Concrete anti-freezing water reducing agent

A water reducing agent and concrete technology, applied in the field of concrete, can solve problems such as poor frost resistance, and achieve the effects of improving water reduction rate, improving frost resistance effect, and improving freeze-thaw resistance durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

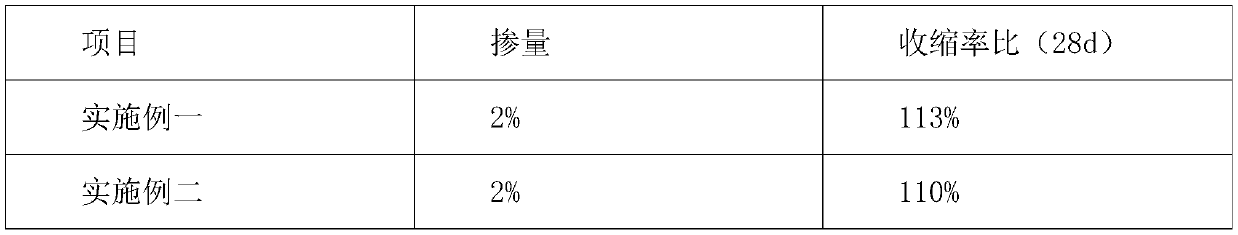

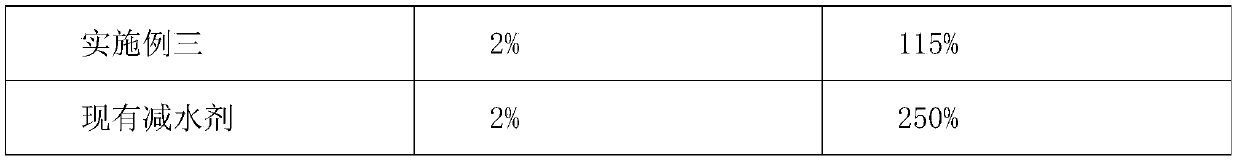

Examples

Embodiment 1

[0025] A concrete antifreeze water reducer, the formula of which contains the following components in parts by mass: 20 parts of β-naphthalenesulfonate formaldehyde condensate, 30 parts of glucose laurate, 30 parts of microcrystalline muscovite powder, and 15 parts of bentonite 20 parts of saponin, 3 parts of Artemisia gum, 5 parts of ethylene glycol, 10 parts of polysorbate, 6 parts of sodium lactate, 20 parts of isopentenol polyoxyethylene ether, 10 parts of ammonium persulfate, 10 parts of lignin parts, 3 parts of carbon fiber waste silk, and 100 parts of water.

[0026] The preparation method is as follows:

[0027] S1, first use a fine sand net to sieve 30 parts of microcrystalline muscovite powder, 15 parts of bentonite and 20 parts of saponin for subsequent use;

[0028] S2, add 50 parts of water into the mixing tank, add 20 parts of β-naphthalenesulfonate formaldehyde condensate and 30 parts of glucose laurate, and mix for 20 minutes to obtain a mixed solution A;

[...

Embodiment 2

[0035] A concrete antifreeze water reducer, the formula of which comprises the following components in parts by mass: 30 parts of β-naphthalenesulfonate formaldehyde condensate, 35 parts of glucose laurate, 40 parts of microcrystalline muscovite powder, and 20 parts of bentonite 35 parts of saponin, 4 parts of artemisia gum, 6 parts of ethylene glycol, 11 parts of polysorbate, 8 parts of sodium lactate, 30 parts of isopentenol polyoxyethylene ether, 13 parts of ammonium persulfate, and 15 parts of lignin parts, 5 parts of carbon fiber waste silk, and 150 parts of water.

[0036] The preparation method is as follows:

[0037] S1, first use a fine sand net to sieve 40 parts of microcrystalline muscovite powder, 20 parts of bentonite and 35 parts of saponin for subsequent use;

[0038] S2, add 100 parts of water into the mixing tank, add 30 parts of β-naphthalenesulfonate formaldehyde condensate and 35 parts of glucose laurate, and mix for 30 minutes to obtain a mixed solution A...

Embodiment 3

[0045] A concrete antifreeze water reducer, the formula of which comprises the following components in parts by mass: 50 parts of β-naphthalenesulfonate formaldehyde condensate, 40 parts of glucose laurate, 50 parts of microcrystalline muscovite powder, and 30 parts of bentonite 50 parts of saponin, 5 parts of Artemisia gum, 8 parts of ethylene glycol, 12 parts of polysorbate, 12 parts of sodium lactate, 50 parts of isopentenol polyoxyethylene ether, 15 parts of ammonium persulfate, 20 parts of lignin parts, 6 parts of carbon fiber waste silk, and 200 parts of water.

[0046] The preparation method is as follows:

[0047] S1, first use fine sand net to sieve 50 parts of microcrystalline muscovite powder, 30 parts of bentonite and 50 parts of saponin for later use;

[0048]S2, add 100 parts of water into the mixing tank, add 50 parts of β-naphthalenesulfonate formaldehyde condensate and 40 parts of glucose laurate, and mix for 30 minutes to obtain a mixed solution A;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com