Method for preparing concrete air-entraining agent

A technology of air-entraining agent and concrete, which is applied in the field of preparation of concrete air-entraining agent, can solve the problems of complicated processing technology and high production cost, and achieve the effects of simple processing technology, low production cost and improved other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

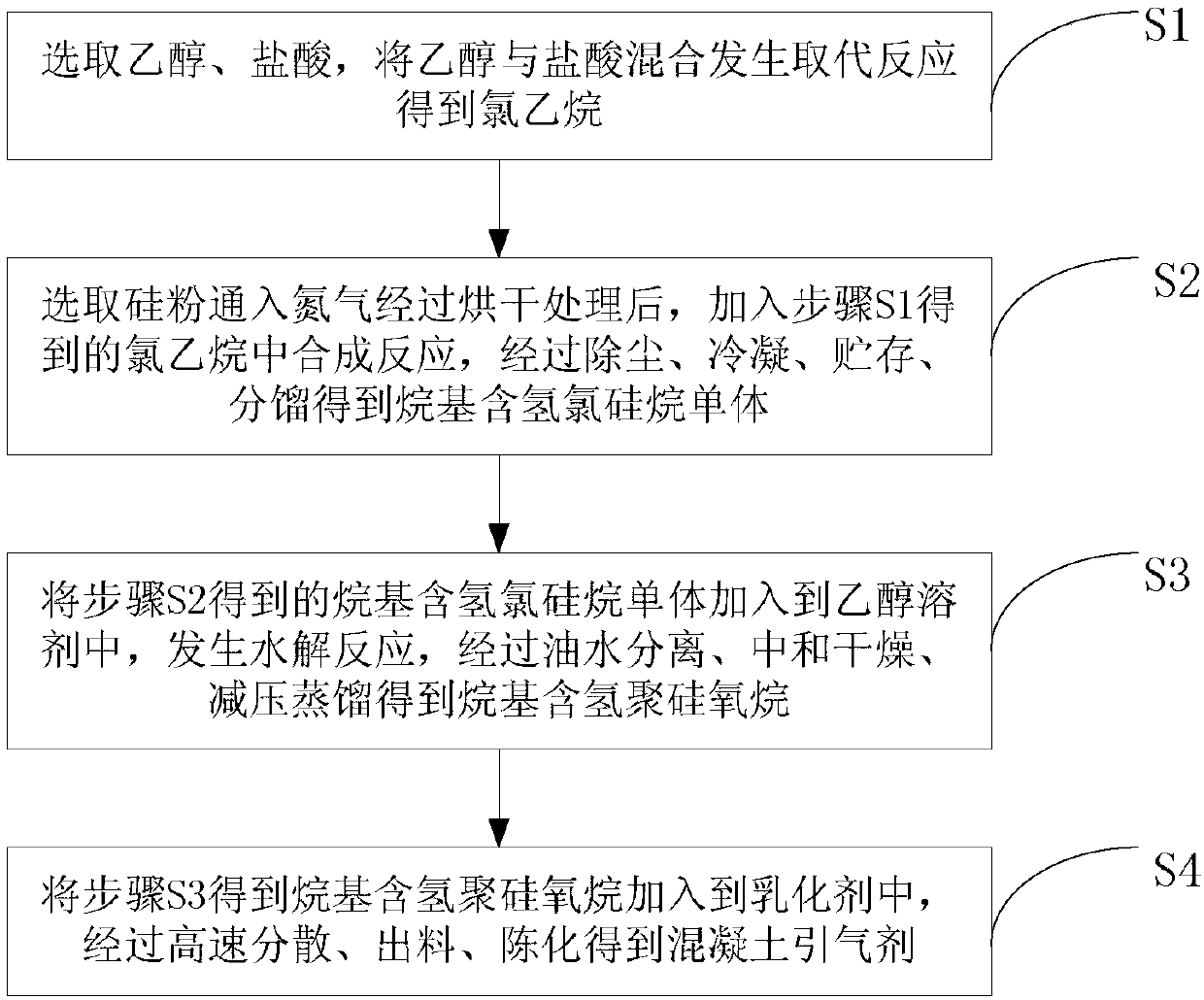

[0023] combine figure 1 , a preparation method of concrete air-entraining agent, comprising the following steps:

[0024] S1, select ethanol, hydrochloric acid, ethanol and hydrochloric acid are mixed to undergo a substitution reaction to obtain ethyl chloride; the molar ratio of ethanol to hydrochloric acid is 1:1;

[0025] S2. After drying the silicon powder and feeding it with nitrogen, add the ethyl chloride obtained in step S1 for a synthesis reaction, and obtain an alkyl hydrochlorosilane monomer through dedusting, condensation, storage and fractionation; the silicon powder is 1200 mesh; The fractional distillation temperature is 70-80°C;

[0026] S3. Add the alkyl hydrogen-containing chlorosilane monomer obtained in step S2 into an ethanol solvent to undergo a hydrolysis reaction, and undergo oil-water separation, neutralization and drying, and vacuum distillation to obtain an alkyl hydrogen-containing polysiloxane; during neutralization and drying Add desiccant;

[...

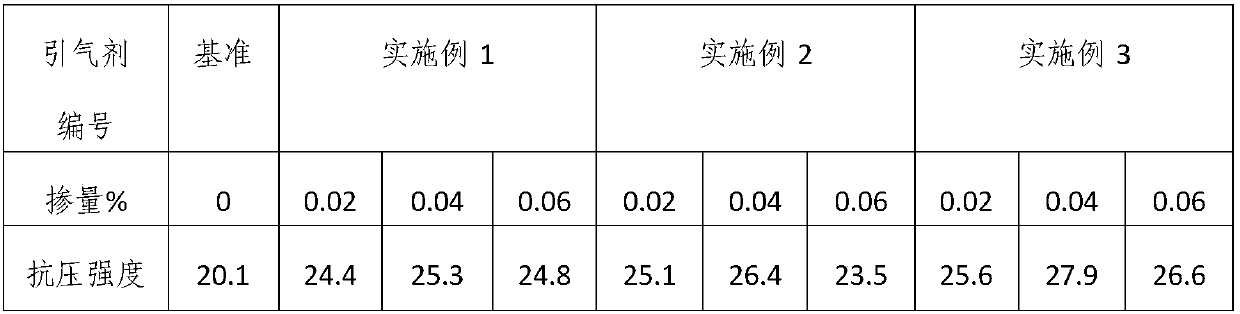

Embodiment 1

[0029] A preparation method for concrete air-entraining agent, comprising the following steps:

[0030] S1, select ethanol and hydrochloric acid according to 1:1, mix ethanol and hydrochloric acid to undergo a substitution reaction to obtain ethyl chloride;

[0031] S2. After drying the silicon powder into nitrogen gas, the silicon powder is 1200 mesh, and then add the ethyl chloride obtained in step S1 for a synthesis reaction, and obtain the alkyl hydrochlorosilane monomer through dedusting, condensation, storage, and fractionation. The fractional distillation temperature is 70°C;

[0032] S3. Add the alkyl hydrogen-containing chlorosilane monomer obtained in step S2 into an ethanol solvent to undergo a hydrolysis reaction. After oil-water separation, neutralization and drying, a desiccant is added during the neutralization and drying, and the alkyl hydrogen-containing polysilane is obtained by distillation under reduced pressure. Silicone;

[0033] S4. Add the alkyl hydro...

Embodiment 2

[0035] A preparation method for concrete air-entraining agent, comprising the following steps:

[0036] S1, select ethanol and hydrochloric acid according to 1:1, mix ethanol and hydrochloric acid to undergo a substitution reaction to obtain ethyl chloride;

[0037] S2. After drying the silicon powder into nitrogen gas, the silicon powder is 1200 mesh, and then add the ethyl chloride obtained in step S1 for a synthesis reaction, and obtain the alkyl hydrochlorosilane monomer through dedusting, condensation, storage, and fractionation. The fractional distillation temperature is 80°C;

[0038] S3. Add the alkyl hydrogen-containing chlorosilane monomer obtained in step S2 into an ethanol solvent to undergo a hydrolysis reaction. After oil-water separation, neutralization and drying, a desiccant is added during the neutralization and drying, and the alkyl hydrogen-containing polysilane is obtained by distillation under reduced pressure. Silicone;

[0039] S4. Add the alkyl hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com