Catalyst for polyurethane foaming, polyurethane foaming composition, foaming method and application thereof

A technology of foaming composition and polyurethane foam, which is applied in the field of materials and can solve the problems of poor heat insulation effect of foaming materials, needs to be improved, poor temperature resistance and aging resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

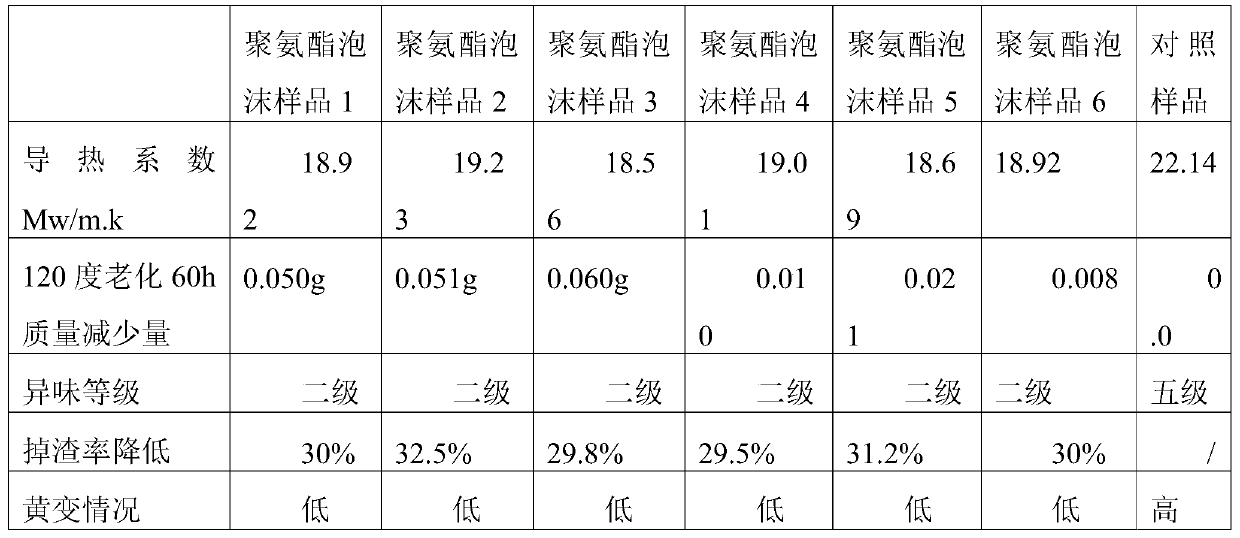

Examples

Embodiment 1

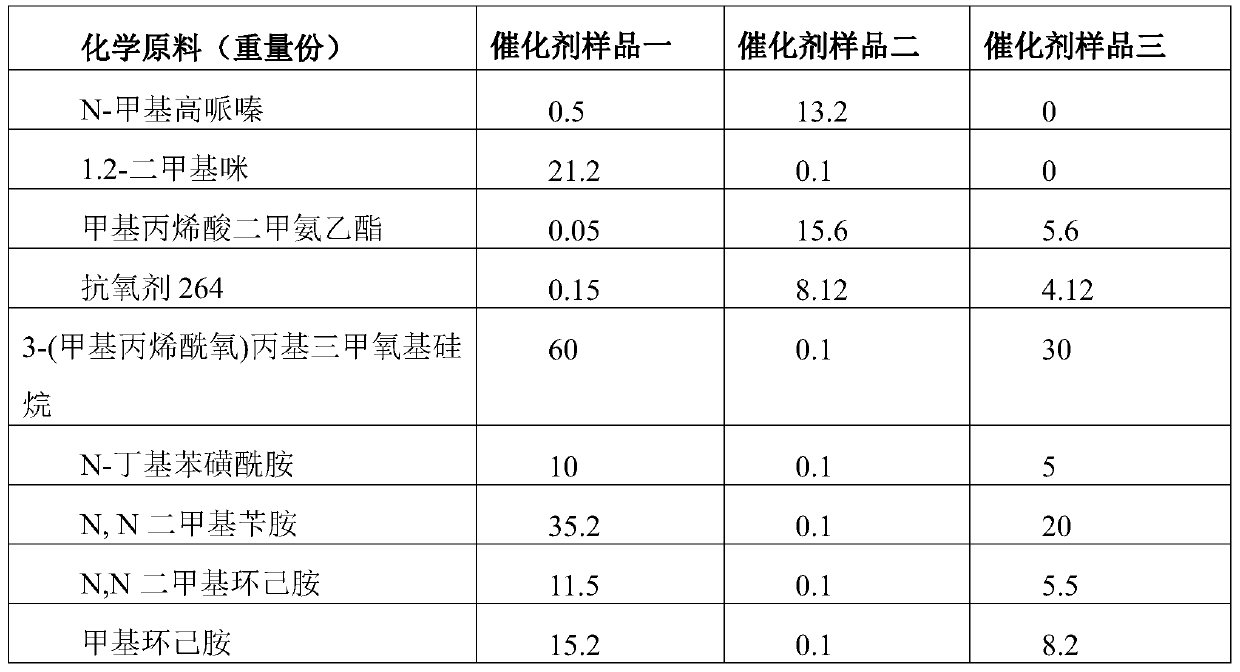

[0047] According to the formula shown in Table 1, chemical raw materials were weighed and mixed to obtain catalyst sample 1, catalyst sample 2 and catalyst sample 3 respectively.

[0048] Table 1 Catalyst sample formula

[0049]

Embodiment 2

[0051] According to the formula shown in Table 2, cyclopentane, LBA and Fa-245 foaming agent were weighed, and the weighed raw materials were mixed to obtain foaming agent sample 1 to foaming agent sample 9 respectively.

[0052] Table 2 Foaming agent sample formula

[0053] Foaming agent Cyclopentane (parts by weight) LBA (parts by weight) Fa-245(parts by weight) Blowing agent sample 1 6 2 0 Blowing agent sample 2 0 20 0 Blowing agent sample 3 8 1 2 Blowing agent sample 4 0 16 0 Blowing agent sample 5 0 0 12 Blowing agent sample 6 2 4 8 Blowing agent sample 7 2 7 6 Blowing agent sample 8 12 0 4 Blowing agent sample 9 0 12 3

Embodiment 3

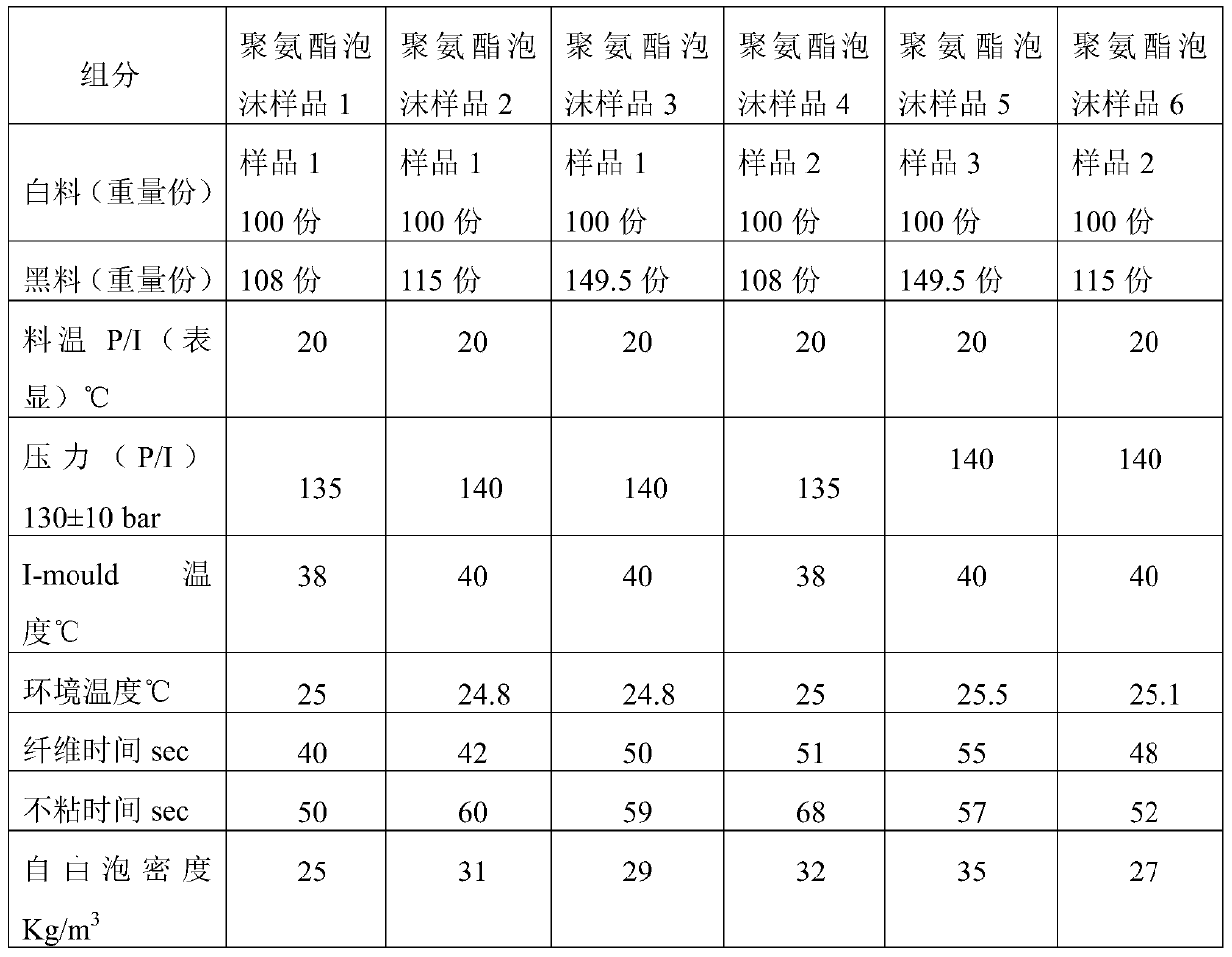

[0055] According to the formula shown in Table 3, the combined polyether polyol was mixed with the blowing agent and the catalyst to obtain white material sample 1, white material sample 2 and white material sample 3 respectively.

[0056] Table 3 white material sample formula

[0057] raw material White material sample 1 White material sample 2 White material sample 3 Foaming agent Sample 1 8 copies Sample 3 15 copies Sample 9 15 copies catalyst Sample 1 2 copies Sample 2 4.5 copies Sample three 6.9 copies Combination polyether polyol 90 copies 80.5 copies 78.1 copies

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com