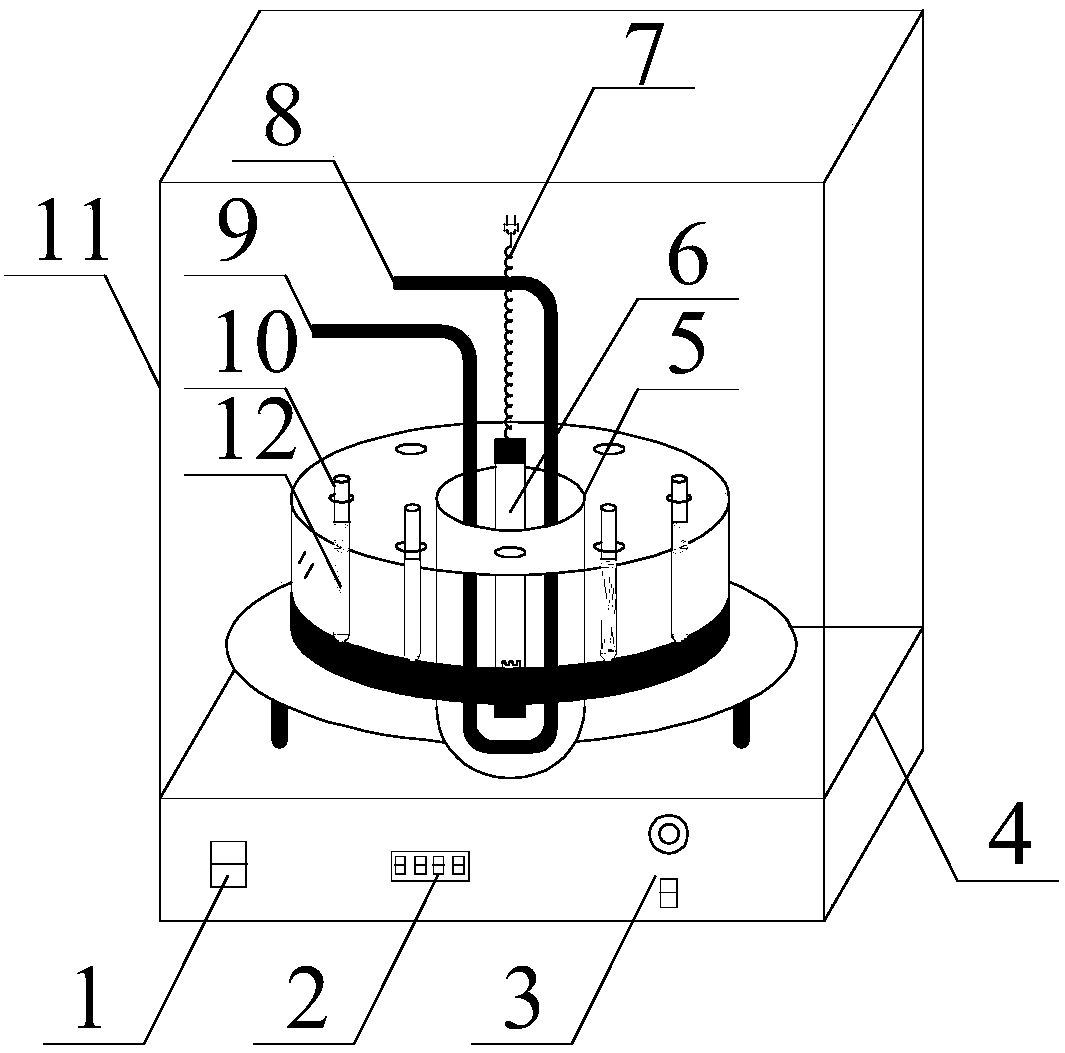

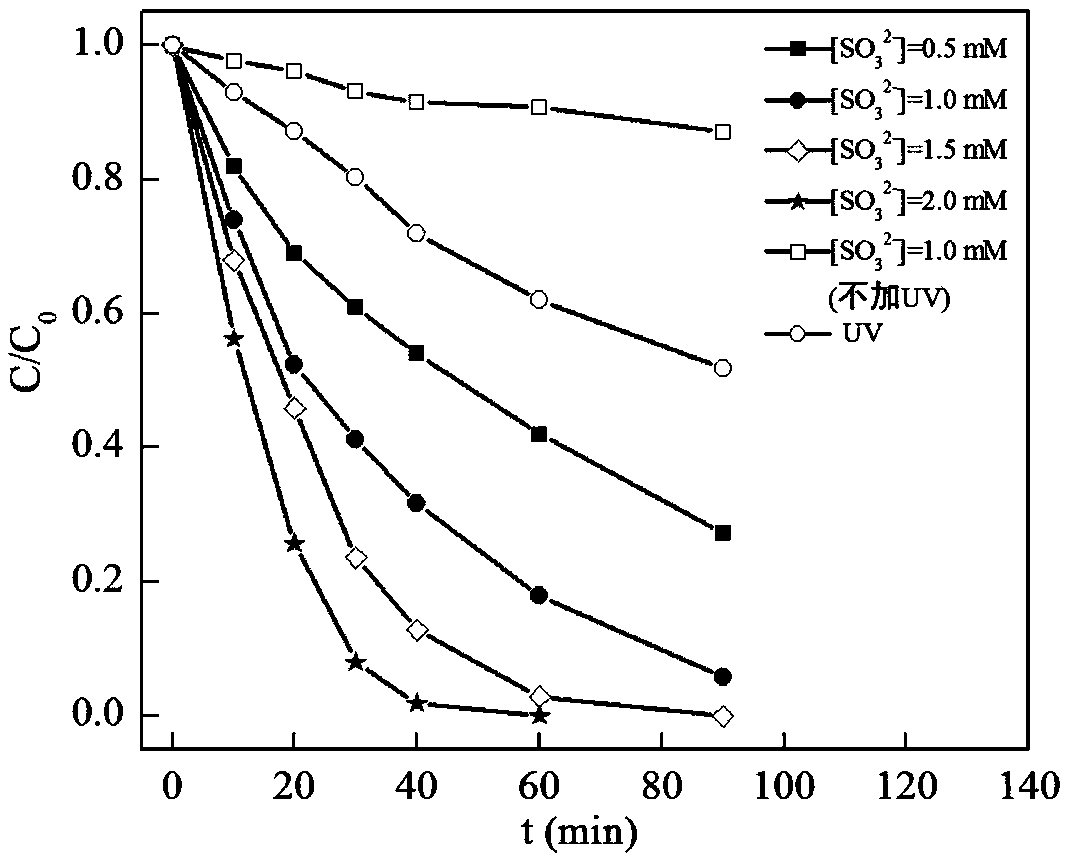

[0041] 1.0mol / L sodium sulfite solution and 0.1mmol / L bromate solution were prepared in advance with distilled water, and both sodium sulfite solution and bromate solution were prepared on the same day.

[0042] The cooling water in the quartz well is constantly exchanged by a peristaltic pump, so that the reaction is carried out at a constant temperature of 25±0.5°C; 2 ) to preheat for 20 minutes.

[0043] Add an equal amount of bromate solution to 6 quartz tubes (1#, 2#, 3#, 4#, 5#, 6#) to adjust the initial pH value to 6.8, and the 2# quartz tube uses aluminum foil Seal with paper to make it opaque, then add sodium sulfite solution to 6 quartz tubes at the same time, and control the concentration of sodium sulfite to 0.0mmol / L, 1.0mmol / L, 0.5mmol / L, 1.0mmol / L, 1.5mmol / L and 2.0mmol / L, turn on the device, make the quartz tube rotate around the ultraviolet lamp at a constant speed to ensure uniform radiation of ultraviolet light, and at the same time use a magnetic stirrer t...

Embodiment 2

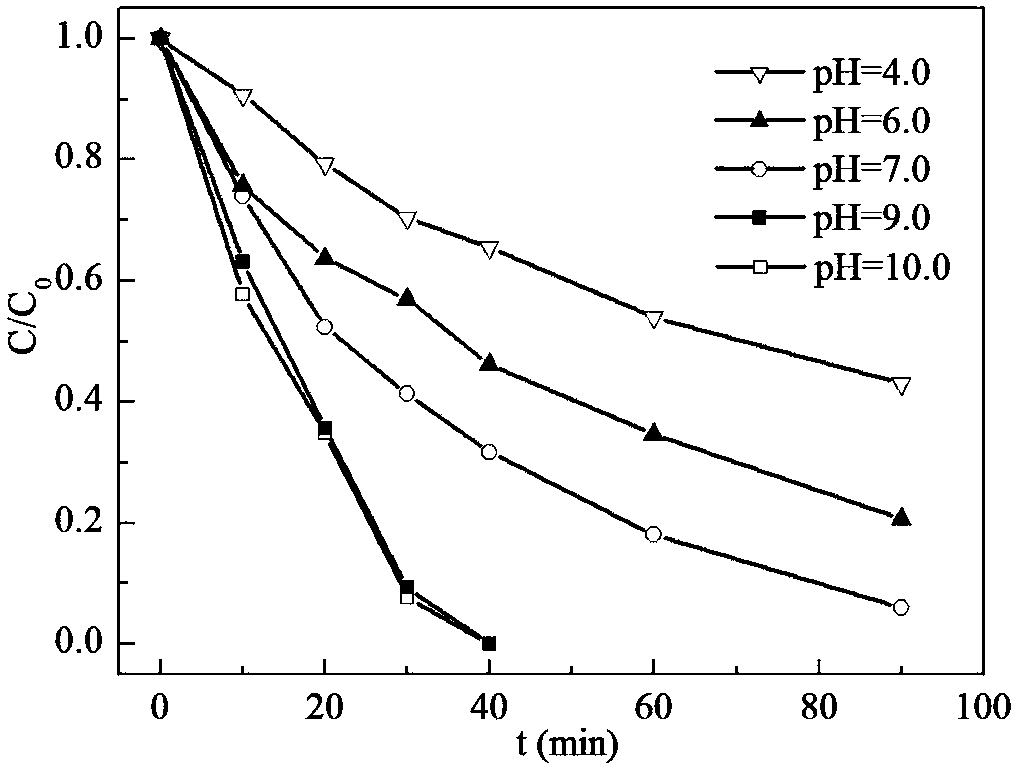

[0048] 1.0mol / L sodium sulfite solution and 0.1mmol / L bromate solution were prepared in advance with distilled water, and both sodium sulfite solution and bromate solution were prepared on the same day.

[0049] The cooling water in the quartz well is constantly exchanged by a peristaltic pump, so that the reaction is carried out at a constant temperature of 25±0.5°C; 2 ) to preheat for 20 minutes.

[0050] Add an equal amount of bromate solution to five quartz tubes, and use 0.1mmol / L NaOH solution and 0.1mmol / L HCl solution to adjust the initial pH value of the system to 4.0, 6.0, 7.0, 9.0 and 10.0, and then add five Add sodium sulfite solution with a concentration of 1.0mmol / L to two quartz tubes at the same time, turn on the device, and make the quartz tube rotate around the ultraviolet lamp at a constant speed to ensure uniform radiation of ultraviolet light. At the same time, use a magnetic stirrer to stir the solution to ensure that the solution is mixed. uniform.

[...

Embodiment 3

[0054] Dithionite solution of 1.0mol / L and bromate solution of 0.1mmol / L were prepared in advance with distilled water, and dithionite solution and bromate solution were prepared on the same day.

[0055] The cooling water in the quartz well is constantly exchanged by a peristaltic pump to keep the reaction constant at 25±0.5°C; 2 ) to preheat for 20 minutes.

[0056] Add an equal amount of bromate solution to 6 quartz tubes (1#, 2#, 3#, 4#, 5#, 6#) to adjust the initial pH value to 6.8, and the 2# quartz tube uses aluminum foil Seal it with paper to make it opaque, then add dithionite to 6 quartz tubes at the same time, and control the concentration of dithionite to 0.0mmol / L, 2.0mmol / L, 1.0mmol / L, respectively. L, 1.5mmol / L, 2.0mmol / L and 2.5mmol / L, turn on the device to make the quartz tube rotate around the UV lamp at a constant speed to ensure uniform radiation of ultraviolet light, and at the same time use a magnetic stirrer to stir the solution to ensure that the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com